Contents

Polypropylene pipes are considered by many to be the best. They really have very good technical and operational characteristics: they do not corrode, do not interact with water, do not change its composition and taste, they have a long service life – up to 50 years, they have very smooth walls on which precipitation does not form. In general, there are a lot of advantages. It remains to decide which polypropylene pipes are better, and this is not at all easy. You will have to understand some of the subtleties.

What are and what are better

By structure, polypropylene pipes are of three types:

- Single layer. The walls are completely made of polypropylene.

- Three-layer:

- reinforced with fiberglass – fiberglass threads are soldered between two layers of polypropylene;

- reinforced with foil – the design is similar.

Now briefly about why polypropylene pipes are reinforced. The fact is that this material has a high coefficient of thermal expansion. One meter of a single-layer pipe when heated to 100 ° C becomes 15 mm longer. This is a lot, although no one will heat them that much, but even at lower temperature deltas, the increase in length is no less impressive. To neutralize this phenomenon, compensation loops are installed, but this approach does not always save.

Manufacturers found another solution – they began to make multilayer pipes. Between two layers of pure propylene, they lay fiberglass or aluminum foil. These materials are not needed for reinforcement or any other purpose, but only to reduce thermal elongation. If there is a fiberglass layer, the thermal expansion is 4-5 times less, and with a foil layer – 2 times. Compensation loops are still needed, but they are installed less frequently.

Why make reinforcement with fiberglass or foil? It’s about the operating temperature range. Those with fiberglass can withstand temperatures up to 90°C. This is sufficient for domestic hot water, but not always enough for heating. Foil-reinforced polypropylene pipes have a wider temperature range – they withstand heating of the medium up to +95 ° C. This is already enough for most heating systems (except for those in which there are solid fuel boilers).

Advantages and disadvantages

- Pipes reinforced with fiberglass are more durable. With aluminum foil, pressure and temperature surges are poorly tolerated. The reason is the seam holding the aluminum foil together.

- The glass fiber layer prevents oxygen from penetrating to the coolant, which has a positive effect on the durability of the boiler, preventing the formation of rust. Aluminum is permeable to oxygen.

- The fiberglass interlayer is reliable and does not require frequent maintenance. The quality of pipes reinforced with aluminum film depends on the correct installation.

- Fiberglass systems have reduced heat loss compared to reinforced aluminum, which is good in some cases and bad in others.

- The temperature of use of fiberglass systems is lower and they will sag when heated strongly. Aluminum has a higher temperature range.

Which PPR pipes are suitable for different systems

Based on the foregoing, we conclude that foil-reinforced polypropylene pipes are better for heating if the system is expected to operate at a high temperature. For low-temperature heating systems, products reinforced with fiberglass can be used.

Considering that the recommended temperature in heating boilers that does not lead to the appearance of scale is 60 ° C, then if the diameter of the pipes, the size and number of heating radiators are correctly selected for the heating system, the use of products with fiberglass will be preferable.

Any PPR pipes are suitable for cold water supply, but the most rational solution is ordinary single-layer pipes. They cost quite a bit, and the thermal expansion in this case is not so big, one small compensator for plumbing in an average private house is enough, but in an apartment with a small length of the system, they don’t do it at all, or rather they make it “L” -shaped. For laying the DHW system, it is best to take polypropylene pipes with a fiberglass reinforcing layer. Their qualities are optimal here, but can also be used with a foil layer. Please note that the presence of compensators is required.

For laying the DHW system, it is best to take polypropylene pipes with a fiberglass reinforcing layer. Their qualities are optimal here, but can also be used with a foil layer. Please note that the presence of compensators is required.

Which are easier to install

When deciding which polypropylene pipes are better, pay attention to such a parameter as the complexity of installation. All types are connected by welding, and fittings are used for turns, branches, etc. The welding process itself is identical for all types, the difference is that in the presence of aluminum foil pre-treatment is required – it is necessary to remove the foil to the soldering depth.

In general, there are two types of aluminum reinforcement – external and internal. With the outer, the foil layer is close to the outer edge (1–2 mm), with the inner, the reinforcing layer is approximately in the middle. It turns out that it is filled on both sides with an almost identical layer of polypropylene. In this case, the preparation for welding also consists in removing the outer layer of propylene to the entire depth of welding (and the foil too). Only under these conditions can the required strength of the seam be achieved. All this preparation takes a lot of time, but the most unpleasant thing is that in case of an error we get a very unreliable connection. The most dangerous option is when water seeps into the foil. In this case, polypropylene will sooner or later collapse, the connection will flow.

Based on these data, it can be concluded that, if conditions permit, it is better to use single-layer or fiberglass-reinforced polypropylene pipes. Adherents of aluminum reinforcement say that the foil further reduces the amount of air that enters the system through the walls. But the foil is often made perforated and it does not necessarily go in a continuous strip, covering the entire diameter of the pipe. Often it has a longitudinal gap. After all, its task is to reduce the amount of thermal expansion, and even strips of more stable material cope with this task.

Manufacturers of high-quality polypropylene pipes

Having decided on the type of PPR pipe that you need, you need to decide which manufacturer is better. The task is not easy, although there are clear market leaders in quality – the Germans. It is strange, but very often it turns out that German building materials are the best, and polypropylene pipes are no exception – it is German products that lead in terms of quality. Here is a list of firms that have a very good reputation:

- (Beringer). The pipes are made from a random copolymer, so they can be used to supply drinking water.

Polypropylene pipes Banninger (Baringer) have a characteristic green color - Aquatherm (Aquaterm). This campaign is constantly being developed, using the latest materials and technologies. In recent years, pipes of the “green” series have appeared, which are absolutely safe.

- Wefatherm (Vefatherm). Under this brand, a new generation of foil-reinforced pipes is produced. They differ in that they do not need to be cleaned during welding, which greatly speeds up and simplifies the installation of a heating or hot water supply system.

Another German polypropylene pipes Wefatherm (Vefatherm) - Rehau (Rehau). A well-known company with a wide range of products and quality that has been proven over the years.

Here you can’t even say that some products are better, some are worse. All are about the same. The whole question is which of the firms is represented in your city / region. They have only one drawback – more than a decent price. No others have been seen.

Czech polypropylene pipes are no less popular. In terms of quality, they are almost as good as German ones, but have a slightly lower price. There are two main brands on the market:

- FV-Plast (FV-layer). In production, a random copolymer of the third type is mainly used (denoted by PPR, today it is the best so far). The products are suitable for transporting water up to +90 °C and have good flexibility. This allows you to use fewer fittings, which means that the cost of the pipeline will be less in the end (fittings are expensive).

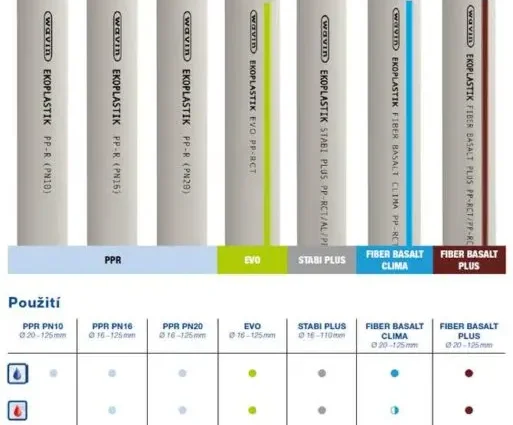

- Wavin Ekoplastik (Wane Ecoplastic). Copolymers with various additives are used. This campaign has its own “trick”, when reinforcing the pipe, the foil is used perforated. This achieves better adhesion of all layers.

Range and purpose of PPR pipes Wavin Ekoplastik

These pipes also have a good reputation and excellent reviews. If you have them in your store, you can take them without hesitation.

Turkish polypropylene pipes are located in the middle price segment. If the concept of “best” also includes a not very high price, then you need to choose the products of these companies:

- Pilsa (Pilsa). Three-layer glass-fibre reinforced pipes are produced. Scope – cold and hot water supply, heating systems.

- TEBO (Tebo). The range includes ordinary polypropylene pipes, also reinforced with fiberglass and foil. Suitable for transporting cold and hot liquids and gases.

- Valtek (Valtek). In production, PPR-100 polypropylene is used, which has increased strength characteristics. There is a complete set – single-layer, multi-layer, reinforced with fiberglass and solid aluminum foil.

- Kalde (Kalde). A third type random copolymer (PPR) is used, which is characterized by increased strength and flexibility. It can be used for heating, hot and cold water supply, sewerage.

- Vesbo (Vesbo). This Turkish company produces single-layer polypropylene pipes for cold and hot water (up to 70 ° C), reinforced with perforated foil, suitable for heating and hot water.

Vesbo products have a good reputation - Firat (Firat). Random class 3 copolymer is used, which has the best characteristics today. Both simple (single-layer) pipes and reinforced (multilayer) pipes are produced.

- Jakko (Jacko). With good quality, the product has an acceptable price. There is a complete set – single-layer, reinforced with fiberglass and aluminum foil.

Almost all Turkish manufacturers of polypropylene pipes operate in the middle price range. The quality of the products is good, the assortment is decent. If funds allow, choose from these manufacturers. If you need even more budget solutions, look towards Russian and Chinese manufacturers:

- Chinese PPR pipes BLUE OCEAN have a good reputation. They can be safely used, problems rarely occur.

- The Russian company PRO AQUA (Pro Aqua) produces sanitary wares from class 3 random copolymer (PPR). Two types of pipes are produced – single-layer and reinforced with foil (solid reinforcement, butt-stitching foil).

- The Orenburg company RVC makes polypropylene pipes in a full range – both ordinary and reinforced. At a low price, they have normal quality. Not German, of course, but for the money – not bad.

- Heisskraft (Hayskraft). This German company has launched two factories in Russia – in St. Petersburg and Krasnodar. The quality of the products is high – the Germans make high demands, and the prices are much lower than the pure “Germans”.

- The Russian company Politek (located in the Moscow region) produces polypropylene for cold water supply (from PPR-80), as well as sewer polypropylene pipes for external and internal wiring.

The products of all these brands have been on the market for many years, the firms have a stable reputation. However, periodically there are reports that some products were of very poor quality. When they begin to understand, it turns out that a fake was bought. By the way, the number of fakes can be used to measure the popularity of a particular brand: many fakes are a very popular product. How not to make a mistake when buying – read on.

How not to be mistaken

If you have chosen better polypropylene pipes for yourself, before buying, go to the official website of the manufacturer. You will need:

- Remember what the logo looks like, what font is used, what letters it has, what color they are written in, how many capital letters. In general, you need to study the logo and its spelling. Those who make fakes deliberately make some kind of mistake in the name, change / omit / double some letter. This is done so that it is impossible to make claims – the letter is different, another brand.

- Next, you need to study the range, choose what you want to purchase. Then carefully study the color, the location of the markings. If the store offers you a product of the desired campaign of a different color, size, etc., but this is not on the official website, then you are being sold a fake. Better to leave and look for another store.

All walls must be perfect - Please review product samples before purchasing. Pipes, fittings of normal firms have even walls (both external and internal). There should not be any sagging, depressions or other signs of poor-quality casting.

- Look at the cut of the pipe or fitting. The wall thickness must be the same. If these are reinforced products, then the reinforcing material is surrounded by polypropylene rings of the same thickness. If the difference is noticeable even “by eye”, you should not take such products.

In general, you should have a positive impression of the quality of the products. Only if all the “tests” are passed, you can buy.