Even after a long aging in barrels, cognac (whiskey) may remain light yellow, this is normal. To change the color, a natural dye made from burnt sugar is used – tint. The production of most French cognacs provides for its addition. Properly made caramel coloring does not affect the taste of the drink and does not cause haze. In turn, the technology for making sugar color is simple and easy to reproduce at home.

Caramel color is a natural food coloring that is resistant to changes in acidity and fading in the sun and is added to drinks to change color. The taste and (or) smell of caramel is felt only at very high concentrations or in low-alcohol drinks, such as beer.

Sugar color can be used not only in homemade cognacs or whiskey, it can be used to paint over moonshine, alcohol or tinctures without changing other properties (taste and smell).

sugar color recipe

Ingredients:

- sugar – 100 gram;

- bottled water – 130 ml;

- vodka (distillate, alcohol 40) – 100 ml;

- citric acid – 5-6 grains.

Citric acid makes the consistency of caramel more homogeneous, so it is advisable to add a couple of crystals.

Technology of preparation

1. Mix sugar and water in equal proportions (100 ml and 100 grams) in a saucepan.

2. Put on fire, bring to a boil.

3. As soon as foam appears and the bubbles become viscous, reduce the fire to the very minimum. After the water evaporates, the sugar will begin to darken, a caramel shade will appear. You need to constantly monitor the process so as not to burn the sugar.

The correct temperature for making caramel color is 190-200°C. If it is higher, then when the dye is added, the alcoholic drink will become cloudy or darken very much.

4. When the color of well-brewed, but not strong tea appears, remove the pan from the stove. It takes about 15 minutes from the moment the water evaporates to the desired color.

5. Cool to room temperature. Sugar should become hard.

6. Add citric acid and alcohol to the thickened caramel. It is advisable to dissolve the color in the same drink that is planned to be tinted.

7. Stir with a spoon until the alcohol base has dissolved almost all of the caramel. The process is long.

If the caramel does not dissolve, it can be put on fire for a couple of minutes and softened slightly. Remember that you are heating a liquid with a strength of 40%, do everything carefully!

8. Add 30 ml of water to the resulting syrup (there will be caramel residues at the bottom, this is normal) to reduce the strength of the color to 20-25 degrees.

Water is added right now, because according to the technology, burnt sugar must be dissolved in a liquid with a strength of 40-45 degrees.

9. When the color stops dissolving the caramel remaining at the bottom, pour the finished color into a storage container (preferably glass). Crush the rest of the burnt sugar and throw it into a container with color (optional).

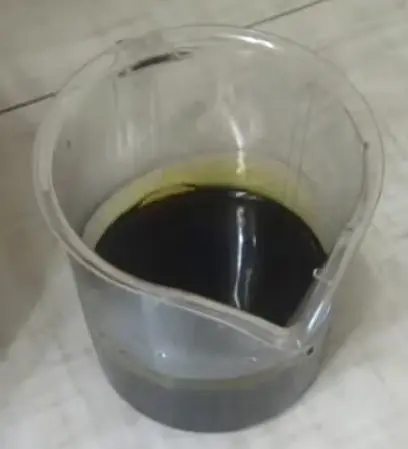

It turns out a sugar dye (concentrate) of a rich black color with a slight aroma of caramel.

You can store hermetically sealed color both in the refrigerator and at room temperature. Not a single microorganism processes caramelization products, so the sugar dye practically does not deteriorate.

There are no clear proportions for adding color to distillates and alcohol, the amount depends on the desired color. I advise you to use the dye a couple of drops per liter of drink, mix, wait 3-5 minutes, and then tint again if you wish.

The full technology is shown in the video.