Contents

The installation of gas equipment solves two problems at once: to heat the room and provide hot water. But what if there are problems with the equipment? Why does the gas boiler go out? It is unpleasant when this happens at the height of the heating season. You can slowly freeze, or you can study our recommendations and try to fix the problem on your own.

Why does the boiler go out

The reasons for extinguishing the burner or igniter can be both internal and external. Such malfunctions do not depend on the brand of production. Any models “Lemax”, “Conord”, “Proterm”, “Siberia” may be subject to them.

Problems differ in different models depending on the combustion chamber – closed and open type. Let us consider in more detail the causes of breakdowns and their solutions. First you need to know that the burner goes out when the protective automation is triggered. If the system fails, one of the sensors is triggered – the device turns off.

- No draft in the chimney.

- Low gas pressure.

- Extinguishing due to external factors (gust of wind, reverse thrust).

These problems are typical for the models “Danko”, “Aton”, “Ross”.

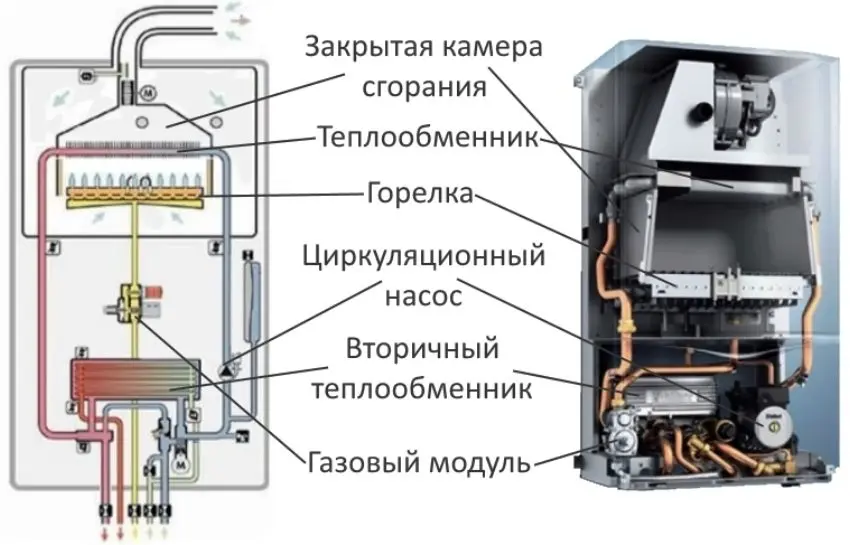

Wall and floor boilers of electrogas type are equipped with a large number of sensors. Therefore, protection works in such situations:

- Stopping the circulation of the coolant.

- Reduced or stopped air supply.

- Voltage fluctuations in the network.

There are parapet-type devices that stop work for these reasons.

Problems of open-type atmospheric boilers

If your machine has been working properly for several years, and now the burner lights up and goes out, look for a problem among the indicated causes.

Traction problems

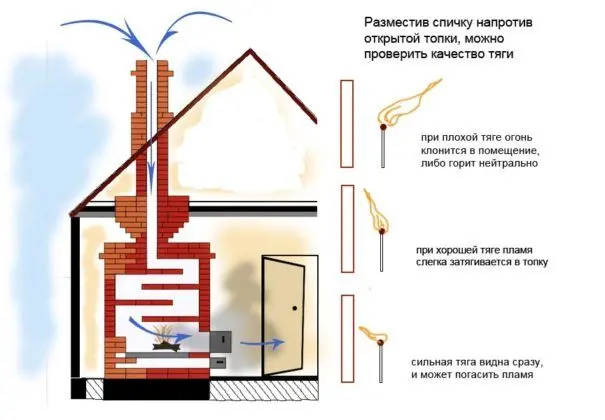

To check its presence or absence, light a match and bring it to the control window. In the presence of traction, the fire will deviate to the side; in the absence of it, it will burn evenly.

What leads to a violation of traction:

- Weather. Wind, rain, atmospheric pressure affect the operation of the chimney. Foreign objects entering the shaft can lead to backdraft and carbon monoxide poisoning. It is necessary to clean the passage, install a check valve that will protect the system from such situations.

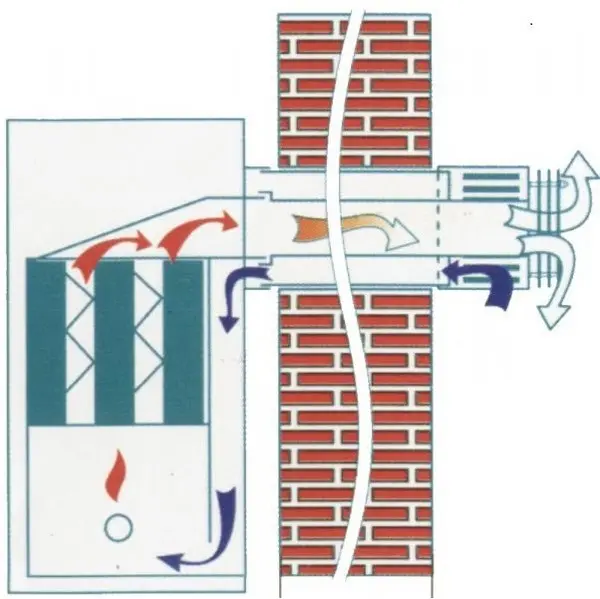

- No proper ventilation. Natural ventilation is required to maintain the flame in an open chamber. The air intake comes from the room. Therefore, it is important to have a window with a window. Slightly open the window to resume the operation of the equipment.

- Naled. Condensate accumulates on the walls of the mine, after which it freezes. As a result, a layer of ice interferes with normal draft and smoke removal. The accumulated layer is knocked off, and the walls of the shaft are insulated to avoid such cases.

- Soot accumulation. This often happens when a solid fuel and gas boiler is connected at the same time. If you live in an apartment building, it is better to contact the utilities.

- Pipe burnt out. Only a complete replacement will help.

As a result of the development of neighboring sites, a tall building can overlap your house, and the chimney falls into the leeward zone. Therefore, the recommended height of the shaft is from 2 meters above the roof.

Head freezing

The head is the part of the boiler that is outside. In case of severe frost, the ice freezes inside and outside, then it cannot be knocked down. Therefore, the head is removed and defrosted. In this state, the device can be started, but first the unit must be warmed up. To do this, turn on the gas valve, then, gradually unscrewing, light the burner. Gradually increase the feed until the structure warms up.

Low gas pressure

If the burner constantly flashes and goes out, then the gas supply is unstable in the system. Wait for the pressure to recover.

Other reasons why the flame goes out:

- Gas leakage at joints. If you smell an odor, close the shut-off valve and contact the repair service.

- Clean the gas filter of the Mimax, Keber or any other boiler, try to light the burner again.

- Poor ventilation is the reason why the wick went out. How to adjust the air supply? Open a window or window, install a ventilation valve.

- Blockage or malfunction of the meter. After repair, the pipeline may become clogged inside the meter. In the event of a breakdown, you can hear crackling, noise, on the screen the numbers jump in jerks.

Independent work with the counter is strictly prohibited. Call the gasmen.

Air supply problems

Did the wick go out after switching on? If this happens frequently, check if there is enough air in the system. As we wrote above, an open chamber will not function without proper ventilation. Open the window and look at the flame in the burner. If it has stabilized, then there is not enough air under normal conditions.

Why does this happen:

- Newly installed plastic windows. The bags are sealed and do not allow air to pass through, so it is recommended to install a ventilation valve.

- You have replaced the door to the room. According to the norms, the gap between the lower part of the door and the floor must be at least 5 cm. When completely closed, the air flow stops.

- Simultaneously with the boiler, a powerful (forced) hood is turned on, which pulls the flow. Turn off the hood while the heating equipment is in operation.

In strong winds, parapet boilers suffer. Some of them are hung on the wall of the house from the outside, thus removing the products of combustion. If gusts of wind blow into one of the grilles of the device, then reverse thrust may occur. To solve the problem, identify the windward side and close the grating on that side.

Closed type turbocharged problems

If you have installed a new chimney-free appliance, but the hearth periodically goes out in it, it is worth checking the components and parts. The problem can be identified by the following signs:

- When igniting the igniter, it periodically goes out. This indicates a thermocouple failure that is affecting the gas valve response. The thermocouple is made in the form of a copper tube. At the end is a bimetallic piece. When different metals come into contact, a voltage of 20-50 MW builds up, which keeps the gas valve open. If the thermocouple breaks down, it cannot be repaired, it needs to be replaced.

- Outdoor unit “Hephaestus”, “AOGV”, etc. does not ignite at all. Check the automation and wiring from the draft sensor to the automatic unit.

- Ignition occurs with pops, a yellow flame breaks out – this is a blockage of the jets. They can get clogged with soot, dust, dirt. You can clean them yourself if you understand gas equipment.

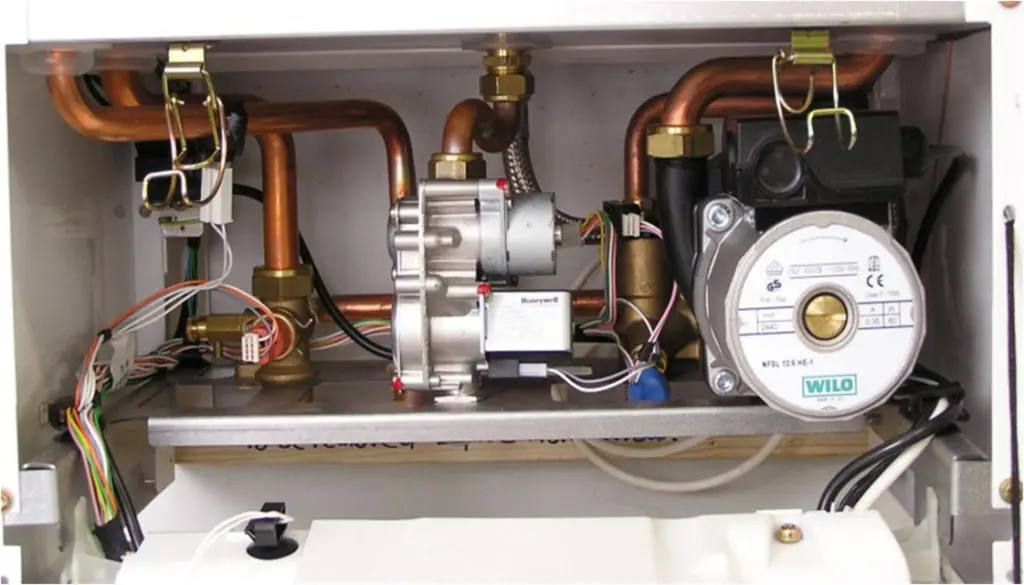

- Malfunction of the circulation pump. In this case, the fire will go out, or ignition will not happen at all. The unit is diagnosed and replaced.

- Broken or clogged thrust sensor. This flat element is connected to the fuel valve. Close the leading contacts and light the burner. If a fire occurs, then the sensor needs to be replaced. During oxidation, the contacts are cleaned with fine sandpaper.

Malfunctions of electrogas equipment

If the equipment is additionally connected to the network, check for voltage. Reverse the plug in the outlet to reverse the phase.

What are the signs of a breakdown:

- The unit does not work, the indicators do not light up.

- The LEDs light up, the display works, but there is no ignition.

- The burner goes out after ignition.

Examine the safety block. Found a burnt part? Install a new fuse – it’s often glued to the front panel. If the steps did not help, then:

- Clean the heating system filter. To do this, turn off the product, close the valves and rinse the filter under running water.

- To remove an air pocket or excess water in the pump, unscrew the main screw in the center. Bleed the air, turn the pump rotor with a screwdriver. When the water drains, return all parts to their place.

- Problems with low pressure in the system can be corrected by pumping air into the expansion tank. The product is located in the inner part of the structure. As a result, the pressure should be less than 0,2 bar than in the general system.

If the burner goes out due to minor problems, you can deal with them thanks to our recommendations. It is better to entrust the replacement and repair of the main components to the repairman. Gas boilers are a high-risk technique, so follow the safety rules.