Contents

The purpose of this article is to briefly introduce beginner moonshiners to the main processes that take place in sugar mash. Discuss the influence of various factors on the final result. We hope that after reading the material, when compiling your sugar mash recipe, you will act consciously, and not by touch.

Entry

Why do some people produce alcohol at a level of barely 500 ml/kg, while others easily reach 650 ml/kg for no apparent reason? Why does it happen that the mash is ready in 3-4 days, and sometimes it wanders for weeks?

To begin with, it is worth saying that sugar mash for vat distillation and for a continuous mash column are two big differences. If the goal of vat distillation is to obtain the maximum strength of mash, then for NBK the goal is to maximize the yield of alcohol per kilogram of sugar with a minimum fermentation time. For vat distillation, these factors are also important, but they fade into the background when we start counting losses.

Step-by-step technology for preparing sugar moonshine from laying the ingredients to distillation is at the link.

Loss of alcohol during vat distillation

Let me explain with an example: vat distillation – pour 10 liters of 12% mash into a cube and distill it as it should be into raw alcohol without selecting “heads” and “tails”.

Usually everyone is driven to 98-99 degrees in the cube, the rest goes to the sewer. The residual alcohol content of stillage is from 1 to 2,2%, let’s take the average – 1,6%. Q: How much alcohol will go down the drain?

With an average shoulder strength of 50%, we have a system of two equations with two unknowns:

X + Y = 1,2;

H / 0,5 + Y / 0,016 = 10, where:

- 1,2 – the volume of alcohol in 10 liters of mash;

- X is the amount of alcohol in the selection;

- Y – the amount of alcohol in the stillage.

We solve the system, we get that X = 1,07, and Y = 0,13.

Conclusion: with a mash strength of 12%, we send about 11% alcohol to the sewer. If the strength of the mash is 10%, then the losses will be 14%, but with a strength of 8%, a fifth will disappear.

Hence the desire for the maximum strength of the mash during vat distillation. We need to find the hydromodulus at which the sugar is completely fermented and the required maximum strength is reached.

Hydromodule – This is the ratio of the volume of water in mash to the amount of sugar in kilograms.

Rational hydromodule for vat distillation of mash

As you know, the theoretical yield of alcohol from 1 kg of sugar is 681 ml (this issue was discussed in detail in the article on the amount of alcohol from sugar), but in practice this figure is unattainable.

The main biochemical process of fermentation is the conversion of fermentable sugars into ethyl alcohol and carbon dioxide, described by the Gay-Lussac equation:

C6H1206 u2d 2C5H2OH + 02CO234,5 + XNUMX kJ / mmol.

From 180,1 g of glucose, 92,1 g of ethyl alcohol and 88 g of carbon dioxide can be obtained. But along with these primary products, part of the sugars is spent on the formation of by-products, resulting in not 92,1 g, but approximately 87 g of ethyl alcohol.

Thus, the practical yield of alcohol from 1 kg of sugar is not 184/342 = 0,538 kg/kg, but approximately 174/342 = 0,509 kg/kg or 0,645 ml/kg.

However, there are also production losses, for example, from 0,5 to 1,2% of alcohol can be lost along with fermentation gases at a temperature of 30 ℃ and depending on the strength of the mash.

The amount of water that needs to be added per 1 kg of sugar to achieve a given strength of the finished mash, we calculate by the formula:

V u53d 645 + 100 * (1 / Kb – XNUMX) – D, where:

- V is the required volume of water (ml);

- D – the amount of water in the yeast (for pressed 0,75 by weight, for dry it is 0, if the water for fermentation is taken from the fermentation tank, if not, then in fact);

- Kb – the strength of the mash (% vol.);

- 53 is the amount of water required for the sucrose cleavage reaction (ml/kg);

- 645 is the maximum practical yield of alcohol per kg of sugar (ml/kg).

For baker’s yeast, the strength of the finished mash is 12%:

V u53d 645 + 100 * (12 / 1 – 0) – 4783 u4,8d XNUMX ml, hydromodule XNUMX.

For spirits with resistance up to 14%:

V u53d 645 + 100 * (14 / 1 – 0) – 4015 u4d XNUMX ml, hydromodule XNUMX.

The obtained values of hydromodules can be considered only as the maximum for achieving a given strength.

Life makes its own adjustments. It is quite possible that dry yeast will withstand not 12%, but 12,5-13% of the strength of the mash, pressed sometimes present surprises, working up to almost 14%. That is, we cannot be sure about these figures, so determining the optimal hydromodule is beyond simple arithmetic.

If the sugar runs out and the yeast remains active, it will begin to ferment its energy reserve – glycogen, then the amino acids and proteins of their less powerful or dead counterparts. As a result, we get an excess of isoamyl alcohol, nitrogen and sulfur compounds with an indescribable “aroma”.

But even if there is no excess amount of water in relation to the capabilities of the yeast, and they fall asleep at the calculated strength of the mash, the process of producing impurities will continue. There are enough enzymes in the mash and in the cell fluid of the yeast, and they do not sleep. Therefore, you should not overexpose the mash on clarification.

Well, if fermentation is also carried out without a water seal, then oxygen and various microorganisms enter the container. Braga becomes infected with acetic acid bacteria and the processing of alcohol into vinegar begins. And the worst thing is that this process occurs with the release of gas. Braga gurgles, giving the impression that the sugar has not yet fermented.

It is considered correct to count the bookmark so that the yeast is guaranteed to fall asleep, leaving a small amount of unprocessed sugars.

Therefore, in the case of vat distillation for baker’s yeast, based on the criterion of the maximum mash strength of 12%, a hydromodulus of 4,5 is recommended, and for alcohol (14%) – 3,9.

Hydromodule of sugar mash for processing at NSC

If we are preparing sugar mash for processing at the NSC, then a fairly wide range of changes in the hydromodulus is possible here. Since alcohol is extracted from the mash by 100% regardless of its strength, the criterion of the strength of the mash fades into the background, and the influence of the hydromodule on the quality of the mash, fermentation speed and other parameters is evaluated.

To illustrate, we present the results of a well-known experiment. Under the same conditions, two containers with mash were delivered. The same amount of sugar from one bag is poured into both containers, dry baker’s yeast is added at the rate of 20 grams per 1 kg of sugar and water: 5 liters per 1 kg of sugar in the first container, 10 in the second.

Fermentation in the first container ended on the 5th day, in the second – 2 times faster.

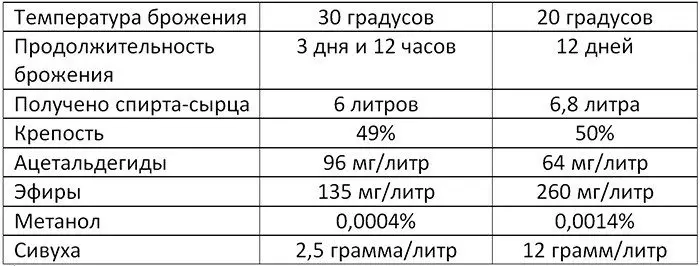

Dry distillation immediately after the end of fermentation showed the same amount of alcohol in both cases, but the composition of the raw alcohol was very different.

The amount of impurities in terms of absolute alcohol (mg / l)

| Hydromodule | 5:1 | 10:1 |

| Aldehydes | 100 | 143 |

| Ethers | 170 | 220 |

| Fusel oil | 7500 | 5200 |

| including: | ||

| propanol | 440 | 1100 |

| isobutanol | 1300 | 1000 |

| isoamylol | 5900 | 3040 |

Conclusion: a 2-fold increase in the hydromodulus led to a 1,5-fold decrease in the amount of fusel oil, but increased the amount of head impurities by the same one and a half times. The total amount of impurities is not more than 8000 mg/liter or less than 1%.

To assess the influence of the hydromodulus on the rate of fermentation, experiments were repeatedly carried out. For mash intended for distillation at the NSC, the optimal hydromodule is 5,8-6.

In the absence of any additives, acidification, fertilizing and the introduction of yeast in an amount equal to 10% of the weight of sugar at a laying temperature of about 30-32 degrees, already on the third day we get mash ready for distillation. With a decrease in the hydromodulus to 4,4, the fermentation time increases by a day.

Braga fermentation temperature

This is of particular importance for vat distillation. With the same bookmark, fermentation can stretch from two days to 5 or even more, depending on the ambient temperature and the volume of the fermentation tank.

Fermentation at a temperature of about 30 degrees is optimal for most dry baker’s yeast; after self-heating, the temperature can reach 34-36 degrees. There is nothing to be afraid of, this is normal. But at a temperature of about 25-27 degrees, fermentation can last even 5 days, and at 20-23 degrees, you can be surprised to find that fermentation has not ended even after a week.

In addition, it should be borne in mind that self-heating begins to manifest itself only in containers from 60 liters, in small 10-20 liter containers its influence is negligible, so they need to be more carefully insulated.

For large containers with a capacity of about 200 liters, in the summer, the self-heating process is so large that it requires constant monitoring and regulation of the temperature, since for most dry baker’s yeast, the temperature of mash at 38-40 ℃ is critical. You need to lower the temperature gradually, since temperature shock can lead to death of the yeast. It is best to provide in advance a small coil in the tank with the possibility of supplying cooling water.

When using alcohol or wine yeast, you should carefully read the instructions. Some races are not friendly with elevated temperatures and die already at 30-32 ℃. But alcohol and wine yeast for sugar mash is a clear overkill.

Yeast

The amount of yeast has a very serious effect on the speed and completeness of fermentation. At a sugar concentration above 10%, the yeast loses the ability to multiply. The concentration of sugar in the bookmark, even with a hydromodule of 4,5, is under 20%. Therefore, yeast has to contend with sucrose in its starting composition and special attention must be paid to its initial conditions. The main criterion should be the freshness of the yeast, and the brand on the pack is of secondary importance.

It is generally accepted to add yeast at the rate of 20 grams of dry or 100 grams of pressed per 1 kg of sugar. The ratio between dry and pressed is explained simply: in the pressed, about 75% of water and 25% of the yeast itself. This also explains the feeling that pressed ones seem to work better in these proportions. There are just more of them!

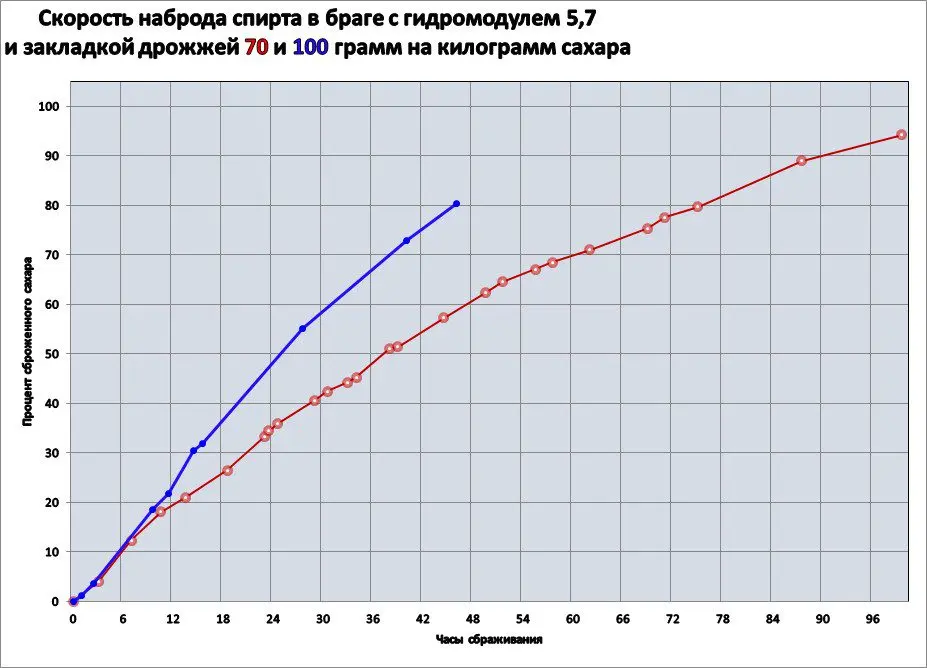

Adding less yeast leads to a significant increase in fermentation time. For example, if you put in 70 grams of pressed yeast instead of 100, then you need to be prepared for doubling the fermentation time. It is very important to use yeast close to the recommended one, this will not only reduce the fermentation time, but also the amount of unnecessary impurities.

You also need to pay attention to the materials used in the fermentation tanks. Copper is a poison for yeast, so no contact with copper pipes, utensils, etc. until the end of fermentation.

Sugar

The technology for obtaining sugar, even at the same plant, can be different. During refining, its solution is carbonized. For this, both charcoal and bone charcoal are used, and the second is more effective for clarification, discoloration of sugar.

Therefore, when choosing refined sugar, you need to focus not so much on the manufacturer, but on the smell and color. The use of bone charcoal gives the sugar a slight smell of casein.

The yellowish color of granulated sugar indicates its less purification and a possible alkaline reaction in solution (weak pink coloration of phenolphthalein). Our colleagues have come across this quite often in recent years.

Yeast needs an acidic environment, so it makes sense to adjust the acidity by adding one to two grams of citric or phosphoric acid per 1 kg of sugar. If you are too lazy, then fermentation can be delayed. However, you need to know the measure – an excessive increase in the acidity of the mash leads to a significant increase in the total number of metabolites and a decrease in the alcohol content in mature mash.

The optimum pH for alcoholic fermentation is about 4-4,5.

Lightening

If the proportions in the batch are chosen correctly, then the yeast falls into suspended animation, having processed all the sugar or leaving it to a minimum in the mash. In this case, there is a rapid clarification of the mash within literally 10-12 hours.

If there is not enough sugar for the yeast to develop the concentration of alcohol required to stop the activity in the mash, then you should not wait for clarification. You need to immediately distill the mash. Otherwise, the accumulated enzymes, in the absence of an alternative, begin the process of autolysis – yeast self-fermentation.

If there is no way out and timely distillation is impossible, then you need to add “tails” from the previous distillation to the mash. Raising the strength of the mash by 3-4%, we will not only begin the process of rapid clarification, but also preserve it.

Interestingly, if the sugar in the solution is more than 20%, then the yeast is initially under the influence of high osmotic pressure. Some of them die immediately, and autolysis begins. Fermentation is delayed, impurities are accumulated to the maximum.

Both insufficient and excessively large amounts of sugar lead to smelly moonshine. It is clear that the same can be said about the hydraulic module – these are interconnected things.

The clarification process adds 1-2 percent to the strength of the mash, but during this time up to 30% of all impurities are produced. And first of all, esters – as a result of the reaction of acids with alcohols. To reduce the production of impurities during clarification, it is necessary to carry out the entire process at low temperatures, for example, in a cellar.

If the mash is further sent for rectification, then it is better not to clarify it. The accumulated esters are a very difficult to remove impurity. If moonshine is the final stop, then the formed esters will soften its taste, and the non-condensable gaseous compounds of nitrogen and sulfur that have escaped during clarification reduce the unpleasant smell of the distillate.

Lightening makes sense for fruit and berry brews. Here, on the contrary, it is necessary to keep the wine on yeast for as long as possible to produce enanthic esters. It is on their basis that the aroma of the future drink will be formed.

Bentonite for forced clarification

Clarification with bentonite came to us from winemaking. There, settled and decanted wine is clarified from the dry residue. Despite this, sediment is allowed in the best wines even after many years of aging.

For the production of raw alcohol, the use of bentonite to clarify the mash is an absolutely useless, and in certain cases, harmful technological method. Bentonite does not improve the quality of raw alcohol.

The only visible benefit from lightening the mash, including with the use of bentonite, is some of its degassing. This allows you to reduce the foam in the cube and increase the bulk from 2/3 of the cube to 80-90%.

The real need for this may arise only when processing large volumes of mash in relation to the capabilities of the equipment. On the other hand, if, when heating the mash in a cube, upon reaching a temperature of 70-75 degrees, pause, stopping the heating for 20-30 minutes, then the degassing of the mash will be much more complete.

It is especially worth warning against the use of bentonite by moonshiners who use NBR or even just copper rings for the first distillation.

The reasons are clear and akin to those due to which it is strictly forbidden to drain the bentonite sediment obtained after clarification into the sewer:

- getting even a small amount of bentonite suspension into the nozzle entails its persistent contamination, which is almost impossible to wash out.

- the slightest traces of bentonite in the wash dramatically change the surface properties of the nozzle;

- when the mash runs out, the pump will start pumping the sediment. In the presence of bentonite, this will clog both the hoses with the pump and the nozzle, pushing the horizons for a labor feat every minute.

In general, it is better to leave bentonite to cats, and save yourself time and money.

Invert

Among our colleagues who prepare sugar moonshine in small quantities for consumption, and not as a raw material for further rectification, the preparation of mash on inverted sugar is common.

When sugar is dissolved in water, its crystals break down into sucrose molecules, which are glucose and fructose molecules joined together. Only a small part of the sucrose will break down into its constituents.

If you add citric acid to the solution and boil for 2 hours, then 70-80 percent of sucrose will fall apart into components. Moreover, up to 85% of fructose will not be in an expanded form, which is processed by yeast, but in an annular form. This solution is called invert.

Difference in fermentation process

If yeast is added to an ordinary sugar solution, they, processing a few glucose, immediately begin to produce the enzyme invertase (sucrose). This enzyme acts as a catalyst for the breakdown of sucrose into components and converts fructose into the desired form. Enzymes work autonomously and accumulate in solution. The higher their concentration, the faster sucrose is converted into fermentable forms. With an increase in the concentration of alcohol, the production of enzymes decreases, but their concentration by this time is already excessive.

First of all, the yeast processes glucose, and only when it runs out they move on to fructose already converted into fermentable forms. Yeast, although reducing its activity with an increase in the alcohol content of the mash, finishes its work as quickly as possible.

With preliminary inversion from the very beginning, there is a lot of glucose and unfermentable fructose in the solution, and a certain amount of undecayed sucrose. As long as glucose is above 0,4%, yeast does not produce enzymes that break down sucrose and convert fructose into a fermentable form.

After a couple of days, having rapidly fermented almost half of the alcohol, the yeast is faced with the need to change the diet. But during this time no one tried to isolate enzymes and there are simply no fermentable forms of fructose. Yeast activity has already faltered under the load of fermented alcohol. But there is nowhere to go, and the production of fermentase begins. Two days of glucose bacchanalia were not in vain, and now they need to be made up. Therefore, the second stage of fructose fermentation is delayed, and fermentation is less intense. So much slower that many moonshiners, without waiting for complete fermentation, stop the process, while noting that the yield of alcohol is 50-70 ml less per 1 kg of sugar.

In general, as experiments show, the time of complete fermentation of mash with inverted sugar is about a day longer than with regular sugar. The output of the finished product does not noticeably differ. There are fewer various impurities with an unpleasant odor and fuselage. Taste, if this concept can be applied to sugar moonshine, is higher.

If the goal is moonshine, it’s worth inverting. If raw alcohol is intended for further rectification, inverting sugar is an unnecessary waste of time and money.

The author of the article is IgorGor.