Contents

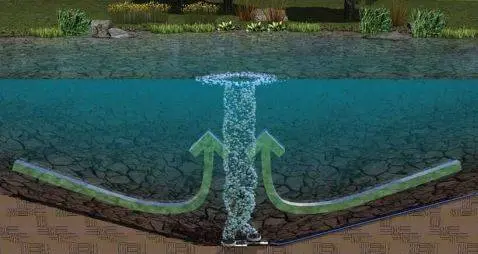

Vortex blowers are unique equipment that can act as a compressor and a vacuum pump. The task of this machine is to move the flow of air or another gas, liquid in a vacuum or low pressure. The equipment is used in many industries. Vortex blowers of various types and models are installed in vacuum cleaners, vacuum lifters, pneumatic transport, medical equipment. In everyday life, blowers can be used to aerate ponds, clean ventilation and sewer systems, and pump compressed gas. If necessary, you can purchase a ready-made model of such equipment or order a blower with the necessary characteristics from the manufacturer.

Functional differences of the blower

Both in industry and in everyday life, various types of compressors or fans are more often used. The vortex blower is less common compared to these types of equipment, despite the fact that its functionality is wider. Its main differences from common machines are:

- A vortex blower creates a much higher pressure than a fan, but has a lower performance.

- Compared to a compressor, a blower creates less pressure, but is characterized by greater performance.

In addition to the technical characteristics of performance and the pressure created, vortex blowers differ from other equipment in the principle of creating an air flow. The thing is that the blower does not just pump air, but creates the very vortex in which gas molecules move “not in volume”, resulting in a vacuum.

Advantages and disadvantages of equipment

In some types of work, the vortex blower can technically be replaced with another type of alternative equipment. However, blowers are more often preferred in the industry because they have some comparative advantages:

- The vortex equipment is lightweight, which makes it easy to move and install easily.

- In operation, such installations create a low noise level.

- Vibration during operation of the blower is completely absent.

- When moving gases, there is no pulsation.

- The equipment is compact.

- The cost of a vortex blower is lower than the cost of a vacuum pump.

- Vortex blowers are characterized by low energy consumption.

- The equipment has a simple design with a small number of rubbing parts, due to which it rarely breaks and has a high level of maintainability.

- The absence of rubbing parts does not require the use of lubrication, and allows you to get clean air at the outlet. It is this advantage that makes the equipment affordable for the food industry and medicine.

Vortex blowers, in addition to their advantages, also have a number of disadvantages:

- Design features do not allow to obtain high efficiency in the operation of the vortex machine. Manufacturers are trying to eliminate this drawback in the manufacture of modern models of equipment. One of the technologies for increasing efficiency is the introduction of side channels into the design of the blower.

- The need to install an air filter. In the absence of a filter, there is a high probability of small objects getting into the gap between the blower housing and its impeller. Even a small object in the “body” of the equipment can disable it.

- Vortex blowers are able to heat the air at the outlet up to 700C. In this case, the safety valve saves the machine from overheating, the performance of which must be regularly monitored.

Thus, the blower has its advantages and disadvantages, comparative features that must be considered when buying a particular model. In turn, conscientious manufacturers seek to eliminate many shortcomings by constructively modernizing the models they produce. That is why it is recommended to familiarize yourself with the new products on the market before buying a vortex installation.

Working principle of rotary blower

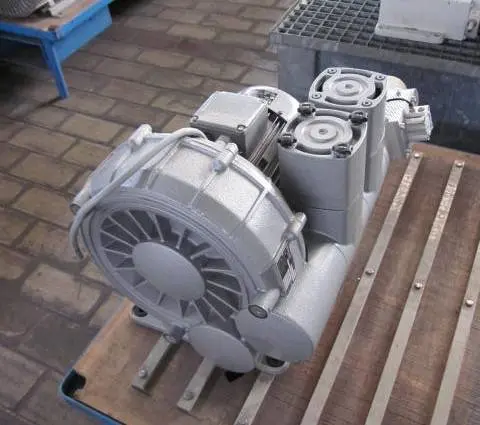

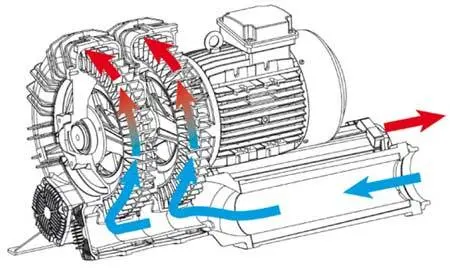

Most models have a very simple design, in which the working body is directly located on the motor shaft. The power and productivity of the blower depends on the speed of rotation of the shaft. There are many radial blades on the impeller along its circumference. An important point is the geometry of their location (angle of inclination, size), on which the performance of the installation depends. The impeller is inside a metal casing. The metal frame has an internal and external channel through which the gas flow moves:

- From the inlet, the wheel blades suck in air.

- When the impeller rotates, air moves between the blades and is pushed forward by centrifugal force.

- With constant rotation of the wheel, the pressure increases to a maximum value.

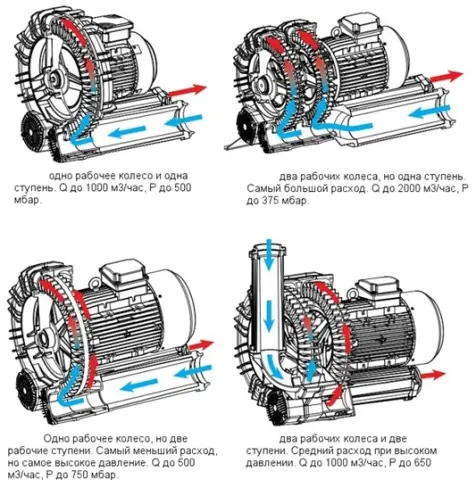

The design of the blower may include one or two impellers. Such installations, depending on the air rotation cycle, can be single-stage or two-stage. Two-stage units are more often used in industry for pumping more pressure.

The working principle of multi-stage vortex blower is similar to that of single-stage simple machine. The only difference is that the gas, after passing around the circumference of the first impeller, is not pushed out, but is picked up by the blades of the second impeller. You can see a diagram of such equipment below in the picture:

Industrial rotary blowers

Swirl-fed equipment can generate pressures between 300 and 750 mbar in continuous operation. This is indicative primarily depends on the design of the equipment. So, 4 different blower schemes can be distinguished:

It is worth paying attention to the fact that mechanisms of the same design may differ in some indicators due to the features of a particular model.

The design of the blower may include an open or closed arrangement of the blades. Installations with closed placement of blades have one significant advantage: they can work not only with gas, but also with dusty substances and liquids.

Interesting to know! Many companies use pneumatic mail to transfer papers, the work of which is based on the use of vortex equipment. Such complex vacuum channels, for example, are installed in many supermarkets to transfer banknotes from the cashier to the accounting department.

Using a blower at home

In domestic conditions, a vortex blower is rarely seen. As a rule, it is replaced by a compressor or a fan. Such a low level of prevalence among the general population is observed due to ignorance of all the possibilities of this device. For example, the blower can be widely used in the garage, for inflating wheels, operating a wrench and other pneumatic equipment. The swirling air flow can quickly dry, clean or paint the surface. You can also use the equipment as a pump for water supply.

You can see the operation of vortex equipment in everyday life on the video:

On the video, an experienced user will talk about some of the characteristics of the device and demonstrate its performance.

Models from the manufacturer

In the market for specialized equipment, you can find many different models of vortex blowers. They may differ in their design, technical characteristics and, of course, cost. At the same time, it is important to understand that the device of the mechanism from different manufacturers is approximately the same and quite simple, so it makes no sense to overpay for the brand in this case.

To get an idea of manufacturers and prices, you can compare several models of vortex equipment. So, a unit manufactured in the Federation, creating a pressure of 125 mbar and a vortex flow velocity of 80 m3/h will cost 15 thousand rubles. A similar German-made installation will cost the buyer 19 thousand rubles. Agree, the difference in price is considerable, given that the equipment of two different brands has exactly the same characteristics.

For domestic use, for sure, everyone will be able to choose the right model for themselves. At the same time, for industrial enterprises, manufacturers can custom-make equipment with the necessary design features. Such cooperation is possible both with and foreign manufacturers.

Whirlpool blowers are widely known in industry and rarely used in everyday life. However, the scope of their application in the economy is very, very wide. With their help, you can speed up the work of repairing a car, saturate a heavily stocked pond with oxygen, and aerate the water in the pool. You can use such installations as a vacuum cleaner or a pump for water supply. Having an airbrush at hand with the help of a stream of air, you can quickly and efficiently paint any surface. Thus, in everyday life, a blower can perform a whole range of functions, replacing compresses, a fan and a pump. The cost of such universal equipment is quite affordable. The manufacturer, in turn, guarantees high quality workmanship and long-term warranty service.