Contents

Understanding why water-soluble polymer could be useful for science and manufacturing, and whether we will ever see water-soluble packaging for products

About the Author: Sakina Zeynalova is a chemist, polymer specialist, science popularizer. Works for the Italian company Tre Tau Engineering, author of the book Poisons: Around and Inside.

Saying the word “plastic”, we imagine something solid, plastic, resistant to water. It could be a food container, a plastic cup, or a window frame. But what if we told you that there are water-soluble plastics? One such water-soluble polymer is polyvinyl alcohol. At first glance, such materials may seem useless, although they are used in advanced scientific developments: biomedicine, complex 3D printing, membranes for water purification. You also regularly encounter this substance in cosmetics and in the plastics you use. In this article, we will understand what polyvinyl alcohol is and what it is used for.

What is polyvinyl alcohol?

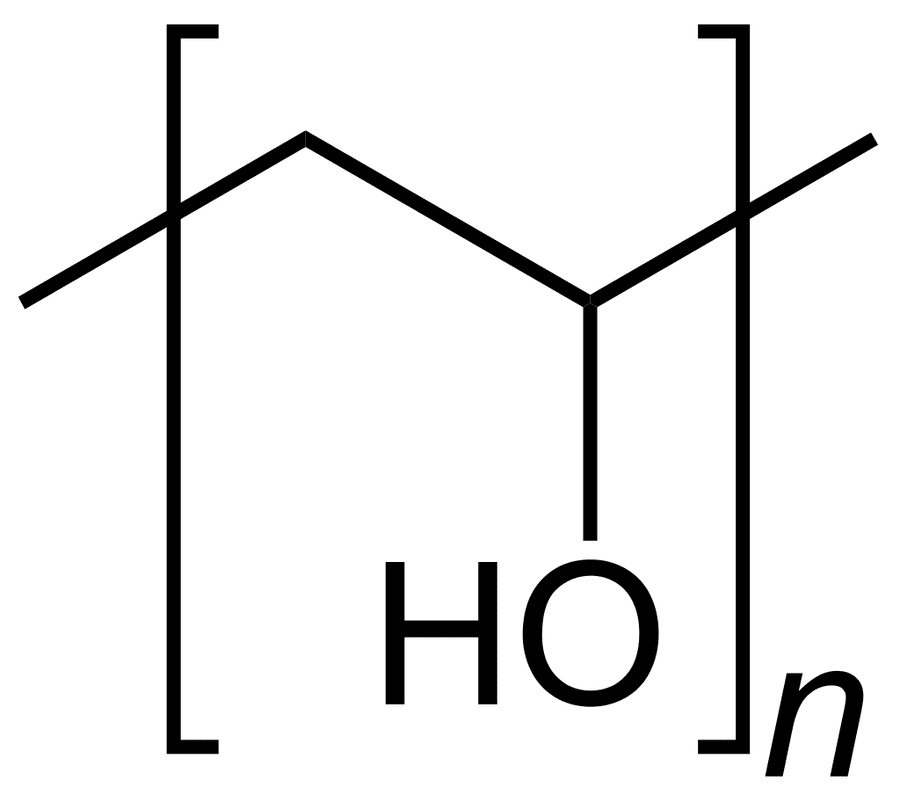

Polyvinyl alcohol (PVA, PVA) is a biocompatible, non-toxic and water-soluble synthetic (that is, artificially obtained) polymer. It consists of repeating units -CH2-SN (ON)- n, and in its pure form is supplied in the form of colorless and odorless granules. This substance actively absorbs moisture, as a result of which it loses strength, but becomes more elastic. Because of this property, it is added to other polymers as a plasticizer, a substance that improves plasticity. And if polyvinyl alcohol reacts actively to water, then it is stable with respect to oils, fats and organic solvents.

Polyvinyl alcohol is obtained mainly from polyvinyl acetate, better known to us as PVA (the same glue is made on its basis), using various saponification options. The result is a polymer having many alcohol groups. It is they who provide the special properties of this substance.

It is important to note that among all the characteristics of PVA, we did not mention “biodegradable” for a reason. Despite the fact that the polymer dissolves in water, this does not mean at all that when it enters the environment in this form, it breaks down to water, carbon dioxide and safe organics. Unmodified PVA is sufficiently resistant to biodegradation, so it is proposed to add other components to it, for example, polysaccharides. They contribute to the acceleration of this process, as they are a source of nutrition for microorganisms.

Areas of use

Packaging

The very idea of water-soluble plastic sounds extremely attractive. Just imagine: you use disposable packaging and after that you don’t worry where to take it for recycling: you dissolve it in water and that’s it.

Some studies indicate that this type of material is underestimated by the scientific community. After all, such polymers do not need to be recycled, they can be used as a safe film for food products. At the end of their service life, they can be disposed of by dissolving in water.

However, this is a deceptive simplicity: the polymer does not break down in water, but dissolves. Therefore, the question of its disposal is still worth it. In addition, in its pure form, polyvinyl alcohol is not in a hurry to decompose in the environment, it needs some modifications.

How can I do that? PVA can be chemically modified or a filler added to alter its properties. And if there were questions about films made from pure polyvinyl alcohol (they lose their barrier properties under the action of water, which is not very convenient for packaging materials), then by filling the polymer with cellulose and an alkyl ketone dimer, it is possible to increase the mechanical strength of the film by almost 1,5 times and give it is resistant to water, water vapor and ultraviolet. At the same time, the rate of biodegradation of the material only increases. The film based on polyvinyl alcohol can be given additional antibacterial and antifungal properties. Combining PVA and xanthan gum, you can get a composite material that is quite suitable for food packaging, the decomposition time of such a package is only 12 hours. And modified chitosan + PVA gives an excellent biodegradable, anti-fog film for products with an antibacterial effect.

Purely theoretically, a PVA film can be dissolved and drunk. The results of a study of the toxicity of polyvinyl alcohol in freshwater fish showed no significant effects. However, this does not mean that such actions will be beneficial for your health.

3D printing

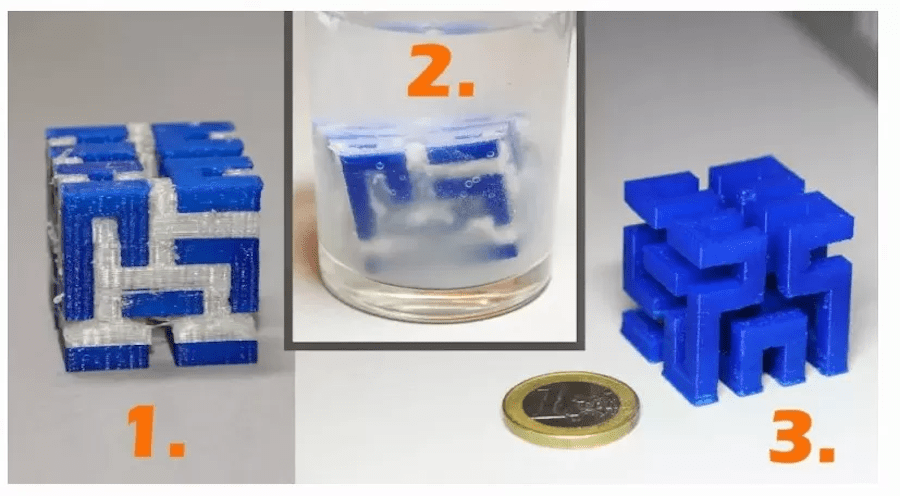

Due to the property of water solubility, it is impractical to create any products from PVA on a 3D printer. But this same property has made it a sought-after material in additive technology. The fact is that printing geometrically complex shapes always requires support structures. These elements are removed after the print has been completed, and if the support was made of too strong a material, then it must be cut down. This operation may damage the main structure or completely break it. Therefore, water-soluble polyvinyl alcohol as a support material for 3D printing has become especially popular.

Biomedicine

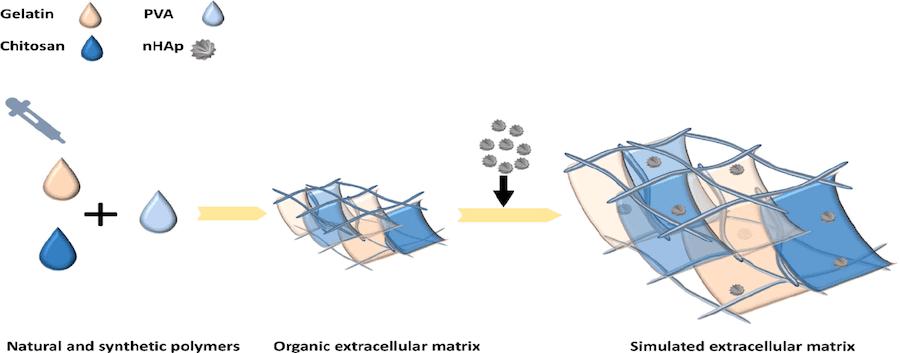

This is one of the largest and most dynamically developing directions for the use of polyvinyl alcohol. No wonder: polyvinyl alcohol becomes the basis of multicomponent scaffolds for bone tissue replacement. Gelatin, chitosan, and hydroxyapatite may also be included in the composition of such materials, which ultimately accelerates the healing of bone injuries.

There are a lot of hopes for combining polyvinyl alcohol with biopolymers from crustacean shells – chitin and chitosan: here you have safe use inside the body, and antibacterial effects and non-toxicity. Taking into account the plasticity of the obtained material, it is possible to make not only bone implants, but also films, sponges, and much more. There are even options for its use as an absorber of radioactive beta radiation.

Polyvinyl alcohol has long been widely used in soft contact lenses, eye drops, vascular surgery, and as artificial cartilage and meniscus. For example, ear implants are made from PVA.

Based on PVA, hydrogels are made that are sensitive to changes in acidity and temperature and are capable of targeted drug delivery, including anticancer drugs. Also for these purposes, micro- and nanoparticles of PVA with various additives loaded with the same preparations are used. Together with non-toxicity and biocompatibility, these “superpowers” of polyvinyl alcohol make it extremely attractive for selective drug delivery.

Also, antibacterial films based on polyvinyl alcohol are used for wound healing or tumor treatment.

Cosmetics

You can find polyvinyl alcohol in some cosmetics as a thickener and film former. This substance is used everywhere: from cleansers to decorative cosmetics. It is safe, non-toxic and rarely causes an allergic reaction.

Other areas

The smallest filter films based on cross-linked PVA separate salt components well from water, so they could be used for desalination systems, drinking water treatment and just wastewater treatment. Polyvinyl alcohol is used to create synthetic fibers, as an additive to polymers, to immobilize (that is, immobilize) cells in microbiology, and to synthesize other polymers. The areas of application of PVA are expanding every year.

The result?

- In fact, it turns out that water-soluble polymers can be very useful.

- Polyvinyl alcohol has found application in a variety of fields.

- In some places, it is already being successfully used to solve various problems (3D printing, medicine, etc.) and has firmly taken its place.

- To solve some problems, specific methods of using polyvinyl alcohol have yet to be developed. For example, to create more environmentally friendly plastic packaging.

- Definitely, the scope of its application in the coming years will only expand and we will meet polyvinyl alcohol more often.