Contents

Often, when distilling thick mash, the thick burns, badly affecting the aroma and taste of the drink. To prevent deterioration of the quality of the distillate, steam distillation of the mash allows. Making a steam generator at home is relatively simple – you will need another container (pressure cooker, distillation cube, can), connecting hoses and a gas supply pipe.

Scope of application of the steam generator

Any mash can be steamed, however, due to the additional time and energy involved, it is advisable to use this method for the first distillation of thick brews – usually all grains and some fruits from overripe raw materials with a high pectin content, such as apple or apricot. Steam distillation is also used for chacha and other moonshine from cake.

To speed up the process, some moonshiners drain the liquid part of the mash separately and distill it in the traditional way, and use the steam generator only for thick.

Advantages of steam distillation:

- the mash that has won back is not drained from the sediment and is not clarified;

- you can get alcohol in the thick, which is usually filtered and disappears;

- avoids burning and deterioration of the quality of moonshine;

- during distillation, less harmful impurities are “welded”;

- does not affect the organoleptic properties of the drink in any way, is the most gentle method of heating the mash;

- suitable for moonshine stills of any design.

Disadvantages:

- one more container is required, which will be a steam generator;

- the distillation time increases (more than 3 hours from the moment the mash boils);

- since alcohol vapors are diluted with condensate, the yield strength decreases, for example, if when heated by a heating element, the maximum strength in the jet is 68%, then during steam distillation it will be 50% (calculations are approximate and depend on the design of the distiller);

- Due to the high pressure in the steam generator, the danger of operating the device increases.

The principle of distillation of braga by steam

In the classic scheme of a moonshine still, a steam generator is a container filled with water, which is installed on a stove (another source of heating) and connected through connecting pipes and a bubbler to the bottom of the distillation cube with mash (it does not heat up separately). In turn, the distillation cube is connected to the refrigerator of the moonshine still.

After the water boils, the formed steam under pressure through the bubbler enters the cube and heats the mash. Vapor bubbles move from bottom to top, cause boiling inside the mash and the separation of substances into fractions. As a result, alcohol begins to evaporate, which moves to the surface of the mash. On the surface, the bubbles of steam and alcohol burst and mix, forming a vaporous water-alcohol mixture, which rises to the refrigerator (distiller), where it condenses.

The design of the moonshine still and the distillation scheme remain the same, only one more container of water is added.

How to make a steam generator for mash

As a container for heating water, you can use a pressure cooker or alembic. The main requirement is that the container must be airtight and withstand high pressure so that the steam passes through the steam line, and does not seep through the lid. The capacity (volume) of the steam generator is usually 30% less than that of a mash cube. After sealing the lid, a saucepan or can will also work.

Attention! Since we are dealing with thick mash, for safety reasons, there must be blast valves on the lid of the steam generator and the main distillation cube, which will bleed excess pressure if the connecting pipes become clogged with thick, and this happens.

A fitting is also cut into the cover of the steam generator for connection to the steam pipeline.

For the steam line, use a silicone hose or a corrugated gas pipe. In order to reduce heat losses and increase the speed of distillation, it is desirable to install thermal insulation on the surface of the steam pipeline that can withstand temperatures of +100 °C.

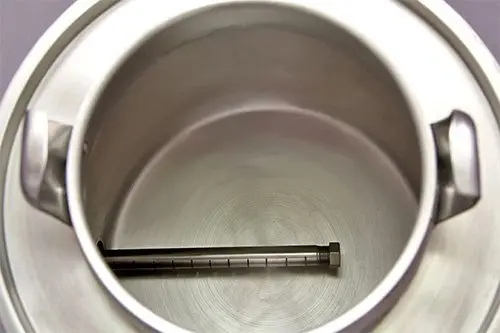

For the bubbler of the steam generator, a metal tube is suitable, on one side of which slots are made. The length of the tube should be slightly less than the diameter of the bottom of the distillation cube with mash. The bubbler is installed in the cube through the drain valve for the bard with the slots down so that the steam is first reflected from the bottom, and only then begins to heat the mash. If there is no drain tap, you will have to make a hole near the bottom.

The result should be a scheme: a steam generator – a distillation cube – a steamer (optional) – a refrigerator (distiller) – a receiving container for moonshine.

Distillation Tips

It is recommended to fill the cube with mash by 50-60%, since during the distillation the volume of liquid in the cube will increase by 20-30% due to steam, and for the normal formation of alcohol vapors, an additional 10-15% of the free volume is required.

The optimal amount of water in the steam generator in relation to the mash is 8:10 (8 liters of water per 10 liters of mash). The minimum amount of water is 6:10. The steam generator is filled to 70-85% of the volume.

The heating power supplied to the steam generator must be as high as possible.

In case of clogging of the steam pipeline, turn off the heating and wait for complete cooling before disassembling the apparatus, the excess pressure must be relieved by the valves. Opening a hot steam generator is dangerous!