Contents

Ceramic brick is one of the oldest materials for building houses. Over time, the technology has not changed much. To improve the thermal performance, they came up with the idea of making voids. To reduce the time for construction, they began to produce products of large sizes. The assortment has increased. One size of ceramic brick is clearly not enough for modern construction. But the essence of production and the materials used remained the same. As are the problems.

Pros and cons of ceramic bricks

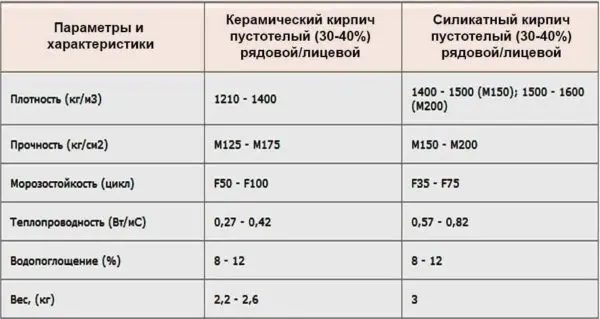

The advantages of ceramics include naturalness, harmlessness. If we compare ceramics and silicate, then clay products win a little in terms of thermal conductivity. If you look at the figures, the difference is quite small. But a ceramic house is much warmer than a silicate house. It’s more about heat capacity. Clay can store more heat and therefore houses from it are warmer.

Ceramics loses to silicate in terms of soundproofing properties, as well as in terms of geometry and stability of characteristics. This is its main shortcomings. Moreover, at a high price, often occurring efflorescence, which is very, very difficult to deal with. Another disadvantage is that even the front surface is rarely even.

All these shortcomings are understandable. Ceramic bricks are obtained by firing preformed parallelepipeds from clay mortar. Clay is a natural material that has various properties. The different properties of different types of clay is the main reason that the size of ceramic bricks does not differ in stability. Moreover, a significant variation can be within the same batch. And from party to party, in general, there can be significant differences. The different characteristics of the feedstock also cause a wide variation in the characteristics of the finished product. such as strength and density.

Service life – reality does not please

According to many characteristics, ceramics should be better than the same silicate, but the reality turns out to be different. Recently, red ceramic brick crumbling, dilapidated after several years of operation under normal conditions is too common. The reasons are the complexity of the technology. For a good result, careful processing and preparation of clay is necessary in order to exclude lime inclusions, which are the causes of “shootings”. And this is additional time in an already not short production cycle. And extra energy. And expensive equipment that not everyone buys.

The second point: exposure of the firing temperature regime. Burnt ceramic brick in masonry behaves normally. It only looks worse, as it is darker than the “norm”. It’s not so scary. But the unburned is destroyed, crumbles. And that’s why he’s dangerous. Ceramics are fired in the kiln for a long time, and so it takes a little to shorten the time in order to increase productivity. Hence the malaise. Or from fuel economy, which is far from cheap. So compliance with the production technology of ceramic bricks is a high price of products. And expensive bricks are bought very reluctantly. So the destroyed red brick, most likely, had a low price. And everyone knows that cheap good is very rare. Nevertheless, the construction budget is usually not rubber and you have to save.

No matter how complex the production technology is, European deliveries have a geometry close to ideal, standard sizes, and stable quality. Their price is far from budget, but quality problems are a rarity. So if funds allow, they try to buy imported bricks. Domestic clay, even expensive, can not yet boast of stable quality. That is why, although in many respects ceramics should be better, more and more often the choice is made in favor of silicate. Because for quite sane money you can buy good quality building material. It is chosen even though it is much “colder”. Anyway, to achieve the required level of energy efficiency, ceramics also have to be insulated.

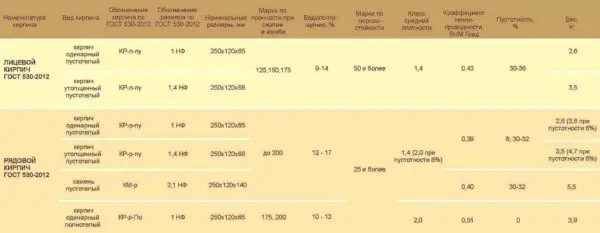

Types and size of ceramic bricks according to GOST 530-2012

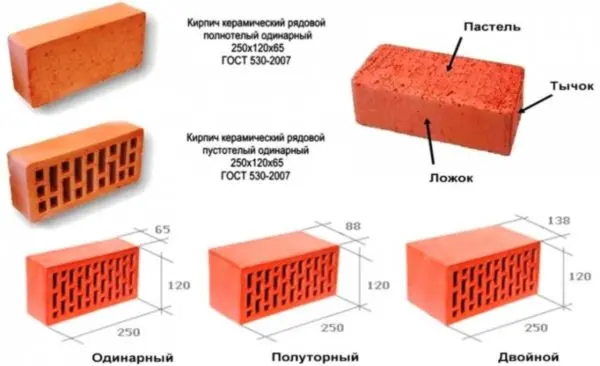

By size, ceramic products are divided into brick and stone. Ceramic building stone differs only in greater thickness – at least 140 mm. Clay bricks can be solid and hollow, ordinary (construction) or finishing (facial). Ceramic stone – only ordinary and only hollow. Voids in a clay stone or brick can be located either parallel to the bed (the work surface on which the mortar is placed) or perpendicular. In addition, the standard defines the following types of products:

- Shaped brick. A product that differs in shape from a parallelepiped.

- Complementary element. The shape is designed specifically to complete the masonry.

- With tongue-and-groove system. Ceramic stone, the vertical edges of which are specially shaped for joining without mortar. The dimensions of the protrusions are not standardized. There are two special sizes for this type of material:

- Working width of the stone. This is the size without tongue-and-groove protrusions. It forms the width of the masonry.

- Non-working length of the stone. The distance from one vertical surface to another, including protrusions.

Another stone and brick can be with a polished or unpolished bed (this is the part on which the mortar is placed). Some factories produce material with notches on the spoon. This type is convenient to use if the wall will be plastered. Notches are needed for better adhesion with plaster.

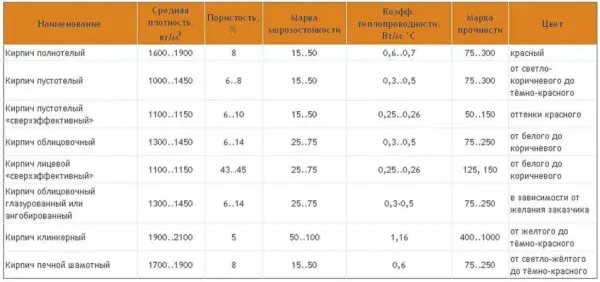

There is also clinker brick. It has a more complex manufacturing technology, which gives it special properties. It is stronger than conventional construction, has a lower water absorption. Its surface is perfectly even and smooth, which makes it possible to use it as a finishing material. But this is a separate group of products.

Standard dimensions and designation of ceramic building (ordinary) bricks

According to the GOST 530-2012 standard, there are the following sizes of ceramic bricks:

- Normal format or single. In the marking put NF. It has dimensions 250*120*65 mm. According to the previous standard (GOST 530-2007), this brick size was called single. If this is a material for masonry walls, put KR (ordinary). It can be full-bodied or with vertically arranged voids. According to the same standard, there are its subspecies:

- 0,5 NF – 250 * 60 * 65 mm.

- 0,7 NF – 250 * 85 * 65 mm.

- 0,8 NF – 250 * 120 * 55 mm.

- 1,3 NF – 288 * 138 * 65 mm. This is an enlarged size.

- 1,4 NF – 250 * 120 * 88 mm. This is the species that, according to the old standard, is called one and a half.

- 1,8 NF – 288 * 138 * 88 mm. This is what is called double.

The old standard described the dimensions of ceramic bricks differently.

- С horizontal voids – designation KRG. There are only two sizes:

- 1,4 NF – 250 * 120 * 88 mm.

- 1,8 NF – 288 * 138 * 88 mm.

These are the dimensions that are defined for ceramic bricks by the new standard. As for the coefficients, they are calculated as a fraction of the volume occupied by ceramic bricks of a standard size – 250 * 120 * 65 mm.

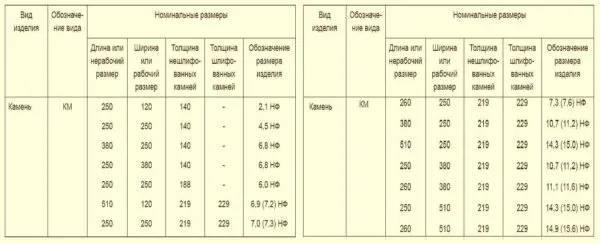

Types and sizes of ceramic stone

As you can see, there are two subspecies of ordinary ceramic (building) bricks, the width of which is 138 mm. At the same time, the standard says that all products with a width of 140 mm or more are called ceramic building stone. So the difference of two millimeters, in this case, is significant.

The size of the ceramic stone is given in the tables. In parentheses are the designations of dimensions for products with ground edges. In general, building walls from a large type is much faster, and a square meter of masonry is cheaper. Savings come from the solution. But you can’t work alone. One block, although they are all hollow, can weigh more than ten kilograms. You can install them only together, as well as adjust the position. By the way, the standard allows making voids in the side faces for grips (for more convenient transfer) with a total volume of no more than 13%. This really makes it easier to work with large format blocks.

Full and hollow

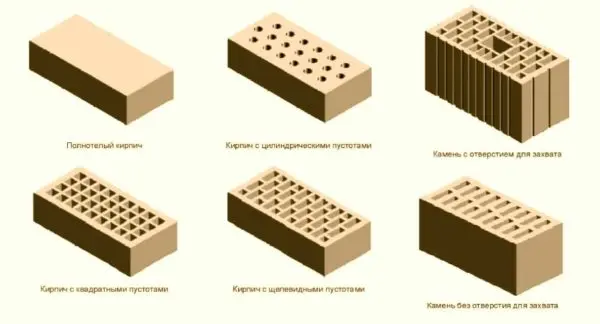

Solid and hollow ceramic bricks, although produced in the same way, have different purposes. Material without voids goes to load-bearing walls, with voids is taken for better thermal insulation performance. Since the presence of air cavities makes the material “warmer”. It conducts heat worse, which means it saves it better. In the marking, full-bodied is indicated by the letters “po”, with voids – by the letters “pu”. The number of voids and their volume is not indicated anywhere. They need to be looked at locally.

It is necessary to take into account such a feature of the introduced standard. Solid brick GOST 530-2012 is defined as a building material without voids or with voids less than 13%.

In general, solid bricks are used for walls that can bear a large load. If the bearing capacity of the masonry is important to you, it is necessary to specify not only the brand of products in terms of strength, but also the presence of voids. In a solid brick, their size and location are not standardized in any way (if they are less than 13%).

In hollow brick and stone, the diameter of vertical cylindrical voids cannot exceed 20 mm. If the void is square or rectangular, its side also cannot be more than 20 mm. The position and size of the horizontal voids are chosen arbitrarily, which is worth remembering. Only the minimum outer wall thickness has been determined. It should not be less than 12 mm for brick and 8 mm for stone.

TECH SPECS

The standard defines strength grades, frost resistance and density class. Strength grades represent the load that a material can bear. It is easy to decipher this value. The number that follows the letter “M” is the number of kilograms per square centimeter that the material can withstand without destruction. Example: M150 indicates that the ceramic brick of this batch will withstand a load of 150 kg / cm².

| Strength grades | Ceramic brick | M100, M125, M150, M175, M200, M250, M300 |

| ceramic stone | M300, M400, M500, M600, M800, M1000 | |

| clinker brick | M25, M35, M50, M75, M100, M125, M150, M175, M200, M250, M300; | |

| Brick and stone with horizontal voids | M25, M35, M50, M75, M100 | |

| Frost resistance | F25, F35, F50, F75, F100, F200, F300. | |

Strength and frost resistance grades for ceramic stone and brick are indicated

Frost resistance is indicated by the letter F and a number. The number represents the number of freeze/thaw cycles that do not cause any change in performance or appearance. For example, F50 – 50 freeze and defrost cycles. For internal partitions in heated buildings, frost resistance can be taken low – a positive temperature will still be maintained.

Thermal conductivity and thermal resistance coefficient

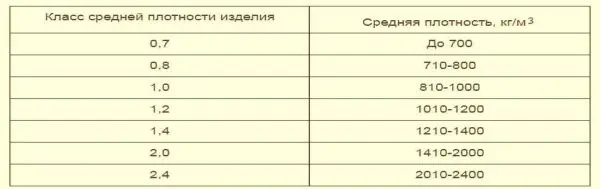

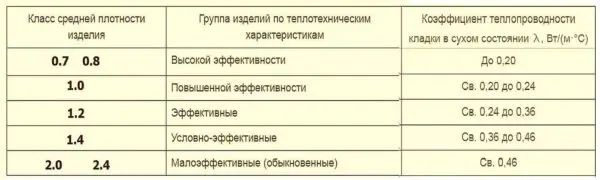

The density class corresponds to the average density of the material, but the energy efficiency of the material also depends on the density. The lower the density, the better the thermal insulation properties. But it will not work to significantly reduce the density for external walls. They must carry a certain level of load. Therefore, in recent years, a brick house has been made with insulation.

How to work with the last two tables? The marking indicates the density class. According to this characteristic, you can find out the mass of a cube of ceramic bricks. It is listed in the first table. The second table helps to compare the density of the material and the thermal conductivity of the masonry from it. For example, the density class of ceramic bricks is 1,0. This means that the cube should weigh 810-1000 kg, and the masonry on the minimum layer of glue after drying will have a thermal conductivity coefficient of 0,20-0,24 W / (m * ° C).

It is worth saying that according to modern standards, none of the types of bricks provides the necessary heat resistance. Unless the thickness of the wall will be more than a meter.

In this case, a hollow brick or building ceramic block wins, as they have better thermal conductivity characteristics. The wall will be a couple of tens of centimeters narrower – not 147 cm, for example, but only 105. So, in any case, it is worth considering additional insulation of the outer walls.

Weight of ceramic brick

The weight of ceramic bricks depends on the density and the presence/number of voids. The exact figure will be found out in the accompanying documents, and then, the spread within one batch is up to 10%.

If you use the old terminology, the approximate weight of a ceramic brick will be as follows:

- Single (type 1 NF, size 250*120*65 mm):

- full-bodied (ordinary, masonry, construction) 3,3-3,6 kg / pc;

- worker (ordinary, masonry) hollow – 2,3-2,5 kg / pc;

- facing (front, finishing) hollow – 1,32-1,6 kg / pc.

- One and a half has a mass (type 1,4 NF, dimensions 250 * 120 * 88 mm):

- full-bodied private – 4,0-4,3 kg / pc;

- hollow ordinary – 3,0-3,3 kg / pc;

- front hollow – 2,7-3,2 kg / pc.

- Double weighs (1,8nf 288*138*88mm.) :

- ordinary corpulent – 6,6-7,2 kg / pc;

- ordinary hollow – 4,6-5,0 kg / pc.

We give an approximate weight, since the density and number of voids for each plant can vary significantly. The number of voids is not regulated, so finishing materials can be light.

Ceramic brick marking

The marking of ceramic bricks indicates complete information about its type. The size of the brick is indicated in millimeters in the format: length * width * height. Be sure to indicate the main characteristics given above. To decipher the information, you need to remember the conventions for each type of material:

- K is a brick

- Kl – clinker.

- R – ordinary (construction).

- L – front (finishing, decorative).

- G – horizontal voids.

- Po is full-bodied.

- Pu – empty.

- Ш – polished.

- Pg – tongue-and-groove.

After specifying the dimensions, the strength class, medium density class and frost resistance are indicated through the oblique. Here are some examples of marking and its decoding:

- KR-r-by 250*120*65/1NF/200/2,0/50. You need to read it like this: ceramic brick (KR), ordinary (p), full-bodied (po). Size 250 * 120 * 65 mm, 1NF – format and dimensions. Next come: strength class M 200, medium density class 2,0, which corresponds to 1410-2000 kg / m³, frost resistance F50 (50 cycles).

- KRG-l 250*120*88/1,4NF/50/1,2/75. It sounds like this: ceramic brick (KR), with horizontal voids (G), front (l). The size of the ceramic brick is 250*120*88 mm, size 1,4 NF. Strength class M50, medium density class 1,2, which corresponds to a weight of 1010-1200 kg / m³. Frost resistance 75 cycles (F75).

- KM-pg 510/10,7NF/150/0,8/75. This designation is deciphered as follows: ceramic stone (KM) with tongue-and-groove connection (PG), working part size 510 mm, size 10,7 NF. Strength grade M150, density class 0,8 (energy efficient), frost resistance F 75.

The new labeling method is closer to EU standards. The standard does not prohibit plants from specifying additional characteristics in accompanying documents. It is also possible to put additional information on the packaging, which facilitates the identification of the manufacturer.