Contents

Processing lumber, inserting loops, making technological holes and recesses, woodcarving – all this can be done by such a device as a milling cutter. Moreover, this can be done not only by professional equipment, but also by relatively inexpensive manual specimens. But working with a manual wood router requires knowledge of some techniques and rules. All this is in the article.

What is a cutter and what is it for?

A milling cutter is a device for processing wood or metal. They process flat and shaped surfaces, and also forms technological recesses – a groove, a comb, recesses for installing hinges, etc. According to the installation method, there are stationary machines (there are different types for performing different operations), and there are manual milling machines. Manual electric milling cutters are a universal tool that allows you to carry out any operation. To change the operation, you just need to change the nozzle – the cutter and / or its location on the part.

Machine tools are mainly used in mass production. In them, the cutter is installed motionless, and the workpiece moves along a certain trajectory. When working with a manual milling cutter, the situation is the opposite – the workpiece is fixed motionlessly, the milling cutter is moved. When processing large volumes of identical parts, it is more convenient to fix a hand router on a horizontal surface, making something similar to a milling machine.

There are many different types of milling machines, but for the home DIYer or for semi-professional use, universal ones are more suitable. They are equipped with various cutters and special devices, which allows you to perform any operation. It just takes more time and skill to complete them than on a specialized machine.

What can be done with a manual milling cutter:

- grooves and recesses of any shape (curly, rectangular, complex shapes);

- holes through and blind;

- process the edges and ends (can be made straight, can be curly);

- cut intricate details;

- apply inscriptions, patterns, drawings to the surface;

- copy details.

Copying details is one of the possibilities of an electric mill

Similar operations are used in carpentry, in the manufacture and assembly of furniture. Even embed a lock or hinges on the door – this can also be done by a manual milling cutter. Moreover, it will do it much faster and more elegantly than similar operations, but performed with a hand tool.

Preparation for work and care

To understand the principles of working with a manual router, it is desirable to have at least a general idea of its structure and the purpose of the parts.

The structure and purpose of the main nodes

The manual electric milling cutter consists of a housing in which the motor is hidden. A holder protrudes from the body, where the collets are inserted. Collets are small adapters that allow the use of cutters with different shanks. A cutter is already inserted into the collet and tightened with a clamping bolt (on some models it is fixed with a button).

Another important detail of a hand router is the platform, which is connected to the body with two rods. The platform is usually made of metal. There is a sliding plate on the underside of the platform. It is made of a smooth material that ensures the tool runs smoothly as it moves through the part.

Setting the parameters of the milling cutter is done using:

- Handles and jackals for setting the depth of milling. The tuning step is 1/10 mm.

- Adjustment of the number of revolutions. Changes the rotation speed of the cutter. For starters, it’s worth trying to work at low or medium speeds – it’s easier to drive the tool at first.

Also, be sure to have an on / off button on the case, there may also be a lock button. Here, in a nutshell, are all the nodes. In addition, there is also a parallel stop that is quite convenient to use. It can be simple or adjustable – you can move the cutting part slightly to the right or left.

Care

From the factory, the equipment is lubricated, so in principle, no additional operations are required. But it is necessary to keep the equipment clean – it is necessary to clean the dust more often, change the lubricant if necessary. Lubrication is needed for moving parts – guides. You can use liquid aerosol lubricants (preferably), but you can also use ordinary grease-type “Litol”. But, when using thick lubricants, they will have to be removed periodically, as chips and dust stick, it becomes difficult to work. When using light aerosol formulations, there is practically no sticking.

In order for the sole to slide easily, you can lubricate it with silicone grease. This is especially useful when working with templates. Then the tool literally glides, goes smoothly and without jerks.

Rotational speed

Work with a manual milling cutter on wood, composite, plywood, etc. starts with setting the basic parameters. First you need to set the rotation speed. It is selected depending on the selected cutter and the rigidity of the material and the characteristics of the router, so exact recommendations should be sought in the instruction manual.

Fixing the cutter

Next, a cutter is installed. Most branded cutters have marks that you can navigate. If they are not available, then the minimum must be clamped at least 3/4 of the length of the shank (cylindrical part). Insert the cutter to the required depth (if necessary, having previously installed a collet – an adapter chuck for different cutter diameters), fix the shaft, tighten it with an open-end wrench until it stops (but do not overtighten).

If the model is simple, two keys are needed. They do not provide a mechanism for blocking the shaft, the second key will need to hold it. Middle-class devices have a lock button. Clamping it, tighten the cutter with an open-end wrench. In expensive models, in addition to blocking, there is a ratchet by which you can navigate.

Setting the milling depth

Each model of a manual router has a certain overhang – this is the maximum depth to which this unit is able to process the material. The maximum depth of milling is not always required, then its adjustment is required. Even if it is necessary to mill to a great depth, so as not to overload the cutter and the unit too much, it can be divided into several levels. There is a revolver for this. This is a small disk under the bar with a number of stops of different heights – legs. The number of legs is from three to seven, and more does not mean better. It is much more convenient if it is possible to adjust the height of each leg. This shows the class of the equipment. To fix the turret in the desired position, there is a latch, usually made in the form of a flag.

Setting the milling depth on a manual router takes place in several stages:

- The tool is placed on a flat surface, the clamps are released, the hand is pressed so that the cutter rests on the surface.

- The turret stop is released by unscrewing its lock.

- Depending on what depth of milling is needed, choose the leg of the turret stop. The disc with legs is rotated to the desired position.

- The screw is not fixed, but the bar is held with a finger, the movable pointer is moved so that it coincides with zero (in the photo above).

- The bar is raised to the milling depth mark, after which the turret lock is lowered (pictured below).

Now, when installed on the workpiece and pressing on the upper part, the cutter will enter the part at the set distance.

On good routers there is a wheel for fine adjustment of the depth of milling. It allows you to adjust the depth without knocking down the settings (you do not need to repeat the entire operation), albeit within small limits (in the photo above this is a green wheel).

Milling cutters for manual router

Milling cutters are cutting tools that process and shape the surface. They consist of a cylindrical part, which is clamped by collets in the unit holder, and a cutting part. The cylindrical part can be of different diameters. Choose one that has a collet for which your machine has. The shape and location of the blades of the cutting part determines the look that the wood receives after processing. Some cutters (for edges) have a thrust roller. It sets the distance from the cutting surface to the workpiece.

Make cutters from different metals and alloys. For processing soft wood – pine, spruce, etc. – use conventional nozzles (HSS), for hard rocks – oak, beech and others – from hard alloys (HM).

Each cutter has a certain resource and maximum speed, which ensures normal operation with minimal runout. Do not exceed the recommended speed – this can cause damage to the router. It also makes no sense to sharpen the cutter if it is dull. They do this on special equipment (worth about $ 1000), where you can set the required sharpening angle. Nothing good can be done manually. So blunt ones are easier (and cheaper) to replace, since they cost relatively little.

Popular species

There are a number of types of router bits that are most commonly used.

- Edge. Serve for processing of lateral surfaces of preparations. With their help, you can make smooth or curly edges, you can form notches and spikes for joining parts. It is this type of cutter that comes with a bearing at the end – it rests on the part, setting the distance from the edge of the workpiece to the cutter.

Some types of edge cutters - Slotted. Serve for the formation of grooves and recesses of various shapes. They happen:

- spiral (a) – mainly used to form technical grooves, for example, a tenon / groove connection;

- fillet (b, d) – for decorating the surface with grooves of various shapes, they can be rounded, V-shaped or curly;

- dovetail (c, d) – to form a groove in the form of a trapezoid, this groove is used for open and hidden connection of parts;

- shaped (d) – with their help, they decorate the surface with grooves of complex shapes.

Groove cutters – for forming recesses anywhere in the part

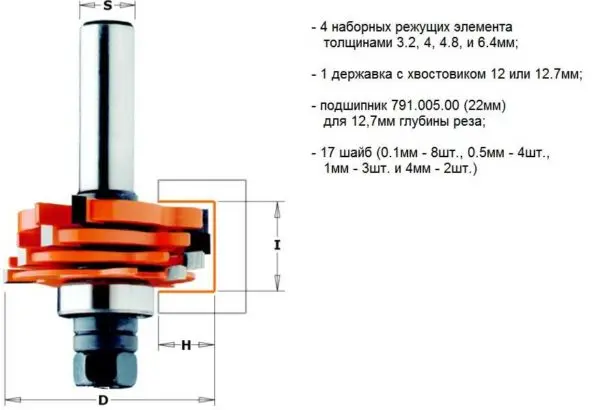

There are simple milling cutters, formed from a single piece of metal, there are typesetting. Type-setting have a shank – a base, a certain set of different cutting planes, a set of washers of different thicknesses. From these details, you can independently form the required relief.

These are the most popular types of cutters, but in fact there are a lot of them. In addition to different diameters of shanks, there are different diameters of cutting surfaces, their height, the location of knives relative to each other, etc. In general, do-it-yourself milling usually requires about five of the most common milling cutters. They are usually present all the time, and the rest are purchased for specific types of work.

Principles of work with a manual milling cutter

An electric milling cutter is a rather dangerous thing – sharp cutting parts rotating at high speed can cause serious injuries, and chips flying from under the tool too. And although most models have a protective shield that reflects the main flow of chips, goggles will not interfere. So the work of a manual wood router requires attention and concentration.

General requirements

Work with a manual wood router will be easier and more enjoyable, the products will turn out to be of normal quality if certain conditions are met:

- The cutter must be sharp. It is difficult to evaluate this parameter “by eye”, therefore it is necessary to focus on working moments: if the motor is very hot and / or the treated surface is not smooth (they say “dirty”), then the cutter is dull. It needs to be replaced.

- The workpiece to be processed must be firmly and securely fastened. You will not get anything good on a jumping and twitching workpiece.

Workpieces must be firmly fixed. Best to use clamps - Small depth of removal in one pass. The more wood you remove in one pass, the greater the load on the cutter. This leads to a decrease in the rotation speed, which increases the load more. Further – in a circle. Therefore, if a large depth of processing is needed, it is better to break it into several passes.

- When replacing the cutter, the unit must be de-energized. And not with a switch, but unplug the cord from the outlet. This will eliminate the possibility of involuntary activation.

Not such complex requirements, but their implementation is the key to good work and safety. Well, the main requirement is that the milling cutter must be driven smoothly, without jerks, shocks. If a strong beating is felt, change the speed. Most often, it needs to be reduced, but in general it is worth focusing on the manufacturer’s recommendations (available on the package).

Edge processing – working with a template

Processing the edge of an ordinary board is easier and faster to carry out on a thicknesser, but if it is not there, a manual milling cutter will also cope, but it will only take more time. There are two ways: without a template and with a template. If this is the first experience with a router, it is better to use a template. When processing the edges of boards, straight edge cutters are needed, and, most likely, two will be needed – with a bearing at the beginning and at the end of the cutting part (pictured).

As a template, you can use an already processed board or, for example, a building rule. The length of the template should be slightly longer than the length of the workpiece – by 5-6 cutter radii on each side. This will make it possible to avoid the “dive” of the cutter into the material at the beginning and at the end. One important point: the horizontal plane (perpendicular to the workpiece) must be flat. In any case, its curvature should not be greater than the gap between the bearing and the cutting part, otherwise the cutter will touch the template, and this is very bad – it becomes imperfect and the resulting irregularities will appear on other copies.

If the width of the part is not more than the length of the cutting edge

The cutting part of the cutters has different lengths, but the larger the cutting part, the more difficult it is to work – more effort has to be applied to hold the unit. Therefore, it is easier to start with a medium cutter. The order of processing the edge with a router (with a template) is as follows:

- Set the template so that it sets the required flat surface – stepping back the desired distance from the edge.

- The blank with the template is securely attached to the table or any other horizontal surface.

- Install a cutter with a roller in the middle part. It is set so that the roller rolls along the template, and the cutting part along the part. To do this, the cutter is installed on a fixed workpiece with a template, a milling cutter disconnected from the network is placed, the position of the nozzle is corrected, and it is clamped.

- Set the cutter in the working position – lower the body, clamp it.

- Turn on a manual milling cutter, guide it according to the template. The speed of movement is determined by the depth of processing. You will feel everything yourself.

- And how to conduct a milling cutter? Pull or push? Depends on which side you’re on. If the workpiece is on the left, push; if on the right, pull. You can also navigate by the overhang of the chips – it should fly forward.

On this, in fact, everything. After you have completed the passage, evaluate the result, remove the clamps.

This, by the way, is another way to remove a quarter along the edge of the workpiece or in some part of it. To remove a quarter, set the cutting part so that the processing is of a given depth.

By changing the cutter to a curly (fillet) and shifting the template or using the stop that comes with the kit, you can apply a longitudinal pattern to the workpiece (pictured below).

In general, this milling technique is quite convenient. For the first steps in woodworking, this is the best way to “fill your hand”, then it will be possible to level the edges even without guides.

The width is greater than the length of the cutting part

What to do if the thickness of the workpiece is not more than the length of the cutting part of the cutter? In this case, the work with a manual wood router continues:

- Remove the template, go through the same cutter again. Only in this case, the already machined part of the workpiece will be the template – the bearing will roll along the newly milled part. You rearrange the cutter so that you can process as much as possible. The holder’s overhang will not let you move much, but some part will still be able to be processed.

- After that, take another nozzle – with a bearing at the end, turn the workpiece over so that the processed part is on the bottom. Fasten to the table with clamps. Install the nozzle with the lower roller so that the bearing rolls over the machined part. Thus, you completely copy the already processed part.

The bearing rolls over the machined part, the cutting part levels the rest

Now the edge is completely processed on one side. If necessary, repeat with the other side. In general, in order to master the work of a manual wood router, you will need several “rough” blanks. Choose from those that you don’t mind throwing away – at first there will be a lot of jambs, then gradually learn.

Obtaining curly and curved edges

If you need not even, but rounded or any other shape of the edge, you need to look at the state of the existing edge. If the workpiece is more or less even, take the necessary edge cutter, install it and process the surface, as described above. If the surface is too curved, it is first brought to a normal state, and then milled.

This is necessary because the bearing roller rolls over the surface and if there are flaws, they will be copied. Therefore, act consistently – first level, then – give curvature.

If a curved surface is boring at all, a template is cut out. The drawing is applied to plywood with a thickness of 8-12 mm, first it can be cut with an electric jigsaw, so the edge is brought to an ideal state with a milling cutter.

In this case, you will also have to work with a router, but so far without a template. When the surface is perfect, the template is fixed to the workpiece and then the work already described above with a manual wood router. Just one point: if you need to shoot in some places a large amount of material, it is better to do it with a jigsaw, for example. Otherwise, the cutter will quickly become dull.

Video tutorials on working with a manual router

When installing doors, it is necessary to cut the hinges, how to do this with a router – in the next video (there is also a guide on how to make a groove, for example, for installing an extension). How to make a homemade milling machine from laminate samples (you can use plywood) and how to make a spike connection for drawers (a table, for example) – in the next video The work of a manual wood router is shown well in the following video, but it is in English. Even if you do not know English, take the time to look. Many operations will become clearer.