Sooner or later, all owners of column-type apparatuses face the problem of choosing the optimal packing. Usually the decision is made based on the recommendations of the column manufacturer or advice on the forums. The problem is that often the information on popular Internet resources is not objective, since the manufacturers and sellers of nozzles explicitly and implicitly sponsor posts that praise their offspring. In this article, we will try, based on calculations, to objectively evaluate the properties of the most popular nozzles: spiral prismatic (SPN), regular wire (Panchenkov mesh, RPN) and household metal washcloths.

When choosing a packing, the main criteria are throughput and separating capacity. Important, of course, weight and price. Let’s link all these indicators to each other to understand what we get for our money.

Let us make a reservation right away that the separation and throughput of the column depend not only on the properties of the packing, but also on other factors: reflux ratio, heating power, vertical position of the column, quality of filling of the packing, heat loss, etc. Therefore, when evaluating the packing, we will analyze only it possibilities and limitations, without reference to a specific type or design of the column.

The separation capacity of the packing is determined by the area of the contact surface between steam and reflux. In other words, the surface area of the wetted nozzle. Throughput – free from the nozzle and phlegm volume.

Both of these quantities can be determined by simple calculations. Let’s make them using the example of the popular nozzle SPN 3,5. The following characteristics of the nozzle will be required as initial data:

- weight of one liter (P) – 1050 grams;

- wire diameter (D) – 0,25 mm;

- if the nozzle was etched, it is necessary to take into account the etching depth (Ht) – 0,01 mm and the density of the material (Ro) – 7,9 g / cm³;

- let us take from the experimental data the value of reflux retention by one liter of nozzle (Vf) – 150 cm³.

1. In one liter of the volume of the column, the nozzle will take (cm³):

V=P/Ro;

V u1050d 7,9 / 133 uXNUMXd XNUMX cm³.

2. Pickled wire diameter is (mm):

Dt = D — Ht;

Dt u0,25d 0,01 – 0,24 uXNUMXd XNUMX mm.

3. Area of contact of steam with 1 liter of wet nozzle (cm²):

S = 20 * ((2V + Vf) / Dt);

S u20d 2 * (133 * 150 + 0,24) / 34667 uXNUMXd XNUMX cm².

4. Throughput of 1 liter wet nozzle (%):

Рsp = (1000 – V – Vf) / 10;

Рсп = (1000 – 133 – 150) / 10 = 71,7%.

Attaching the cost of the nozzle to the obtained characteristics is quite simple. We divide the price of the nozzle by the contact area and throughput, as a result, we get how much we paid.

An etched nozzle SPN 3,5 made of 0,25 mm wire costs about $ 33 per 1 liter from the manufacturer. This means that each square centimeter of the area of contact of steam with phlegm costs 0,1 cents, and each percentage of throughput costs 46 cents. But these numbers don’t say much on their own. Let’s compare a nozzle made of different thicknesses of wire, which has a different weight per liter.

| SPN easy | SPN average | SPN severe | On-load tap-changer | |

| Nozzle weight (g/liter) | 800 | 1050 | 1800 | 450 |

| Wire diameter (mm) | 0.2 | 0.25 | 0.4 | 0.24 |

| Contact area (m²/liter) | 3.5 | 3.3 | 3 | 2.1 |

| Throughput (%) | 75 | 72 | 62 | 79 |

| Price per liter ($) | 28 | 33 | 60 | 22 |

| The cost of 1 sq. cm contact area (cents) | 0.08 | 0.1 | 0.2 | 0.1 |

With an increase in the weight of one liter of packing, the cost of separating ability increases, and the same result is obtained for more and more money. In addition, the throughput drops, which means that the choke will come earlier and, in general, you will have to work at lower productivity.

At first it seems that the most profitable tap changer, the cost of its separating power is the same as the medium weight SPN, the problem is that the separating power is one and a half times worse.

Among the popular nozzles such as washcloths and SPN, SPN is the undisputed leader in terms of separating ability.

This is confirmed by the practical conclusions of distillers. For example, an experiment on the distillation of alcohol diluted to 40% on a half-meter side. After a small selection of “heads” sequentially and under the same conditions, 100 ml of alcohol were selected with a drawer filled with SPN, OLTC and washcloths. As a result, when using SPN, the selection strength was 96,4%, RPN – 94,4%, washcloths – 93,2%. This clearly illustrates the possibilities of these nozzles.

If a serious separation of SPN is generally predictable, then a large lag of washcloths from OLTC is not perceived at first glance and contradicts generally accepted dogmas. But the experiment is not complicated and everyone can easily repeat it.

If we talk about the cost of filling the column with packing, then there is something to be surprised about. In order to fill a 1,5-inch column with a height of 1 meter, you will need either a pair of washcloth wads and 1 liter of SPN nozzle worth 1750 rubles, or 10 tap-changer wads 40 cm long, with a total cost of 1250 rubles. For a two-inch column 60 cm high, having the same volume, you will need 6 tap changer wads in the amount of 1350 rubles. Is the savings as big as it is commonly believed? It’s more of a self-deception.

When analyzing the capabilities of the nozzle, one should not forget that despite the fact that the nozzle made of thin wire shows the best calculated results, it can be wrinkled. This will lead to local seals, which will become foci of choke or hanging phlegm.

The optimal wire diameter for SPN 2 is 0,2 mm, for SPN 3 – 0,22-0,25 mm, for SPN 3,5 – 0,25-0,28 mm.

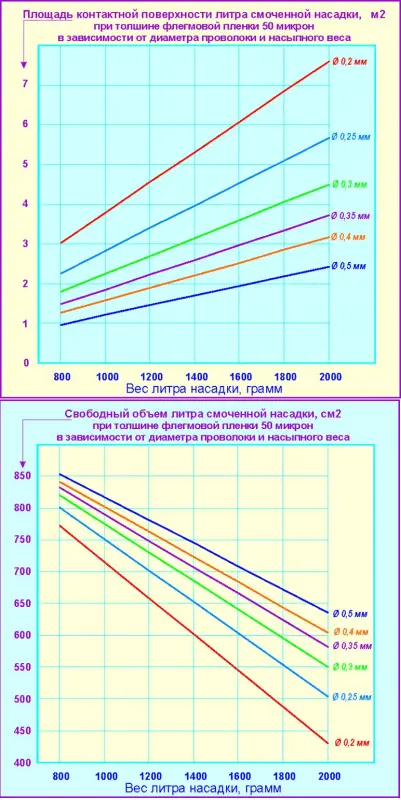

For example, let’s compare a packing with a density of 1600 g/liter and a wire thickness of 0,25 mm with a packing with a density of 1200 g/liter and a wire thickness of 0,35 mm. At first glance, the difference is not obvious, but using the graphs, we see that the first nozzle has a contact surface area of about 4,5 m2/ liter with a throughput of about 600 cmXNUMX2/liter. The second one keeps the indicators at the level of 2,3 m2/liter and 750 cm2/ liter respectively. It is obvious that the separating ability of the first nozzle is incomparably greater, the choice between them becomes clear.

In conclusion, it would not be superfluous to recall that one cannot trust the established dogmas about the cheapness and effectiveness of certain nozzles. You need to recalculate everything yourself, and not become a victim of paid advertising. We have provided a tool for this.

The author of the article is IgorGor.