Contents

There are situations when, due to heavy employment, an urgent business trip, or a breakdown of the moonshine still, the distiller cannot immediately overtake the fermented mash, postponing the process for 7-14, and sometimes 20-30 days. There is nothing wrong with this, with the proper organization of the storage process, the mash can stand without consequences for several weeks.

Theory

Deterioration of the properties of mash can occur for the following reasons:

1. Acidification

After fermentation stops, the yeast stops producing carbon dioxide, which pushes out oxygen. If the mash comes into contact with air, then the ingress of oxygen into the wort causes souring – aerobic microorganisms are activated, they process the alcohol in the mash into water and acid. As a result, the yield of moonshine is reduced and a sour taste appears.

In order to prevent the mash from souring in storage, it is necessary to protect the access of oxygen by keeping the container hermetically closed or under a water seal.

2. Yeast by-products

When processing sugars in the wort, yeast, in addition to alcohol and carbon dioxide, also emits other substances, many of which worsen the quality of the mash.

Interestingly, it is the fermented mash that accumulates the most harmful impurities – when sugar runs out, the yeast begins to eat their dead relatives or find other food sources from the remains of plant materials.

It is necessary to destroy the yeast or create unfavorable conditions under which they will go into suspended animation (“fall asleep”). To do this, the fermented mash is removed from the sediment, clarified (preferably) and stored in the cold, but not at sub-zero temperatures.

For clarification, it is best to add vodka, alcohol or tails from the previous distillation to the mash. As a result, the concentration of ethyl alcohol will increase and this will become an obstacle to the activation of yeast and harmful microorganisms.

You can kill yeast by pasteurization, but in terms of labor and time, this process is comparable to distillation, so it is often impractical.

3. Decomposition of plant residues

Typical for fruit and grain mash. The remains of raw materials accumulate along with dead yeast in the form of sediment at the bottom. Sooner or later, this sediment begins to decompose (rot) or becomes a source of reserve nutrition for yeast. Both options negatively affect the quality of moonshine. This is another reason why the mash that has won back must be removed from the sediment (decanted) before storage.

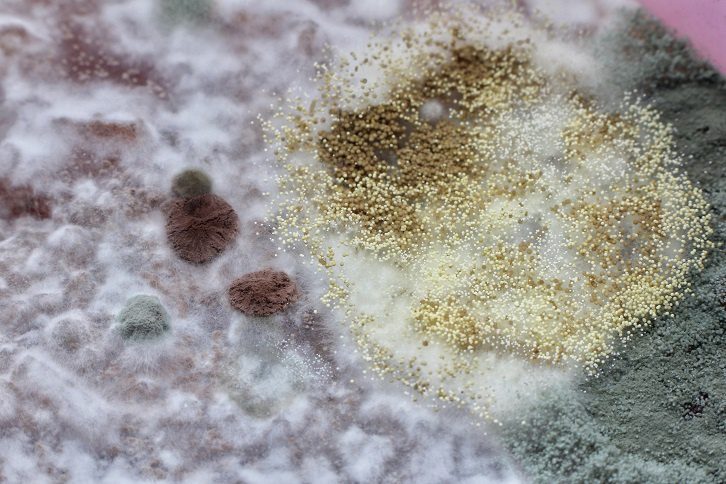

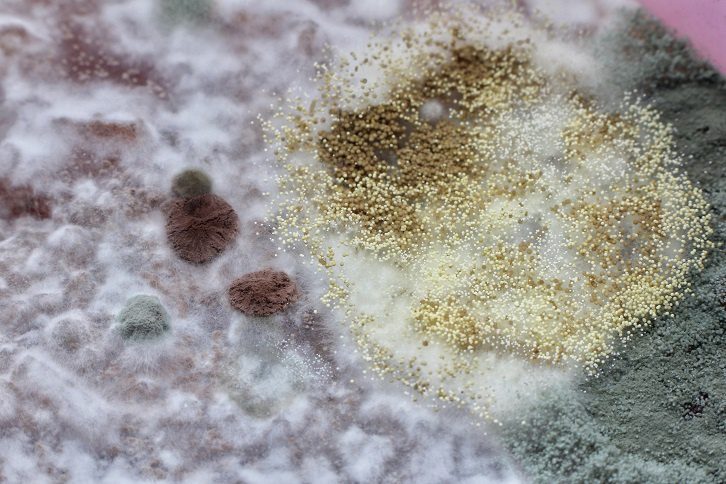

4. Activation of other microorganisms

In addition to acetic bacteria, other microorganisms can also spoil the mash, which, depending on the raw material, cause mold, milk, oil, and even glycerin fermentation.

The main method of combating pathogenic microflora is the sterilization of equipment and containers. And when storing the mash, the absence of oxygen access, fixing with ethyl alcohol and decanting the sediment help.

Technology for preparing mash for storage

Sequencing:

- Make sure that the mash has fermented. Although the strict execution of the following steps of this instruction is guaranteed to stop fermentation, but the lack of fermentation is fraught with a decrease in yield and, possibly, not so rich taste and aroma of fruit and grain moonshine.

- Remove the mash from the sediment: using a straw, pour into another plastic or glass container, trying not to touch the sediment at the bottom.

- Lighten. This step is desirable but not required. It is best to add vodka, alcohol or “tails” from the previous distillation to the mash. It is necessary to raise the fortress to 16-18% vol in order to “preserve” yeast and other microorganisms. If we assume that the mash has fermented and gained a strength of 12%, then 4-8% pure alcohol is required per liter, the formula for calculating the amount. At the same time, it is important to remember that it is better not to pour grain distillates into fruit and berry mashes, as they can kill a light aroma. There are other methods for clarifying the mash, but they are not suitable for every raw material.

- Hermetically close the mash or put under a reliable water seal.

- Move the container to a dark room with a temperature of + 12-15 ° C (preferably + 2-5 ° C). The main thing is to prevent the temperature from dropping below zero and rising beyond the specified range.

- Leave the mash alone until distillation. Remove from the precipitate again before distillation.

Attention! If the mash remains at least a little sweet and during storage the temperature may rise above +14 ° C, then it is necessary to install a water seal, otherwise carbon dioxide from possible re-fermentation can break the container.

Shelf life of mash

The storage time without deterioration depends on the raw material and cannot be accurately predicted. In any case, the earlier the distillation is done, the lower the risk.

A universal rule: the lighter the mash and the lower the ambient temperature, the longer the shelf life.

The easiest way is with pure sugar mash, since it contains almost no vegetable impurities. Such mash can be stored for 6 months or longer.

The most difficult case is grain mash, which is often very difficult to filter. It is better not to keep grain mash for more than 14 days, but this does not mean that after the specified period everything is lost, you need to distill, but the quality of moonshine may be worse.

In terms of shelf life, in the middle are fruit and berry brews, which can stand for several months, subject to high-quality filtration, in fact, this is wine. The problem is that not every raw material can be removed vegetable impurities. For example, most apple and grape mash can be stored longer if the fruits are not overripe (the pectin content is negligible), but peach or apricot mash will begin to lose its properties faster.