The thermometer in the cube should give the most reliable information for a correct assessment of the course of the distillation process. At the same time, the main question is not where to put the thermometer, but why put it at all? What do we want to see or calculate from his testimony? If you deal with these questions, the rest of the points will become obvious.

So let’s start with simple questions. The first of them: what is the bulk strength in a cube? To answer, it is enough to know the boiling point of the bulk at the current moment.

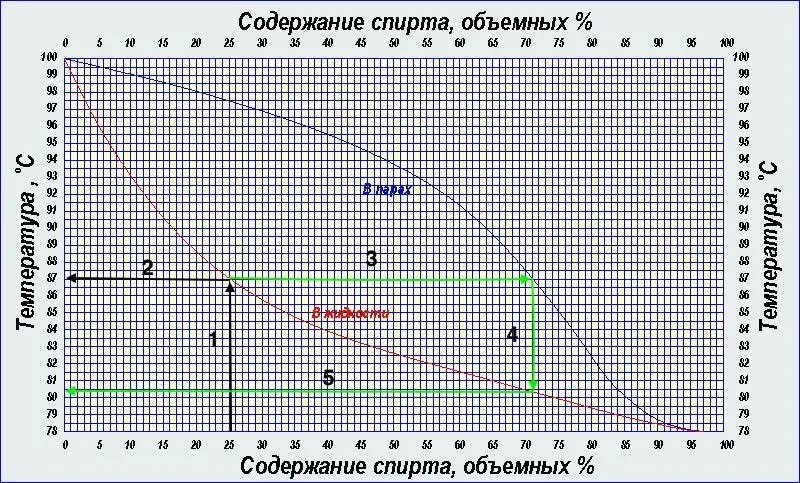

Legend:

- T1 – bottom bulk temperature;

- Т2 – steam temperature;

- T3 is the steam temperature at the column inlet.

Everyone is confused by the incorrect term – “cubic temperature”. It is possible to measure directly the temperature T1 in the liquid zone or the steam temperature T2. It seems that in both cases this is the “cubic temperature”, but this is not so. If we measure the temperature of the liquid T1, then we get it. But having learned the steam temperature T2, in the future we can only assume that it is equal to T1.

At the moment of steam separation from the boiling surface, indeed, T1 = T2. But every moment the steam loses its temperature. At the exit from the cube to the column, it is much colder than the boiling bulk.

The degree of cooling of the alcohol vapor depends on the heat loss through the side walls and the lid of the cube. The relatively cold phlegm pouring from the column also makes a significant contribution. How big is this error? The measured steam temperature can range from the vaporization temperature to the condensation temperature.

The width of this corridor can be clearly seen with the help of the well-known “fish”.

Suppose that a 25% alcohol solution is boiling in a cube. Climbing along arrow 1 until it intersects with the graph of the boiling point of the liquid (red curve), then we turn along arrow 2 and determine the boiling point (vaporization) – 87 degrees. Following the arrows along the route 1-3-4-5, we determine the condensation temperature of the resulting steam – 80,5 degrees. This means that a temperature probe sticking out somewhere in the steam zone will show a temperature of 80,5 to 87 degrees.

The longer and closer to the boiling surface the probe is, the less cooled steam it will meet, and the closer the thermometer readings will be to 87 degrees, and vice versa, the shorter and closer to the flowing phlegm, as well as the lid of the cube, the probe will be, the closer its readings close to 80,5 degrees. If the thermometer is also inserted into a thick sleeve welded to the lid, then the sleeve, like a large radiator, will remove heat, and the thermometer readings will become even more unpredictable.

The measurement error will become negligible if you boil in a cube a liquid close in composition to pure alcohol or water. In this case, the difference between the condensation temperature and the vaporization temperature will tend to zero, along with a possible measurement error. But here’s the problem – this range is not interesting for distillers.

The maximum difference and possible error falls on the distillation range – 93-98 degrees, and the error can be up to 12 degrees.

This is the corridor in which, depending on the heat loss, the steam temperature will be, that is, the maximum error value. In fact, this does not happen. The better the cube and its lid are insulated, the less heat loss, and the value of T2 is closer to T1.

But there is a price of error… Suppose the thermometer in the steam zone showed 98 degrees, we stopped the selection, thinking that only 2% alcohol was left in the cube. In fact, the temperature of the bulk was 97 degrees and the alcohol content was about 1,3% higher. With a cubic pile of 30 liters, this is 400 grams of lost 96% alcohol or 2 bottles of vodka. The premature transition to “tails” wrote off about the same amount for re-rectification. This is because the tip of the thermometer was not in the liquid zone and with an error of only 1 degree. If the cube is poorly insulated, the sting is far from the bulk surface and the error is much larger?

Determining the bulk temperature from the steam temperature has an error of an indeterminate value, the maximum error value is unacceptable, since the loss of alcohol will be very large.

Knowing the exact value of the temperature of the bulk, it is possible to determine its current strength and the alcohol content in vapors at the column inlet. Having the strength of the product at the outlet, it is realistic to estimate how many separation stages (theoretical plates) the column is currently working with.

This is a very important and necessary temperature, the only one of all, the absolute value of which must be determined with maximum accuracy.

The bottom temperature is the temperature of the bulk (liquid), it must be measured directly without the mediation of steam, by lowering the thermometer into the liquid zone.

Indeed, what benefit can be expected from an intermediary, except for corrupted information?

How to choose an alembic thermometer

Any thermometer has an accuracy class. This is an important parameter to pay attention to. Often unscrupulous manufacturers complete the sold cubes with bimetallic thermometers with an accuracy class of 2,5. This means that when measuring temperature, the maximum error will be 2,5% of the maximum value on the thermometer scale.

If the value is 120 degrees, then the error can be up to 3 degrees. For example, if we are going to cut off the “tails” at a temperature of 94 degrees, and finally see this temperature on a thermometer, then in fact the real temperature can be from 91 to 97 degrees. And this is in addition to the influence of other factors discussed above.

With an accuracy class of 1,5, the maximum error would be 1.8 degrees. With the same accuracy class, a thermometer with a lower maximum value of the measured temperature will be more accurate.

As a rule, electronic thermometers give a higher accuracy class. Even a household kitchen thermometer has an accuracy of plus or minus 1 degree with a division price of 0,1 degrees, but not everything is so simple. Absolute temperature measurement accuracy and resolution are two different things. Such thermometers are justifiably used in columns where it is not the temperature itself that is important, but its change. This is where 0,1 degrees comes into play. When measuring the bottom temperature, it will certainly give a more accurate temperature than a bimetal thermometer, but you should not expect miracles.

For a more accurate measurement of the temperature of the cubic pile, electronic thermometers of the T-0,36-DS-A type with an external temperature sensor are used, in which the resolution and measurement accuracy are 0,1 degrees. True, the measurement range is more modest: from -55 to 125 degrees, but for the purposes of distillation – just right. There is also a drawback – the DS18B20 temperature sensor requires a sleeve to be placed in a cube.

The simplest and most affordable option for placing a temperature sensor is in the heating element sleeve. When installing, it is enough to bend it a couple of centimeters to the side and up from the heating elements.

If a decision is made to install a sleeve, simple requirements must be observed: the temperature sensor tip must be at some distance from the heating element, the bottom and walls of the pan. At least a couple of centimeters. But you don’t need to get carried away either, the sleeve should not interfere with the installation of additional equipment, such as a false bottom. Also, the sleeve should not be massive, as this does not contribute to the accuracy of measurements. Well, if the inner diameter of the sleeve approaches the diameter of the thermal sensor, the use of thermal paste is welcome.

conclusions

- The bottom temperature thermometer should only be placed in the liquid zone.

- When choosing a thermometer, you need to pay attention to the accuracy class, measurement range and resolution.

The author of the article is IgorGor.