Contents

Hovercraft is a vehicle capable of moving both on water and on land. Such a vehicle is not at all difficult to do with your own hands.

What is a “hovercraft”?

This is a device where the functions of a car and a boat are combined. As a result, we got a hovercraft (HV), which has unique off-road characteristics, without loss of speed when moving through water due to the fact that the hull of the vessel does not move through the water, but above its surface. This made it possible to move through the water much faster, due to the fact that the friction force of the water masses does not provide any resistance.

Although the hovercraft has a number of advantages, its scope is not so widespread. The fact is that not on any surface this device can move without any problems. It needs soft sandy or soil soil, without the presence of stones and other obstacles. The presence of asphalt and other solid bases can cause damage to the bottom of the vessel, which creates an air cushion when moving. In this regard, “hovercraft” are used where you need to swim more and drive less. On the contrary, it is better to use the services of an amphibious vehicle with wheels. The ideal conditions for their use are impassable swampy places where, apart from a hovercraft (Hovercraft), no other vehicle can pass. Therefore, SVPs have not become so widespread, although rescuers of some countries, such as Canada, for example, use such transport. According to some reports, SVPs are in service with NATO countries.

How to purchase such a transport or how to make it yourself?

Hovercraft is an expensive type of transport, the average price of which reaches 700 thousand rubles. Transport type “scooter” is 10 times cheaper. But at the same time, one should take into account the fact that factory-made vehicles are always of better quality compared to homemade ones. And the reliability of the vehicle is higher. In addition, factory models are accompanied by factory warranties, which cannot be said about designs assembled in garages.

Factory models have always been focused on a highly professional direction, connected either with fishing, or with hunting, or with special services. As for homemade SVPs, they are extremely rare and there are reasons for this.

These reasons include:

- Pretty high cost, as well as expensive maintenance. The main elements of the apparatus wear out quickly, which requires their replacement. And each such repair will result in a pretty penny. Only a rich person will allow himself to buy such an apparatus, and even then he will think once again whether it is worth contacting him. The fact is that such workshops are as rare as the vehicle itself. Therefore, it is more profitable to purchase a jet ski or ATV to move on water.

- The working product creates a lot of noise, so you can only move around with headphones.

- When driving against the wind, the speed drops significantly and fuel consumption increases significantly. Therefore, homemade SVPs are more of a demonstration of their professional abilities. The vessel not only needs to be able to manage, but also be able to repair it, without significant costs.

How to Build inflatable Hovercraft “THUNDER” Air Cushion Vehicles ACV

Do-it-yourself SVP manufacturing process

Firstly, it is not so easy to assemble a good SVP at home. To do this, you need to have the ability, desire and professional skills. Technical education will not hurt either. If the latter condition is absent, then it is better to abandon the construction of the apparatus, otherwise you can crash on it at the first test.

All work begins with sketches, which are then transformed into working drawings. When creating sketches, it should be remembered that this apparatus should be as streamlined as possible so as not to create unnecessary resistance when moving. At this stage, one should take into account the factor that this is, in fact, an air vehicle, although it is very low to the surface of the earth. If all conditions are taken into account, then you can begin to develop drawings.

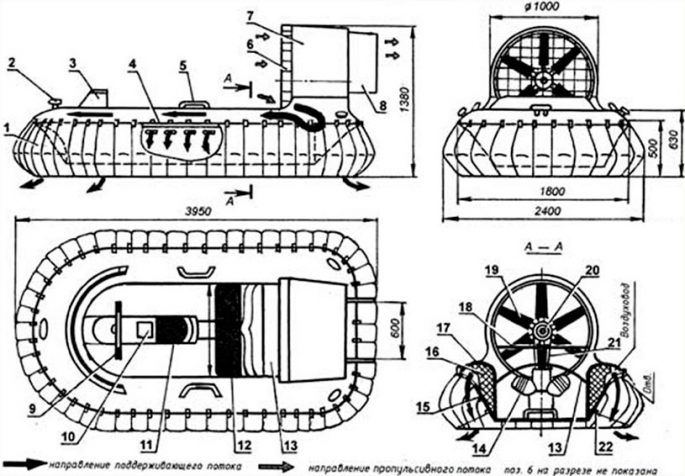

The figure shows a sketch of the SVP of the Canadian Rescue Service.

Technical data of the device

As a rule, all hovercraft are capable of a decent speed that no boat can reach. This is if we take into account that the boat and the SVP have the same mass and engine power.

At the same time, the proposed model of a single-seat hovercraft is designed for a pilot weighing from 100 to 120 kilograms.

As for the control of the vehicle, it is quite specific and, in comparison with the control of a conventional motor boat, does not fit in any way. The specificity is associated not only with the presence of high speed, but also with the method of movement.

The main nuance is related to the fact that on turns, especially at high speeds, the ship skids heavily. To minimize this factor, it is necessary to lean to the side when cornering. But these are short-term difficulties. Over time, the control technique is mastered and miracles of maneuverability can be shown on the SVP.

What materials are needed?

Basically, you will need plywood, foam plastic and a special design kit from Universal Hovercraft, which includes everything you need to assemble the vehicle yourself. The kit includes insulation, screws, air cushion fabric, special adhesive and more. This set can be ordered on the official website by paying 500 bucks for it. The kit also includes several options for drawings for assembling the SVP apparatus.

Basically, you will need plywood, foam plastic and a special design kit from Universal Hovercraft, which includes everything you need to assemble the vehicle yourself. The kit includes insulation, screws, air cushion fabric, special adhesive and more. This set can be ordered on the official website by paying 500 bucks for it. The kit also includes several options for drawings for assembling the SVP apparatus.

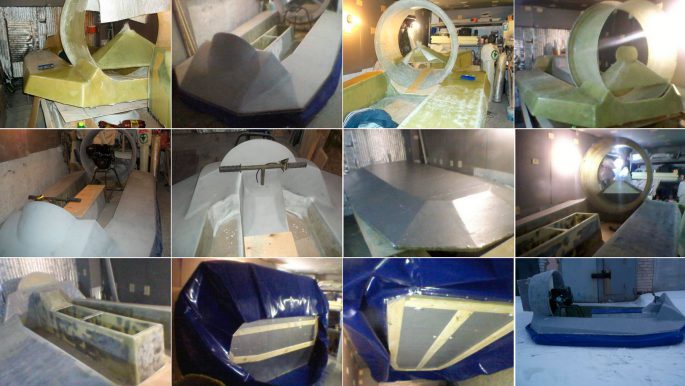

How to make a body?

Since the drawings are already available, the shape of the vessel should be tied to the finished drawing. But if there is a technical education, then, most likely, a ship will be built that does not look like any of the options.

The bottom of the ship is made of foam plastic, 5-7 cm thick. If you need an apparatus for transporting more than one passenger, then another such foam sheet is attached from below. After that, two holes are made in the bottom: one is for air flow, and the second is for providing air to the pillow. Holes are cut with an electric jigsaw.

At the next stage, the lower part of the vehicle is sealed from moisture. To do this, fiberglass is taken and glued to the foam using epoxy glue. In this case, irregularities and air bubbles may form on the surface. To get rid of them, the surface is covered with polyethylene, and on top also with a blanket. Then, another layer of film is placed on the blanket, after which it is fixed to the base with adhesive tape. It is better to blow air out of this “sandwich” using a vacuum cleaner. After 2 or 3 hours, the epoxy will harden and the bottom will be ready for further work.

The top of the hull can have an arbitrary shape, but take into account the laws of aerodynamics. After that, proceed to attach the pillow. The most important thing is that air enters it without loss.

The pipe for the motor should be used from styrofoam. The main thing here is to guess with the dimensions: if the pipe is too large, then you will not get the thrust that is necessary to lift the SVP. Then you should pay attention to mounting the motor. The holder for the motor is a kind of stool, consisting of 3 legs attached to the bottom. On top of this “stool” the engine is installed.

What engine is needed?

There are two options: the first option is to use the engine from the company “Universal Hovercraft” or use any suitable engine. It can be a chainsaw engine, the power of which is quite enough for a home-made device. If you want to get a more powerful device, then you should take a more powerful engine.

It is advisable to use factory-made blades (those in the kit), as they require careful balancing and it is quite difficult to do this at home. If this is not done, then the unbalanced blades will break the entire engine.

Hovercraft first flight

How reliable can an SVP be?

As practice shows, factory hovercraft (SVP) have to be repaired about once every six months. But these problems are minor and do not require serious costs. Basically, the pillow and the air supply system fail. In fact, the likelihood that a homemade device will fall apart during operation is very small if the “hovercraft” is assembled correctly and correctly. For this to happen, you need to run into some obstacle at high speed. Despite this, the air cushion is still able to protect the device from serious damage.

Rescuers working on similar devices in Canada repair them quickly and competently. As for the pillow, it can really be repaired in an ordinary garage.

Such a model will be reliable if:

- The materials and parts used were of good quality.

- The machine has a new engine.

- All connections and fastenings are made reliably.

- The manufacturer has all the necessary skills.

If the SVP is made as a toy for a child, then in this case it is desirable that the data of a good designer be present. Although this is not an indicator for putting children behind the wheel of this vehicle. It’s not a car or a boat. Managing SVP is not as easy as it seems.

Given this factor, you need to immediately begin to manufacture a two-seater version in order to control the actions of the one who will drive.

Homemade hovercraft