Without artificial or wild yeast, moonshine is impossible in principle. It is these microorganisms that convert glucose into alcohol. Alcohol is a waste product of their life. This article is devoted to determining the amount and nuances of activating yeast for sugar mash. All proportions are obtained experimentally and have been tested many times in practice.

When choosing yeast for moonshine, it is better to focus on alcohol types designed specifically for these purposes. Everything is simple here: in the instructions, manufacturers indicate how much sugar a pack is designed for. But while alcohol yeast is not sold in every store, it is still difficult to get it in small towns. Therefore, further we will consider mash recipes based on raw pressed and dry yeast used for baking. With the right approach, they also make good moonshine.

Braga with pressed yeast

For ten liters of forty-degree moonshine you will need:

- sugar – 8 kg;

- water – 32 liters;

- raw pressed yeast – 0,5 kg;

- raw potatoes – 2-3 pieces (optional).

On specialized forums on the Internet, they constantly argue about the correct proportions of ingredients for moonshine. Many recipes use more water than I suggest. But practice has shown that an increase in the volume of the mash does not lead to an increase in the yield or an improvement in the quality of the distillate. Raw potatoes speed up fermentation because they contain trace elements that yeast needs. First, the tubers are cleaned and passed through a meat grinder, then added along with yeast.

Braga recipe with dry yeast

It is believed that it is impossible to make good mash with dry yeast. In fact, you just need to know the proportions and some of the nuances of cooking. Any dry yeast will do, such as Saf-Levure, Saf-Moment, or Pakmaya. They are usually sold in bags of 100 grams. The optimal ratio between dry and raw yeast is 1:5 or 1:6. For 8 kg of sugar, add one and a half bags of dry yeast.

Before being added to the sugar solution, dry yeast is diluted, moonshiners call this “fermentation”. The powder is poured into 0,5 liters of warm water (not higher than 30 ° C), allowed to stand for 5 minutes, then slowly stirred until completely dissolved. The optimum temperature of the sugar solution before adding yeast is 20-24 degrees.

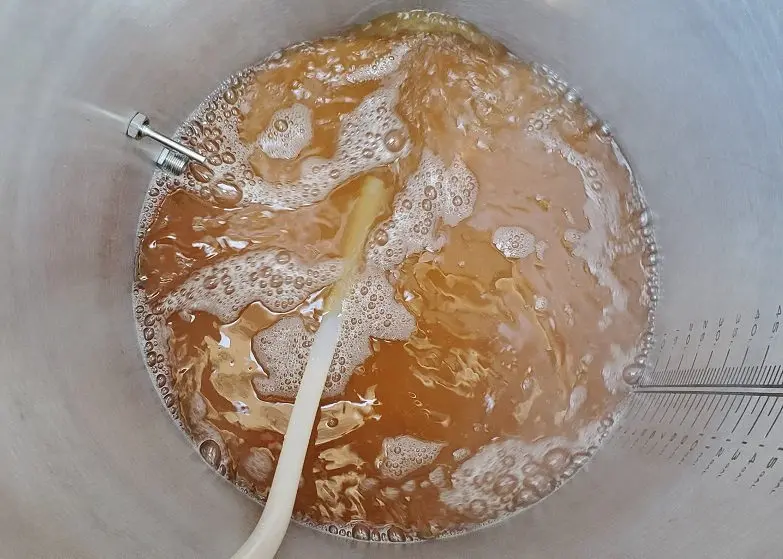

Sometimes the first few hours of mash on dry yeast behave unpredictably: either it does not ferment at all or abundant foaming begins. To extinguish the foam, add 50 grams of vegetable oil to the container. In some cases, the oil has to be topped up 2-3 times. If foam is abundant, do not cover the container with a lid, otherwise a small explosion may occur.

Regardless of the chosen yeast, the mash will be ready for distillation no sooner than in 4-7 days. The mash that has won back brightens and is a little bitter. If sweetness is felt in the taste, add 25% of water by volume, mix the contents of the container thoroughly and let stand for another couple of days.