There are no trifles in this business, each detail is important in its own way and affects the final taste. Most manufacturers have secrets regarding cleaning and filtration, but in general, the technology for the production of vodka is the same for everyone. We will look at the main stages that our national drink goes through before getting on sale.

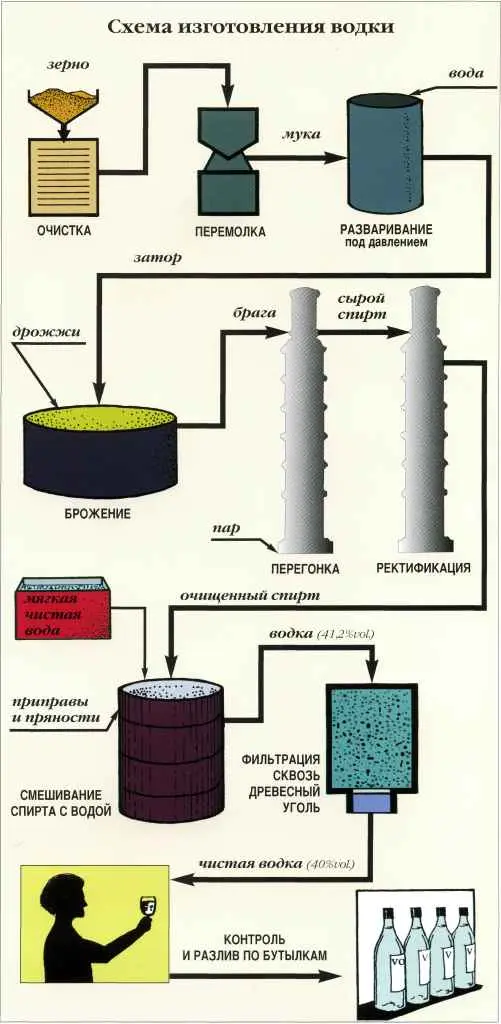

Many people think that there is no difference between store-bought vodka and moonshine. Actually it is not. Moonshine is made by distillation (distillation through a moonshine still), and vodka is a product of rectification (thermal purification) of alcohol. With full observance of the production technology, vodka is much better cleaned of third-party impurities than moonshine. The classic scheme for making vodka is shown in the figure.

Stages of vodka production

1. Water preparation. First, technologists adjust the salt composition, the salt content should be minimal. Then the water is purified by sedimentation, aeration and filtration through carbon filters and (or) quartz sand. At some enterprises, additional molecular and ultraviolet purification is used. Water must not be boiled or distilled, otherwise the vodka will become hard and lose its unique taste.

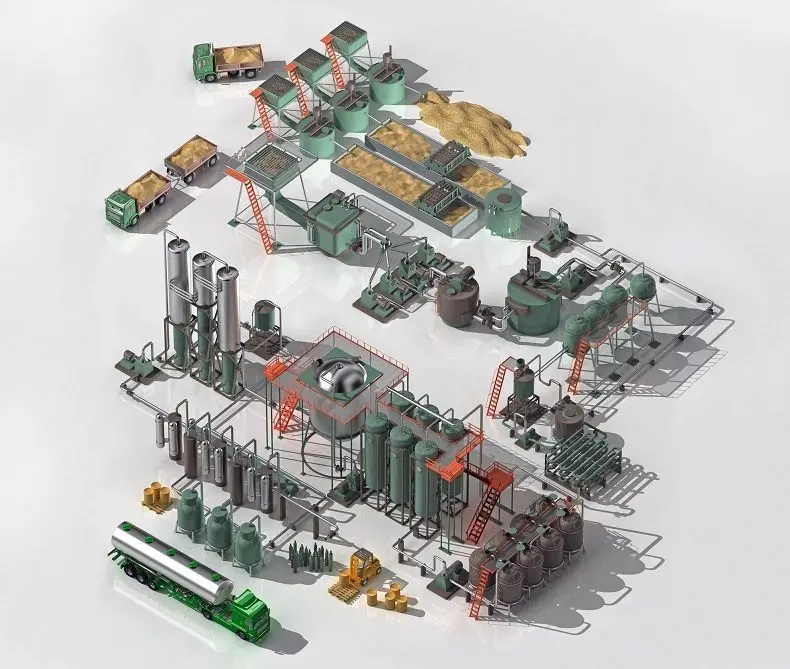

2. Obtaining and purification of alcohol. The main raw material for the production of vodka alcohol is wheat. A small amount of barley, corn, millet, peas or other food starchy raw materials can also be added to the wort.

Cereals are ground into flour, then brewed under pressure in special columns. Next, the wort enters the fermentation vats, where yeast is added. The finished mash is fed into distillation columns to obtain raw alcohol, and then to distillation columns for its purification.

In the production of vodka, it is allowed to use only three classes of ethyl alcohol: “Highest purification”, “Extra” and “Lux”. Many companies have their own facilities for producing alcohol, others order it directly from distilleries, but it is somewhat more difficult to control the quality there.

3. Sorting. This is the process of obtaining a water-alcohol mixture. Alcohol and water in the right proportions are fed into closed sorting vats, where they are mixed with special devices. Then other ingredients are added, if they are provided for in the recipe. For example, to obtain lemon vodka, lemon juice or chemical flavors should be added to replace it.

4.Filtration of the mixture. In most cases, quartz sand is used. A mixture of water and ethyl alcohol comes from the tank to a special cleaning filter, after which it flows into the next vat. As sediment accumulates, it begins to interfere with normal filtration. After some time, quartz filters need to be cleaned. This moment is determined by the height of the sediment layer.

5. Purification from harmful impurities. At this stage, the organoleptic characteristics of vodka are formed. Carbon filters clean the drink from aldehydes and esters. Depending on the desired quality of the finished product, activated carbon filtration can be carried out several times.

6. Assimilation. The process of settling the finished alcohol-water mixture. According to the standards, assimilation should last at least 2 days. But experienced technologists say that this is too short a time, and in many distilleries, settling lasts up to 7 days.

7. Bottling. Each bottle is checked for integrity, then rinsed with water. Special automatic lines are used for filling. First, vodka is poured into a bottle, which is then sealed with a special cork. The final step is labeling.