Contents

The trailer for bees can be purchased in a finished factory-made design. However, there is one significant drawback – the high cost. To transport an apiary, beekeepers often make home-made devices from decommissioned trailers for agricultural equipment or cars.

Benefits of using trailers in beekeeping

The simplest device for the owner of a nomadic apiary is a cart for transporting bees, attached to a car. The vehicle allows the transportation of a small number of houses. The owner of a large nomadic apiary benefits from a spacious platform.

The advantage of using a trailer for transporting hives is explained by the advantages of a nomadic apiary:

- The nomadic method of keeping the apiary contributes to the best development of bees in the middle of spring.

- Moving the hives to another location benefits the bees. Insects get access to the required amount of nectar.

- For a nomadic apiary, the honey collection season starts earlier and ends later. Transportation of bees to flowering honey plants brings the beekeeper more harvest. Buying a trailer and fuel for transport will pay off if you collect 6 kg of quality honey from each hive.

- During the transportation of the apiary, the beekeeper independently chooses which honey plants to stop near. Frequent roaming allows you to get different varieties of honey during the season.

If we talk about the advantage of the towing device itself, then small carts for passenger cars are beneficial in terms of compactness. However, the downside is the capacity. Usually, a standard light trailer transports a maximum of 4 hives with bees at a time.

Large trailers called platforms have many advantages:

- During transport, the shaking on the hive platform is minimal compared to a small trailer. The bees do not get stressed, they behave calmly upon arrival at a new place.

- When transported by a cart, the hive must be unloaded and loaded. On the platform, houses with bees are constantly standing.

- Due to the stability and high sides, the platform transports a large number of hives installed in several tiers.

Having a trailer or platform for a beekeeper is always a big plus. Non-export bees bring little honey. Families weaken, eventually die.

Types of trailers for transporting beehives

There are many varieties of homemade and factory trailers used to transport bees. By design, they are conditionally divided into three groups: carts for passenger cars, platforms and pavilions.

Beekeeping trailer for a car

There is a beekeeper’s car trailer of a specialized design and a home-made version, modified by a beekeeper. In the first case, the towing device is adapted from the factory for the transport of beehives. In the second version, the beekeeper remakes the trailer himself.

The standard model, for example, for a Zhiguli car, holds 4 beehives. You can build up the sides by installing 8 houses in two tiers. If there are a lot of horses under the hood, beekeepers expand the frame, adapt the platform on a retractable mechanism. A good option is a bee trailer for a UAZ car for 25 bee colonies, which allows you to transport an average apiary at a time.

Platforms for transporting bees

In fact, the platform is also a trailer, only more spacious. The design is usually biaxial. When transported in 2 tiers, up to 50 hives can be accommodated. A single-tier apiary is usually not removed from the platform. The hives are in place. There are large platforms that can accommodate more than 50 hives. If desired, the design will be improved with a roof.

Pavilions

There are stationary and mobile pavilions. In the first case, the structure is installed on the foundation. The mobile pavilion is similar to the platform, but is equipped with a roof, walls, and a door. The hives stand with their entrances outside in several tiers, and here they hibernate.

Mobile cassette pavilions are convenient in terms of use. The bees live in special modules that make maintenance easier for the beekeeper.

How to make a do-it-yourself bee trailer

The usual single-axle trailer for transporting bees for a car will be improved by building up the sides. Removable racks with a roof can be adapted. In order to capture more hives in one transportation, the frame will have to be expanded. It is desirable to add a second axle. The entire manufacturing process of the towing device consists of assembling the frame and its skin.

Drawings, tools, materials

They begin to make a trailer for hives by building a drawing. Initially determined with dimensions. When choosing dimensions, it is important to take into account the traction force of the car so that it can handle the load. An example of a finished drawing is easy to find in various sources. You can customize your sizes. It is important to remember that the trailer will have to be driven to the apiary along the highway. Its dimensions should not interfere with the movement of vehicles.

Of the materials used sheet metal, pipe, profile, corner. From the tools they take a grinder, a drill, a welding machine, a hammer, pliers, wrenches.

Assembly process

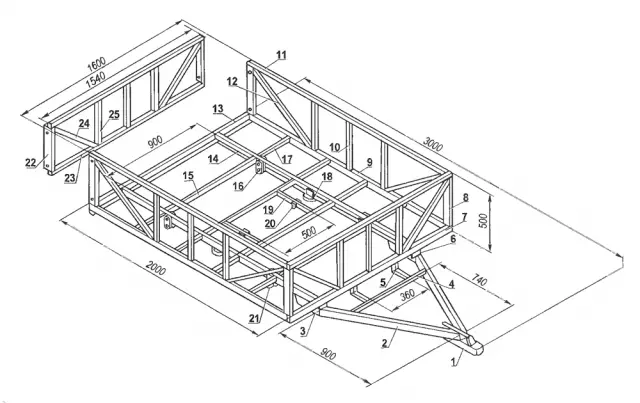

They begin to assemble a trailer for transporting bees with their own hands from the layout of the hives. The place of the houses is marked on the drawing, from here the size of the frame is determined. The further process consists of the following steps:

- According to the drawing, the frame is welded from the profile, corner and pipe. If a factory trailer is being reworked, then the structure is usually expanded, a retractable platform is made. If necessary, add a second wheel pair.

- If it is planned to build a van with a roof, the frame is equipped with racks. The walls are sheathed with plywood. Holes are cut opposite the notches.

- The roofing material of the van is metal, corrugated board.

- When it is supposed to transport beehives in 2 tiers, shelves from a metal corner are welded under the houses to the frame of the trailer.

- For hives, fasteners are provided to hold them during transportation.

When the beekeeping trailer is ready, they try to install empty hives, test the design. If everything goes well, with the beginning of the season, the bees are brought closer to the honey plants.

DIY bee platform

A platform for bees is considered the best option due to the larger capacity of the hives. In addition, the houses remain standing on the trailer after arriving at the parking lot.

Drawings, tools, materials

In the manufacture of the platform, you will need similar tools and materials that were used to assemble the trailer. The drawing differs in size. The platform must be equipped with two wheelsets, high removable sides. At will, they make a roof and a retractable platform.

Assembly process

To obtain a platform, standard beekeeping car trailers are reworked:

- First of all, the frame is extended by at least 1 m by welding additional blanks from the profile and pipe.

- The bridge and springs are used from a UAZ car.

- The frame is visually divided into sections across. Usually there are 3 of them, 60 cm wide. A retractable frame for hives is welded from a square pipe. They put her on a sled.

- Under the hives, frames are welded from the corner, attached to the platform. The bottom is welded with sheet metal.

- The wheel of the sliding mechanism of the common frame for the hives is made of bearings. They are distributed evenly throughout the structure.

- The floor of the platform is laid out from the board. Along the side walls, loops are welded to tighten the hives with ribbons.

- The racks of the sides are welded at the corners of the frame and the center where the sled is located. The drawbar of the platform is reinforced with a pipe with a cross section of 40 mm.

- The roof frame is welded from the corner. Be sure to withstand the slope so that rainwater flows.

The final work is the laying of roofing material. Usually used tin, galvanized, corrugated board.

Models of trailers for transporting bee hives

Among amateur beekeepers, factory-made light trailers are popular for transporting bees. If it is not possible to make a platform on wheels yourself, you can always buy it, but it will cost the beekeeper a little more.

The video tells about trailers for transporting bees brand “MZSA”:

Beekeeper

The specialized trailer “Beekeeper” from the manufacturer “Progress” is equipped with a reinforced spring suspension that can withstand heavy loads while driving loaded on uneven dirt roads. The design is equipped with boards 15 cm high. The bottom is made of moisture-resistant plywood. The maximum permissible load capacity is 1 t.

Tandem

The manufacturer “Kurgan trailers” presented a two-axle model “Tandem” with a rolling wheel. The height from the ground to the bottom is 130 cm. The transportation of bees is carried out with hives installed in 1 row. During the parking of the apiary, the houses can be set up in 4 tiers.

Saddle apiary-24

From the manufacturer “Os” the saddle apiary trailer 24 is equipped with a retractable frame-stand for 8 beehives. The total capacity is 24 houses. The hitch is equipped with overrun brakes.

Model 817730.001

The compact towing device from the manufacturer “MZSA” is completely made of galvanized steel. Sheathing is made of moisture resistant plywood. For convenient loading of hives with bees, there is a folding board. Load capacity – 950 kg.

Rules for transporting beehives

Transportation of bees is done at night. The place is chosen at least 2 km away from the neighboring apiary. It is optimal to start transporting bees in the spring, and finish in the fall. Insects adapt better to a new place. During transportation, the frames are reinforced with pegs, provide good ventilation through the notch.

A place for an apiary is chosen closed by trees from the wind. A source of water is desirable. In the heat, the brought beehives are set to the north with tapholes. If the weather is cold, turn south. Letka open after calming the bees, after about 20 minutes.

Conclusion

The bee trailer helps the beekeeper bring the hives closer to the honey base. The presence of the platform additionally eliminates unnecessary loading and unloading operations. Which model to choose is up to the beekeeper.