This step-by-step instruction is just one of the methods of distillation on a distillation (RD) or mash (BK) column, having mastered which you can get a highly purified product. However, for fruit, berry and grain distillates there are technological nuances, without knowing which, instead of a flavored drink, there will be pure alcohol. Each type of nozzle has its own characteristics. Use the proposed method as a start for studying the operation of columns, training on sugar mash, or knowing that you will end up with rectified alcohol or a drink close to it.

Initial conditions

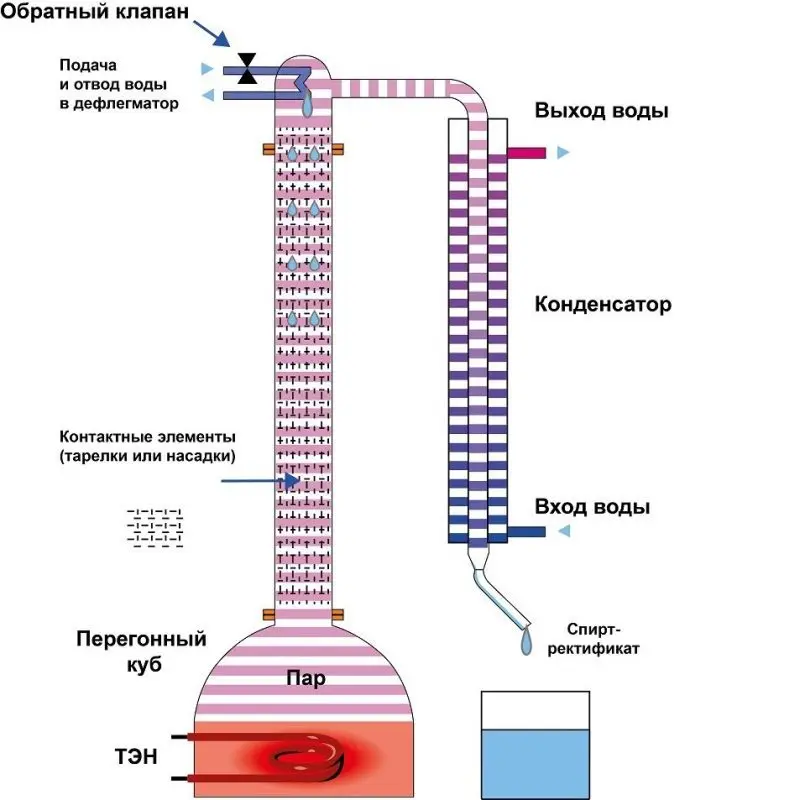

Raw alcohol is available – sugar mash distilled on a conventional distiller (moonshine still) and properly prepared equipment – RK or BK. In this case, the procedure for working on different types of columns is almost identical, and the differences are described in appropriate places in the instructions.

Technology of home distillation on RK and distillation on BC

1. Fill the cube with raw alcohol no more than 3/4 of the height, leaving at least 10-12 cm of the vapor zone. However, it is also impossible to fill in too little, so that at the end of the distillation process, when there is almost no liquid left in the cube, the heating elements do not emerge (do not become bare).

The strength of the cubic bulk should be about 40%. This value is related to the minimum phlegm number required to achieve the selection of a given strength. With an increase in the strength of the bottom bulk, the minimum reflux ratio decreases non-linearly, reaching a minimum at a strength of about 45%. Therefore, if you start the process with a fortress of 60%, then you will have to reduce the phlegm number up to 45% of the fortress, and then increase it as the distillation residue is further depleted in alcohol. That is, first increase the selection from 60 to 45% of the cubic strength, and then reduce it. As a result, rectification will not only be more difficult to manage, but will also take longer.

2 Turn on the heater at maximum power and bring the raw alcohol to a boil. The optimal heating element power for overclocking is 1 kW per 10 liters of bulk, then the time to boil is 15 minutes for every 10 liters of bulk.

3. Shortly before the start of boiling, at a temperature of 75-80 ° C in the cube, turn on the water supply. After the start of boiling, reduce the heat to operating power. If the operating power is not yet known, reduce to a level below the rated power by 200-300 watts. Adjust the water supply so that the steam is completely condensed in the dephlegmator. The outlet water should be warm or hot. The column began to work for itself.

4. Monitor the values on the thermometers in the column, wait for the readings to stabilize.

5. Determine the operating power of the column. To do this, after stabilization of temperatures, check the pressure in the cube. You will need a pressure gauge up to 6000 Pa (0,06 kg / sq. cm, 400 mm water column), or a U-shaped differential pressure gauge, a pressure gauge from a tonometer will also work (if nothing else is found).

If the pressure is stable and does not increase, increase the heating power by 50-100W. The pressure in the cube should rise and after 5-10 minutes stabilize at a new value. Repeat this operation until the pressure ceases to stabilize and continues to increase, for example, after 20 minutes the increase continues. Remember the current readings – this is the power of the choke.

If there is a 50 mm column and a SPN 3,5 packing, then the last non-increasing pressure (in mm of water column) will be approximately equal to 20% of the column height in millimeters. If the pressure is 30-40% of the height of the column, this means that the phlegm has hung, and the process of choking continues. With a less dense nozzle with less holding capacity, the power of the choke will be higher.

If there is no pressure gauge, they are guided by the sounds of the column – when choking, the column may begin to sway, gurgling, increased noise is heard, and spontaneous emissions of alcohol through the communication tube with the atmosphere or into the refrigerator when steam is taken are also possible. For the first time without experience, it is difficult to determine the choking of the column, but it is possible.

After determining the power of the choke, turn off the heat and wait a few minutes for the phlegm to glass into a cube. Turn on the heating at a power 10% less than the choke. Wait for stabilization of temperatures and pressure in the cube. If everything is in order, then this will be the working capacity of the column.

If the operating power is much lower than the nominal, this means that the packing or packing support elements are not properly packed in the column: the packing is too overpacked, possibly tangle, there are pockets of reflux concentration, where the steam stops it, flooding the column. In this case, you need to disassemble the column, pour the nozzle, straighten the tangle, then reassemble and repeat the setup process.

The operating power of the column is determined once. In the future, the obtained value is used constantly, occasionally making adjustments.

With a properly selected working power, the pressure in the cube will be the same every time. It does not depend on the diameter of the column and usually amounts to 3,5 – 150-200 mm of water for the SPN packing. Art. for each meter of nozzle height, for SPN 4 – 250-300 mm of water. Art., for other nozzles, the value will be different.

When looking for operating power, you can also focus on the following practical data: for an etched heptagonal SPN 3,5, the operating power in watts is approximately equal to 0,85-0,9 of the pipe cross-sectional area in millimeters. If SPN 4 is used, the coefficient increases to 1,05-1,1. For less dense nozzles, the coefficient will be higher.

6. After stabilization at operating power, let the column work for itself for 40-60 minutes.

7. Set the selection of “heads” at a rate of 50 ml/h for 40 mm columns, for 50 mm – 70 ml/h, for 60 mm – 100 ml/h, for 63 mm – 120 ml/h. Provided that SPN is used.

The time of selection of “heads” is determined based on the bulk volume: 12 minutes (0.2 hours) for each liter of 40% raw alcohol. It must be remembered that this is not distillation in a conventional apparatus with a coil – in the columns, fractions are separated and they are sequentially removed for selection in a concentrated form.

Recommendations such as 3-5% of absolute alcohol are average values, but no one has canceled them, and precise control of the end of the selection of “heads” is done, guided by the smell of the exit. It should be remembered that the time and speed of the selection of “heads” are not related quantities. If you select “heads” at twice the speed, they will simply turn out in a less concentrated form.

General principle: during the selection of any fraction, it is impossible to take more from the column than enters the selection zone. This will prevent violation of the separation of fractions along the height of the column.

8. Changing the rate of extraction is only possible by adjusting the water supply to the reflux condenser for columns with steam extraction upstream of the reflux condenser. If the column is with liquid extraction, then just a selection valve.

The heating power must always be constant, this ensures the stability of the amount of steam supplied to the column and the operation of the column as a whole.

9. Select headrests – this is second-class alcohol, slightly contaminated with head fractions. Its amount is equal to 1-2 volumes of alcohol held by the nozzle in the column (150-500 ml). In fact, the nozzle is washed from the remnants of the “heads” and the intermediate fractions accumulated in the column. To do this, the selection is set at 1/3 of the nominal (about 500 ml/hour). Alcohol of the second grade is suitable for re-distillation.

10. Go to the “body” sampling: set the initial sampling rate equal to the nominal or slightly higher. The rated speed (ml/h) is numerically approximately equal to the operating heating power (in W). For example, if the working power is 1800 W, then the initial rate of selection of the “body” is 1800 ml per hour. By the end of the selection, the rate is reduced to 600 ml/hour,

11. Control the process according to the readings of thermometers and the pressure in the cube. There are several methods. The simplest is to navigate by the temperature difference between the lower (20 cm from the bottom of the nozzle) and the middle (at half or 2/3 of the column height) thermometers. After the start of the selection of the “body”, the difference in these readings should not change by more than 0,3 degrees. As soon as the difference increases by more than the accepted value, it is necessary to reduce the selection rate by 70-100 ml.

Special cases: if there is only one thermometer, proceed in the same way, focusing on the change in its readings. For the lower – a change of 0,3 degrees, for the upper – 0,1 degrees. This is a less accurate method, as it is sensitive to changes in atmospheric pressure.

If there are no thermometers in the column at all, they are guided by the change in temperature in the cube – they reduce the selection by 6-10% after the temperature in the cube rises by each degree. This is a good method that allows you to get ahead of the rises in the column in terms of temperature.

12. After the selection of half of the “body”, more and more often it is necessary to reduce the speed of selection. When the temperature in the cube rises above 90 °C, fusel and other intermediate impurities leave the cube and accumulate in the nozzle. To cut them off more clearly, you can let the column work for itself for several minutes before reducing the selection, then resume the selection after the temperature difference returns to its previous level, naturally, reducing the selection rate. This will make it possible to more clearly cut off the “tails” by creating an alcohol buffer in the sampling zone.

13. When the selection is reduced by 2-2,5 times in relation to the initial one, the temperature regularly leaves the operating range, while the temperature in the cube is 92-93 °C. These are signals for the BC that it is time to move on to the selection of “tails”. On the RC, due to the greater holding capacity, with less than 20 packing volumes, the selection can be continued up to 94-95 ° C, but the process is often stopped, saving time and nerves.

Change the container, set the selection rate to about half or 2/3 of the nominal. Although these are “tails”, but you need to try to take a minimum of impurities. Sample up to 98 °C cubed. “Tails” are suitable for the second distillation.

14. Rinse the column. After selecting the “tails”, let the column work for itself for 20-30 minutes, during which time the remaining alcohol will collect at the top, then turn off the heating. Alcohol, flowing down, will wash the nozzle.

Also, periodically you need to steam the nozzle, removing the remnants of fusel oils. This can be done by driving the raw alcohol “dry”, then continue the selection at a decent speed until an odorless distillate comes out. The second method is to pour clean water into the cube and steam the column.

The author of the article is IgorGor.