Contents

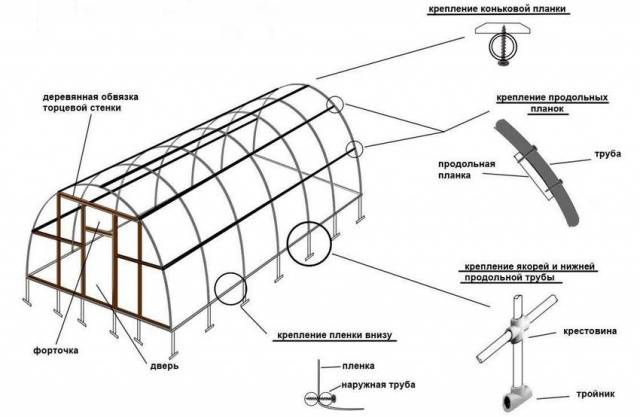

The basis of the greenhouse is the frame. It is made from wooden slats, metal pipes, profiles, corners. But today we will consider the construction of a frame from a plastic pipe. In the photo, a drawing will be provided for each model for a better idea of the constituent parts of the structure. So, let’s find out how a do-it-yourself greenhouse is made from plastic pipes, and what shape the buildings are.

Existing varieties of greenhouses made of plastic pipes

The design of each greenhouse consists of almost the same components. Only the size of the structure and the scheme of the roof differ, which can be arched, shed or gable. The photo shows different options for frame designs made of plastic pipes. According to them, you can create a drawing of your future greenhouse.

For greenhouses with arched roofs, the lower base – the box is assembled from wood. Usually the entrance is boards or timber. Pipes are fixed to metal pins fixed in the ground. Sometimes the rods are replaced with wooden stakes, but this design will turn out to be short-lived. The pin protrudes from the ground by about 400 mm in height. Its thickness should correspond to the inner diameter of the tubes. If the made frame will be covered with PET film, the ends of the structure should be optimally made of plywood or other similar material. They cut through the door and vents. In the event that a polycarbonate greenhouse will decorate your yard, the ends are sewn up with the same material.

Frame structures with a gable and single-pitched roof are sheathed with polycarbonate and polyethylene. Glass used to be used, but the high cost and fragility of the material made it less popular. Gable and single-pitched frames for better rigidity are fixed to a rigid base.

Construction of an arched greenhouse greenhouse from polypropylene pipes

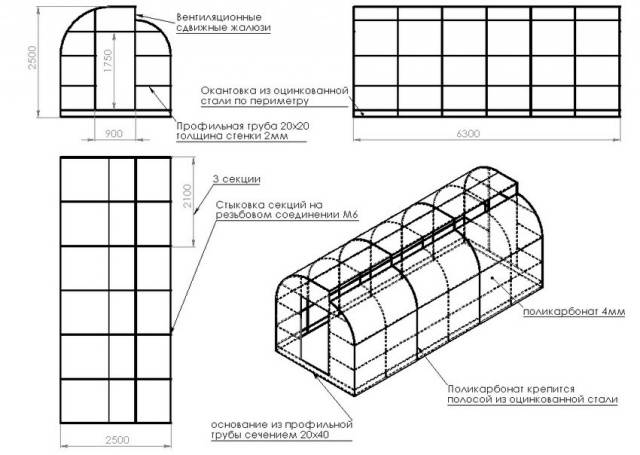

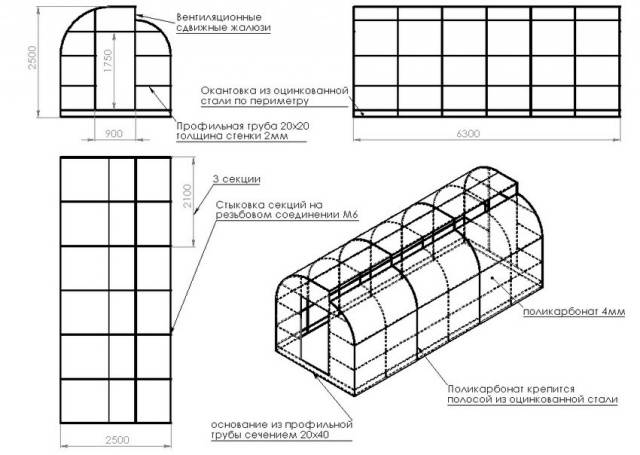

The easiest way is to build a greenhouse from purchased blanks. Polypropylene pipes come in a set cut to a certain size with fasteners and fittings. Below in the photo you can see a drawing of one of these greenhouses. The frame is assembled as a constructor. Under it, a foundation is not required, it is enough just to level the site. If a greenhouse is made from plastic pipes with your own hands, you are given the opportunity to choose an individual size.

Choosing the right location for the greenhouse

A greenhouse or greenhouse of an arched structure made of polypropylene pipes must be correctly positioned on its site:

- it is optimal for the construction to choose a sunny place, unshaded by tall trees and buildings;

- it is necessary to provide a convenient approach to the greenhouse;

- it is advisable to install a greenhouse in a less windy area.

A gardener who has built a greenhouse in compliance with these nuances will receive a structure with minimal heat loss.

Step-by-step instructions for building a greenhouse from polypropylene pipes

Even before the start of construction, it is necessary to level the area under the greenhouse. It is desirable to loosen or compact the soil as little as possible so as not to disturb its structure. According to the finished drawing, the required amount of material is bought. Polypropylene pipes are suitable with a diameter not thinner than 20 mm. For end strapping, you will need a wooden beam, plywood or any other sheet material.

So, having at hand all the materials and drawing, proceed to the construction of the greenhouse:

- A simple option for attaching an arched frame, especially for a small greenhouse, is the pin method. The prepared site is marked out, transferring the dimensions of the future frame. Metal rods are driven into the ground along the marking lines of the side long walls of the greenhouse. The strength of the frame depends on the distance between the rods. The rarer the step, the more stable the greenhouse will turn out. A box is knocked down from a board or a wooden beam around the perimeter of the frame. Polypropylene pipes are bent in an arc and placed on the pins of opposite walls. In the final, you should get a skeleton of arcs fixed to a wooden frame.Council! The distance between the arcs for polycarbonate can be made larger. The weight and strength of the material will make the greenhouse heavy, stable, strong. A small step of the arcs under the film will not only strengthen the design, but also reduce the sagging of the film.

For fastening the end walls, a frame is assembled from a bar with a section of 50×50 mm. The frame of the front wall is made taking into account the door and the window. On the back wall, only a window is usually provided, but you can install another door to make the greenhouse passable. Wooden end frames are fixed to a common skeleton of arcs. Additional stiffening elements are installed from the beam. At the highest point of the arcs along the frame, the upper element of the screed of the entire structure is fixed with clamps.

- When the frame of the greenhouse is completely ready, a PET film is pulled over it. Below it is nailed with nails and wooden planks. On the body, fixation starts from the middle, gradually moving to the corners. At the ends of the greenhouse, the edges of the film are collected with an accordion and also nailed to a wooden frame.Council! To make a greenhouse made of plastic pipes less likely to have to be blocked, it is better to use multilayer or reinforced polyethylene.

- The end side can be sewn up with any sheet material, but it is better to make the walls also transparent so that more light enters the greenhouse. For the manufacture of film ends from polyethylene, fragments of upholstery of doors and vents are cut out. They are attached to a wooden frame with planks or staples of a construction stapler.

On this, the greenhouse made of plastic pipes is ready, you can proceed to its internal arrangement.

The video shows the process of assembling a greenhouse from plastic pipes:

Arched greenhouse made of plastic pipes and polycarbonate

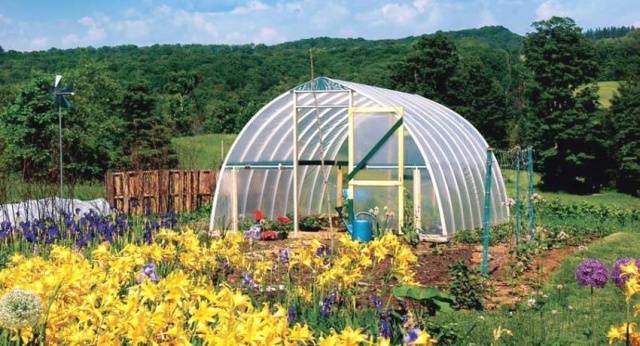

A big plus of plastic pipes is their long service life. So, it is necessary that the coating of the greenhouse meets the same standards. Any film will have to be changed every season or even every year. Polycarbonate is an ideal material for greenhouse cladding. The structure will be durable, warm and will last for many years. The photo below shows a drawing of a typical arched greenhouse covered with polycarbonate.

We choose a place on the site, the type and size of the greenhouse

If a film greenhouse can be called a temporary structure, then a polycarbonate structure is more difficult to disassemble in order to be moved to another location. Here you immediately need to think about its permanent location. The selection of a site is carried out according to the same rules as for a film greenhouse – a bright sunny place with a convenient approach. In a greenhouse made of plastic pipes sheathed with polycarbonate, you can grow vegetables even in winter. In this case, you will have to provide a heating system.

The shape and size of the greenhouse is determined by personal preference. The heavier the structure, the more powerful the foundation must be made for it. Usually the size of the greenhouse is determined by the number of crops grown. It is not recommended to build large structures due to the difficult maintenance of the internal microclimate. It is optimal for polycarbonate greenhouses to build arched roofs 2 m high. The common width and length of the building is 3×6 m, and the path between the beds must be taken into account. Its optimal width ranges from 600 mm. This is enough for a convenient arrangement of the front door.

Construction of the base for the frame of the greenhouse

A concrete base for a polycarbonate greenhouse is considered reliable. However, under a small home greenhouse, you can make a wooden base from a bar with a section of 100×100 mm. To make the wood less susceptible to decay, it is treated with an antiseptic, and then knocked into a frame with the help of staples.

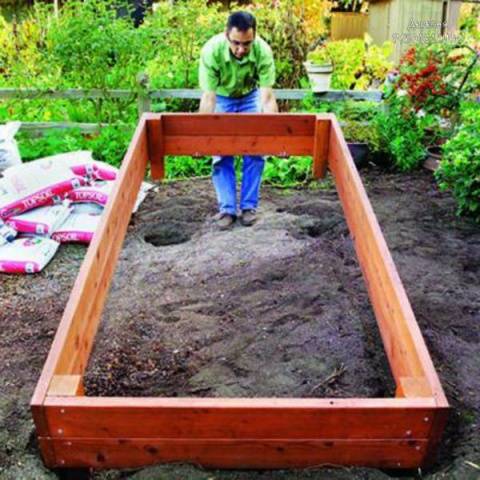

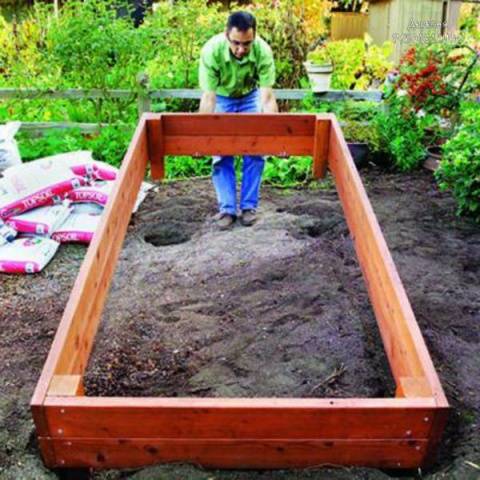

A trench must be prepared under the wooden box. On a flat piece of land, wooden stakes are driven in, indicating the dimensions of the structure. They are connected to each other with a construction cord, and the diagonals are also checked so that the distance between the corners is the same. If the rectangle turned out to be correct, then the markup is correct.

The depth of the trench is determined by the height of the future wooden box. It should protrude 50% out of the ground. The bottom is leveled and covered with a 50 mm layer of sand. A wooden box treated with an antiseptic must be additionally protected from moisture. To do this, take the roofing material and wrap the entire structure. It is necessary that the strips overlap.

It remains to lower the finished box into the trench, level it, fill it with soil and ram it.

Making a frame from plastic pipes

The frame of plastic pipes for polycarbonate sheathing is assembled in the same way as for a film greenhouse. However, there are some nuances that we will now try to cover:

- It is necessary to take the reinforcement with a thickness along the inner diameter of the plastic pipe and cut it into pieces of 800 mm. The prepared pins are driven close to the buried box along the long walls so that they peek out of the ground by 350 mm. Between the rods maintain a step of 600 mm. Be sure to ensure that the opposite rods at both walls are located strictly against each other, otherwise the arcs put on them will turn out to be oblique.

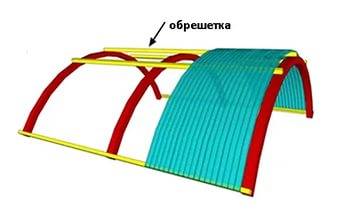

- Plastic pipes are bent in an arc, putting on the driven rods of opposite walls. Each lower end of the pipe is fixed with metal clamps to a wooden box. According to the assembled skeleton along all arcs, stiffeners are laid out. In the future, they will play the role of crates. The connection of these elements is carried out with plastic clamps.

- To fix the polycarbonate at the ends of the greenhouse, you will also need a crate. Its manufacture begins from the installation of racks at the ends of the building. Take 4 bars with a section of 20×40 mm on each side. Two central posts are installed at a distance from each other, equal to the width of the window and the door. Between themselves, the racks are fastened with transverse slats.

When the frame is fully completed, you can begin to sheathe it with polycarbonate.

Covering the arched greenhouse with polycarbonate

Covering an arched greenhouse with polycarbonate is quite simple. Lightweight sheets bend perfectly, they can be shaped into a frame and mounted independently without outside help. The sheet is laid on the frame with a protective film up. With a step of 45 mm, holes are drilled along the sheet with a diameter of 1 mm more than the thickness of the self-tapping screw. They begin to fix the sheet from the bottom up, at the same time bending around the arcs with polycarbonate. We must not forget to use press washers along with self-tapping screws.

Docking of adjacent sheets to each other occurs with the help of connecting strips. Corner joints are fixed with a special corner profile.

When the entire frame is completely sheathed, it will be possible to remove the protective film from the polycarbonate.

The use of HDPE pipes for the manufacture of greenhouses on a concrete foundation

HDPE pipes are cheap and easy to use. They are sold in coils or in pieces. It is more profitable to take a bay to get rid of excess waste. Let’s look at another option on how to make a greenhouse from HDPE plastic pipes on a strip foundation.

Having made a marking of the future greenhouse on the prepared site, they dig a trench under the foundation with a width of 300 mm and a depth of 500 mm. The bottom is covered with a 100 mm layer of a mixture of sand and gravel. Formwork is built around the trench from old boards, a reinforcing belt is laid out from metal rods inside the pit and everything is poured with a concrete solution. To make the foundation monolithic, it is concreted in 1 day. The solution is prepared from cement, sand and gravel in a ratio of 1:3:5, bringing it to the consistency of sour cream.

While the concrete will harden, proceed to the manufacture of the frame. First, the lower box is knocked down from a wooden beam. To it, with the help of self-tapping screws and clamps, arcs from HDPE pipes are fixed. Along the resulting skeleton, plastic clamps are used to fasten stiffeners from the same HDPE pipe. It is enough to lay three such ribs, one in the center and one on each side.

The finished structure with the help of dowels and metal corners is fixed to a completely frozen foundation. For waterproofing, a layer of roofing material is placed between the concrete and the wooden box. Further work is aimed at the installation of end walls and sheathing with film or polycarbonate. The procedure is carried out in the same way as for the greenhouse options already considered.

The video shows the installation of a greenhouse made of plastic pipes:

Смотрите это видео на YouTube

The gardener is independently able to build each of the considered greenhouses on his site. Plastic pipes are light, bend well, which allows you to make a frame without outside help.