Contents

Comparative analysis of three selection schemes that are used in domestic mash and distillation columns. Characteristics, advantages and disadvantages, as well as applicability in various distillation options are considered. Each method has its own type of equipment.

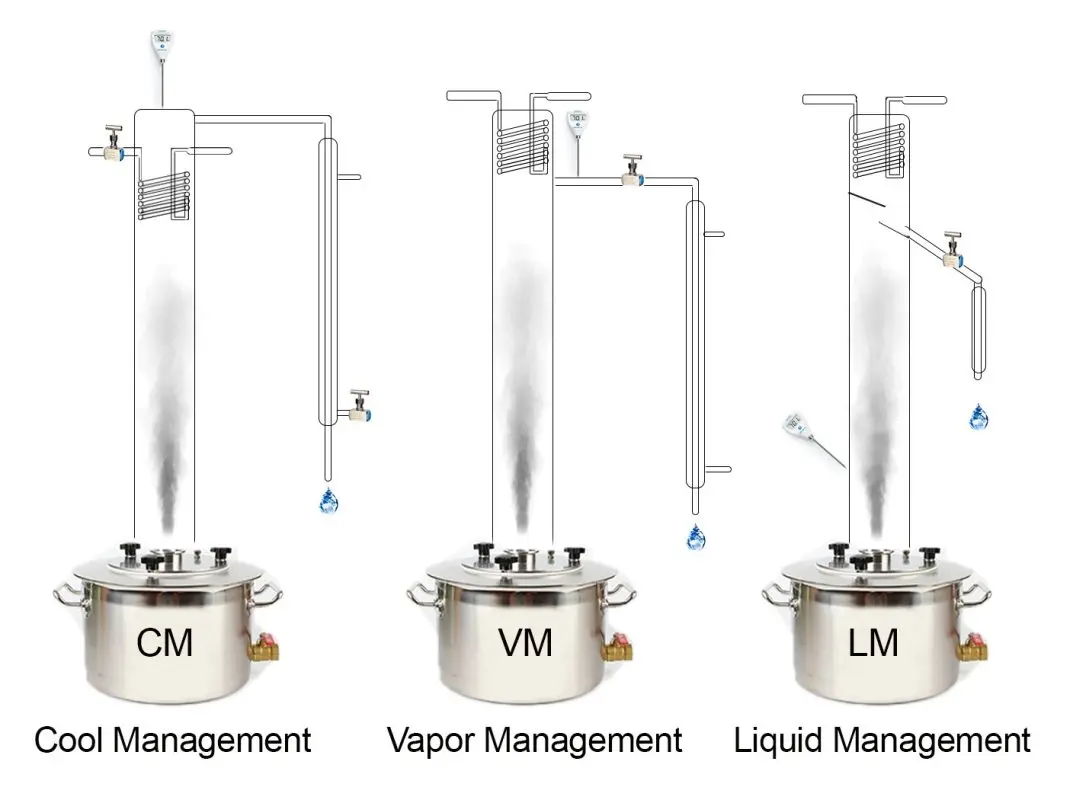

To successfully work with the column, you need to adjust the reflux ratio. There are three methods for this:

- CM (cool management) – control of the flow of water supplied to cool the dephlegmator;

- LM (liquid management) – control of the amount of reflux taken (liquid selection);

- VM (vapor management) – management of the amount of vapor taken (selection by vapor).

Before starting a conversation about the types of selection, let’s define the terms.

Distillation – the process of evaporation of a liquid with subsequent condensation.

If initially the raw material was evaporated from the distillation cube, then condensed in a refrigerator (condenser), then whatever happens in the middle of this process (passage of steam through a dry steamer, bubbler or reflux condenser), eventually distillate will still be obtained.

Rectification – this is one of the distillation methods, which is distinguished by two technological methods:

Forced, strictly regulated return of reflux with the help of special devices – dephlegmators or condensers.

Organized heat and mass transfer between the phlegm and rising towards the steam. To increase the efficiency of heat and mass transfer, packing or tray columns are used, where reflux is reevaporated. In the first case, the process has a film character, in the second case, it is bubbling.

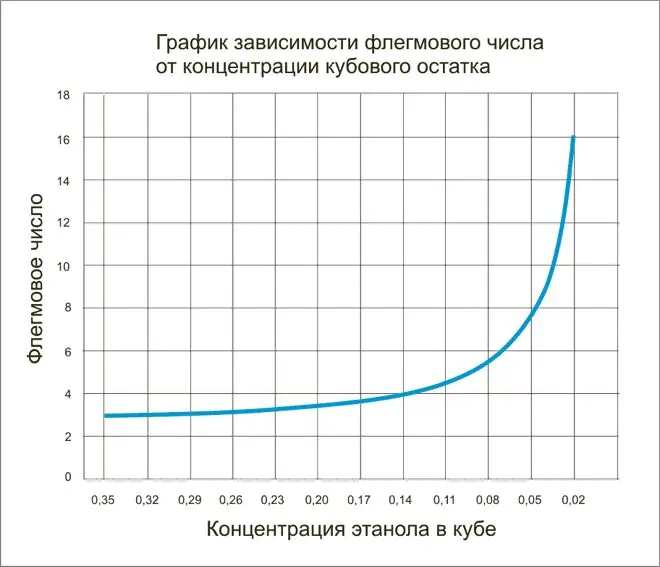

The purpose of rectification is to obtain alcohol of a given strength and its purification from impurities. For this, the reflux number must always be above the minimum (for more details, see the graph).

The quality of the product depends on the value of the reflux ratio, but the higher it is, the lower the performance of the column.

Rectification does not allow to isolate any mixture from the group, but only more or less completely removes all impurities grouped by close volatility. Therefore, if distillation equipment is used to obtain, for example, fruit distillates, there is a risk of grouping the head fraction into difficult-to-separate azeotropes – removing useful esters responsible for aroma along with unnecessary impurities.

If you try to drive out a noble distillate on distillation equipment, it is necessary that during the entire selection the phlegm number does not exceed 1,5-2. Otherwise, the balance of impurities will be disturbed.

Types of selection nodes in the column

Liquid selection (liquid management)

LM – adjustment of the amount of selection by liquid. The most convenient and easy-to-operate scheme, in which all vapors are condensed, then one part of the condensate is returned to the column, the other goes to the selection.

Characteristics. Adjustment of the reflux ratio is carried out by one needle valve for the selection of alcohol. If the tap is fully open, the reflux ratio is zero, and the output is ordinary distillate. When the tap is closed, the reflux number is infinitely large – the column works for itself. Adjustment of the liquid selection valve allows you to change the reflux ratio from 0 to 100% at any time. The heating and cooling power is set at the optimum level, providing the maximum separating capacity of the column and minimum reflux cooling.

As a rule, the reflux ratio is set somewhat higher than the minimum, which, when selecting the “body”, allows you to do without adjustments for a relatively long time, but towards the end of the selection, you still have to actively regulate the process. Moreover, the less alcohol remains in the cube, the more often it is necessary to increase the phlegm number.

Advantages:

- suitable for obtaining both aromatic and pure alcohols;

- easily and relatively cheaply automated up to ACS (automated control system) of the production process with safety blocks;

- no increased sensitivity to cooling water pressure stability.

Disadvantages:

- if we fix the selection rate at the same level, then as the rectification proceeds, the phlegm number will decrease. This contradicts the technological need to gradually increase the speed towards the end of the selection, which is the main drawback;

- it is necessary to break the jet (connection with the atmosphere) after the control cock or valve, otherwise there may be failures in the adjustment of the extraction rate due to the rarefaction in the extraction line, which is created by the flowing down flows of alcohol.

Vapor management

VM – regulation by separation of steam flows to a dephlegmator. The column is controlled by changing the amount of extracted steam using a slide or conventional ball valve.

Characteristics. The ratio of the cross-sectional areas of the column and the steam pipe determines the minimum reflux ratio, which can be increased by adjusting the position of the valve.

During distillation, the amount of phlegm returned is controlled from 80 to 100%. The minimum possible reflux number is 4.

Advantages:

- the sensitivity to the position of the tap is very small, which allows you to make precise adjustments;

- the reflux ratio does not depend on changes in temperature or cooling water flow in the dephlegmator;

- no increased sensitivity to cooling water pressure stability.

Disadvantages:

- the control system is inertial, from changing the position of the crane to changing the selection speed, it can take up to 10-15 seconds;

- not suitable for obtaining aromatic spirits from natural raw materials. Requires design changes to adjust the amount of returned phlegm from 50 to 100%;

- the vapor column is sensitive to blockages in the product line. If a column of product forms in the silicone hose, flowing down, it will create a vacuum, and, like a pump, will draw steam towards itself, violating the set reflux ratio. As a result, the extraction rate will increase sharply and uncontrollably; without operator intervention, the system will not return to its previous level. You can stop uncontrolled selection by establishing a connection with the atmosphere (creating a break in the jet). For example, stick the needle from the syringe into the top of the sampling tube;

- automation is complex and expensive. It is often performed in the form of a signaling device for reaching certain temperatures, but without actuators. Security automation is also desirable.

Cooling management

CM – adjustment of the amount of water supplied to the dephlegmator. Allows you to control the amount of steam passing through the reflux condenser to the product take-off cooler.

Characteristics. The reflux ratio is adjustable from 0 to 100%, but the system is very sensitive to the amount of water supplied and requires a precision needle valve. To control the selection speed, you have to turn the valve literally a fraction of a millimeter. The heating power during the entire process must be constant and ensure the maximum separating power of the column. With an increase in the amount of water supplied, the amount of returned phlegm also increases, respectively, the reflux number increases.

During rectification at a constant cooling and heating power, a gradual decrease in selection occurs, but the reflux ratio remains unchanged.

Advantage:

- can be successfully used to obtain aromatic alcohols from natural raw materials.

Disadvantages:

- the slightest fluctuations in pressure lead to a change in the rate of selection and reflux. If measures are not taken to stabilize the pressure of the cooling water in the apartment, even the toilet flushed by the neighbors will affect the selection process;

- an increase in the temperature of the water in the reflux condenser with its constant amount reduces the reflux ratio, therefore, to maintain a stable reflux ratio, it is necessary to control the flow and temperature of the water supplied to the reflux condenser;

- connection with the atmosphere in the product sampling line is required, otherwise, if the heating is accidentally turned off and the tube immersed in the sampling, the entire product will again be in the cube;

- The system is expensive and difficult to automate. Usually, simple thermal alarms and safety automatics are installed on such distillation columns.

The practice of installing different sampling units on columns

Liquid extraction columns (LM)

In domestic columns, liquid selection is most widely used. The reason is simple – the rectification process of 40 liters of moonshine is delayed for 18-20 hours. It is possible to reduce the bulk by half, but then the share of circulating (technical) alcohol, which will have to be processed at each rectification, sharply increases.

If we talk about the performance of the system as the amount of commercial alcohol obtained during the total time of rectification (including heating), then with a 2-fold decrease in bulk volume, the efficiency decreases by about 1,5 times.

Another way to minimize the volume of technical alcohol obtained at maximum productivity is to automate the process, which allows distillation according to a predetermined algorithm without the participation of an operator. The automation system must necessarily have not only an executive circuit, but also a safety unit that will instantly turn off the equipment in the event of an accident.

A distillation column with liquid extraction is easier and cheaper to automate than other systems, and the quality of the resulting alcohol is in no way inferior to other types of equipment.

Steam extraction columns

Steam selection systems are common abroad, where alcohol and its derivatives are inferior in popularity to distillates (cognac, whiskey, etc.), but the high strength of the drink is appreciated. Foreign craftsmen design distillation columns with steam extraction, which have a minimum phlegm number – only 1, and not 4 as in Russia. With this scheme, at least 50% of reflux goes back into the column.

In distillation mode, steam extraction practically does not need automation. The reflux value set at the start of the “body” selection remains unchanged until the end, only the operator can change it, but even when obtaining alcohol, adjustment is needed literally a couple of times.

The rate of selection by the end of the distillation sharply decreases until it stops. If there is a desire to hunt for enanthic esters (in many respects they create the organoleptic properties of fruit distillates), they change the jars and increase the heating power, then fractional selection and sorting follows.

If enanthic esters are not required, do the same, but additionally use pauses to work the column on itself so that the alcohol residues are more concentrated and with fewer impurities.

Automation in columns with steam extraction is needed only at the level of the safety block. In addition, obtaining a distillate does not involve grouping impurities into fractions and their complete removal, but a balanced decrease in the concentrations of substances to an acceptable level with the obligatory preservation of flavoring components. This is a matter for the master distiller who controls the process; instrumentation is inappropriate here. Bulk is limited by the volume that can be overtaken under the guidance of a person in the time available.

Columns with adjustable water supply to the dephlegmator

Despite all the shortcomings, this type of equipment is often used in Russia in the construction of beer columns. The reason is the possibility of obtaining distillates from any raw material, and if necessary, without changing the design (an additional drawer side does not count), you can collect distillate of a high degree of purification – almost like alcohol.

Columns with adjustable water supply to the reflux condenser are expensive in automation, sensitive to the pressure and temperature of the cooling water, which makes them poorly suitable for obtaining pure rectified alcohol, but with small bulks of up to 20 liters and the vigilant attention of the operator, such columns are capable of much.

In addition, the cool management scheme is the best for selecting “heads”. Ceteris paribus, it is impossible to obtain more concentrated “heads” on steam and liquid extraction systems. True, this is only if you manage to stabilize the temperature and pressure of water in the dephlegmator.

In recent years, attempts have been made to create hybrid distillation columns, in which the “heads” are selected by steam by the CM method, and the “body” by liquid (LM). This enhances the already high alcohol quality of the LM columns. There are no boundaries for perfection.

In the construction of beer columns oriented to aromatic distillates, VM equipment has an advantage over SM due to ease of control, as well as insensitivity to temperature and water flow in the dephlegmator – more predictability in the “combing” of impurities. For sugar raw materials, beer columns according to the SM scheme are more promising due to better removal of the head fraction. But managing them creates a lot of problems.

The author of the article is IgorGor.