Contents

If you intend to transport goods with a walk-behind tractor, then you can’t do without a trailer. Manufacturers offer a huge selection of bodies from simple models to dump trucks. However, their cost is quite high. With the ability to perform welding work, a do-it-yourself trailer for a walk-behind tractor can be done at minimal cost.

Varieties of trailers

The walk-behind tractor is a technique with limited traction power. You can’t thoughtlessly attach any trailer to it and load it as much as the height of the sides of the body allows. First of all, the choice of a trailer for a walk-behind tractor is carried out according to the size and carrying capacity:

- Light motoblocks are equipped with a motor with a power of up to 5 liters. With. For such units, the optimal dimensions of the trailer are: width – 1 m, length – 1,15 m. Maximum load capacity – up to 300 kg. The price of such factory-made trailers ranges from 200 USD. e.

- The middle class of walk-behind tractors is most in demand by private traders. Such equipment is already powered by a motor with a capacity of more than 5 liters. With. Trailers with a width of 1 m and a length of up to 1,5 m are suitable here. In the store, their cost ranges from 250 USD. e.

- Heavy-duty professional walk-behind tractors are equipped with motors with a capacity of 8 horsepower or more. The equipment is able to overpower a trailer with a width of 1,2 m, and a length of 2 to 3 m. For such dimensions, a strong support is required, which is explained by the presence of two axles. The price of factory-made trailers starts from 500 USD. e. During the transportation of goods, it is impossible to “squeeze out” everything that it can from the walk-behind tractor. From a strong overload, the engine overheats, accompanied by rapid wear of working parts.

The choice of trailers according to the type of design has a greater effect on the comfort of use:

- The cheapest to buy and easiest to manufacture are models with a one-piece body. The sides are permanently fixed to the bottom and cannot be opened during unloading.

- The best option in terms of price / ease of manufacture is a trailer with folding sides. Moreover, on the body it can open only one rear or together with the side ones. Such models are very convenient when transporting bulky goods, the main thing is that their weight does not exceed the permissible norm.

- Dump trucks are more expensive and more difficult to manufacture, but they are convenient for unloading bulk cargo.

Knowing what trailers are, you can think about a more suitable option for yourself.

Before buying a trailer, you need to consider that it is attached to the walk-behind tractor with a drawbar using a special towing device. There is a hitch mechanism on factory-made units. On a homemade trailer to the walk-behind tractor, you will have to make it yourself.

Even when choosing a model, you need to take into account the design features associated with the load capacity:

- Dump trucks designed for large payloads are always produced with two axles, plus they are equipped with hydraulics.

- Single-axle dump trucks, designed for light payloads, have a manual tipping body. To do this, it is placed on a frame with a shift in the center of gravity.

- Any type of trailer designed for a load capacity of more than 350 kg is equipped with a mechanical type brake. While driving with a large load, it will not be possible to stop the walk-behind tractor only with its native brake.

After familiarizing yourself with all the nuances of the device, you can go to the store or start making your own trailer.

Independent production of a trailer for a walk-behind tractor

For craftsmen and lovers of technology, we suggest that you familiarize yourself with the manual on how to make a trailer for a walk-behind tractor from the materials available on the farm. Let’s take a uniaxial model as an example.

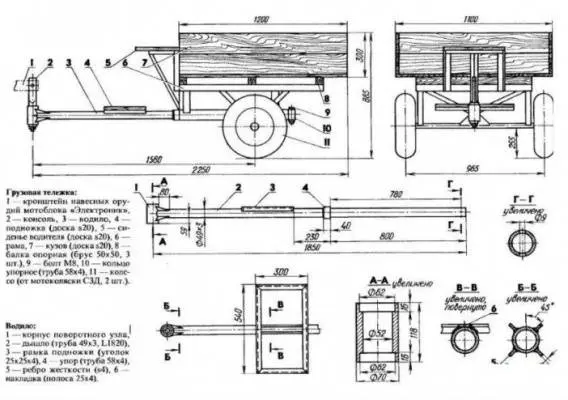

Drawing development

During the manufacture of a trailer for a walk-behind tractor, drawings will be required. They can be found ready-made. The photo shows a diagram with the dimensions of a single-axle trailer. You can take it as a standard or search the Internet for other drawings, and then modify them.

The scheme should display all the nodes of the structure, as well as the methods of fastening the elements. It’s good when you know how to draw drawings yourself. Then it will turn out to make just such a trailer with which it will be comfortable to work.

Frame and body manufacturing

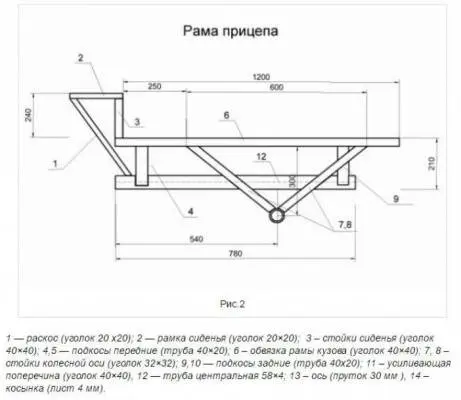

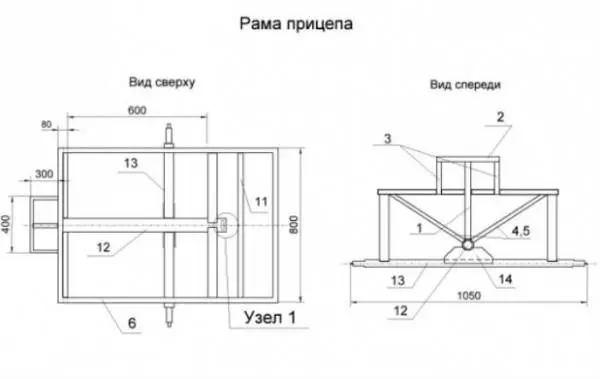

The frame is the basis of trailers for walk-behind tractors. A wheel pair and the body itself are attached to it. For its manufacture, only metal is taken. The frame is assembled in the following order:

- The frame lattice itself is welded from a profile pipe with a section of 60×30 mm. To give it rigidity, at least five crossbars are welded.

- At the corners of a rectangular lattice, racks are welded from pieces of pipe. Boards will be attached to them.

- From below, under the grate, two racks for the wheel axle and a drawbar are welded.

- The frames of the sides are welded from a corner with a section of 25×25 mm. Their further fastening to the racks on the grille depends on the chosen body type. The frames of the opening sides are hinged, and the stationary ones are simply welded to the racks and lattice elements.

As a result, you should get a frame, as shown in the presented drawing.

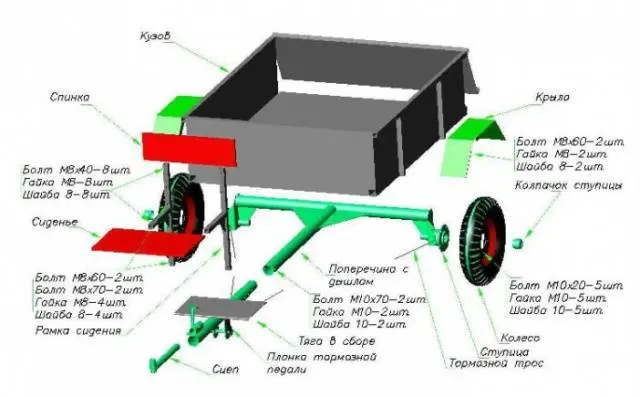

Wheel set installation

From the bottom of the frame, two racks for the wheelset were welded. Now they need to fix the axis to them. It can be removed ready-made from a passenger car or made independently. In the second option, hubs, bearings, wheels with disks will be required. The axis itself is best made from a steel bar with a diameter of at least 30 mm. The principle of assembling the wheelset can be seen in the photo.

Body trim

When the skeleton of the trailer is already on wheels, you can begin to sheathe the body. The choice of material for these works is small. Only two options are suitable: boards or sheet metal. As for wood, such a body will not be durable. Boards can be protected from moisture by impregnation and painting, but during loading and unloading operations, the possibility of damage cannot be ruled out.

The best option is sheet steel. For the manufacture of the bottom of the body, metal with a thickness of at least 3 mm is required. The sides can be sheathed with iron with a thickness of 1 mm. Some craftsmen have adapted corrugated board for these purposes.

A good combo body. Sheet steel is still taken for the bottom, and the sides are sheathed with a board 15 mm thick. There is even an option for making removable patches. With four shields from boards, you can quickly build up the sides when you need to transport light, but overall cargo in a trailer.

The video shows an example of making a dump truck trailer for a walk-behind tractor:

Trailer manufacturing

So, in our design, only the drawbar remained unfinished. It is necessary to organize a unit that will couple the walk-behind tractor with a trailer. Each factory-made unit has a special unit for installing a plow and other attachments. A trailer is connected here. There is no such node on homemade products, so you will have to do the manufacture of a tow hitch for a walk-behind tractor yourself.

The photo shows an example of hitching a trailer drawbar with a standard hitch made in the form of a shackle. The two elements are fixed with a steel pin. A similar bracket can be put on a homemade walk-behind tractor. Then it will be possible to install a plow, harrow and other factory-made equipment.

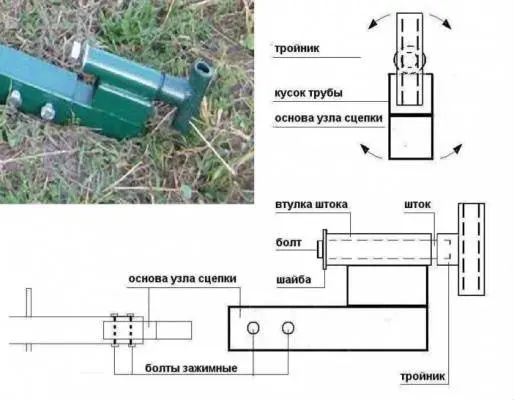

The next coupling option is represented by a movable connection. The tee of the trailing mechanism is fixed at one end inside the bushing on bearings. The design is welded to the drawbar, and connected to the walk-behind tractor with the same steel pin.

Such a rotating hitch for a plow and most other attachments will not work, but the trailer will vary perfectly on rough roads. The drawbar will rotate due to the bearings, which will save the hitch from deformation.

The video shows a coupling option for the MTZ walk-behind tractor:

Conclusion

On this, almost all the work on assembling the trailer is over. It remains only to equip the driver’s seat. It is attached to the drawbar or placed in the body. It all depends on the length of the towing device, because it is necessary that the operator of the walk-behind tractor has easy access to the control knobs.