Contents

A flat roof for a gazebo is the most financially advantageous design. It facilitates fast, and most importantly, safe installation at height. But in terms of drainage quality, it is significantly inferior to other types of roofing.

Types of roofs and tips for beginners

This is one of the most important parts of the structure, designed to withstand wind loads. To this end, about 58% of summer residents prefer a pitched roof. The main elements here are the crate and rafters. A variety of design options contributes to the solution of not only ordinary, but also complex design problems.

In choosing the optimal type of roof for a gazebo, the first thing to pay attention to is a shed design. It provides reliable protection against precipitation and wind, and in conditions of a large area of u3buXNUMXbthe slope can withstand XNUMX-meter snowdrifts. The minimum cost of roofing materials and the possibility of installation without special equipment are among its other advantages.

The advantages of the double-sided option include:

- the presence of dense triangular surfaces that provide better protection of structures from rain with hail;

- the optimal angle of inclination contributes to high-quality drainage, and as a result – the long-term use of slate and soft tiles;

- unlimited possibilities in the use of space under the roof;

- good maintainability;

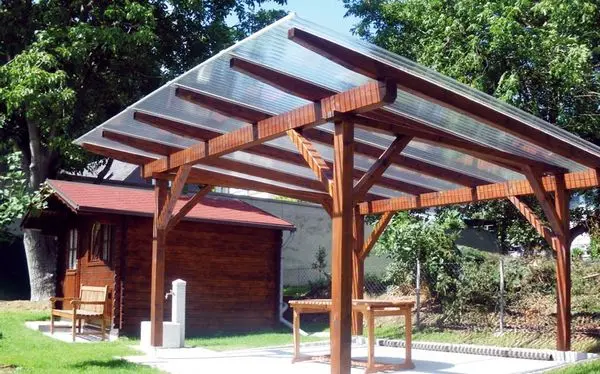

- a wide choice of roofing materials – from a flexible covering to transparent polycarbonate.

A dome-shaped roof with a minimum weight has greater strength than a gable roof. In the conditions of small-sized buildings, it can be done by hand in less than a day. To work, you need oak beams with a section of 100×50 mm, connectors, a profile pipe and a welding machine. Laying heavy slate, a “live” canopy, and even more so a ceramic coating, is inappropriate in this case. In order for a lightweight structure to last at least 20 years, it is better to cover it with waterproof ondulin.

In gazebos with barbecues, it is acceptable to use fire-resistant structures with profiled sheets in the composition. The minimum snow load here often exceeds 150 kg per 1 sq. km. m roof.

Video “How to build a gazebo with your own hands”

From this video you will learn how to properly build a wooden gazebo at their summer cottage.

Materials

A competent choice of coatings depends not so much on the price as on their resistance to mechanical stress. It is equally important to take into account the level of load on the supporting structures and the physical and chemical properties of products. First of all, we mean the indicators of density, strength, hygroscopicity and, of course, refractoriness. For example, if they plan to build a gazebo with a barbecue in the country house, the installation of a flammable roll roof is out of the question. It is better to buy polycarbonate. The material has good flexibility, due to which strong arched structures are obtained. And besides, it does not support combustion.

Supporters of natural products can be advised ceramic tiles. Most often it is laid on a wooden base. To ensure that the roof does not let water through, it is important to ensure that the grooves are firmly fixed. If the tiles are laid incorrectly, the roofing cake will be filled with liquid after the first rain, and the snow retainers will completely cease to perform their functions.

Profiled sheeting

Profiled leaves with a thickness of at least 8 mm are the best option for arranging a round roof. The material lends itself well to processing, does not deform, and due to its light weight it contributes to safe installation at any height. In work, it is better to use products marked “NS”, through which it is possible to close the slope from the intersection of several planes to the very cornice within 3-4 hours.

For laying colored sheets with an overlap, you will definitely need self-tapping screws with rubber seals. The size of fasteners depends on the height of the wavy part of the sheet. Based on the area of uXNUMXbuXNUMXbthe roof, you can determine their exact number.

Tiles and slate

Step-by-step installation of the bituminous tile most demanded in our time looks like this:

- A sheet pile or plywood is placed on the prepared crate – this is the best base for a flexible coating.

- As a waterproofing, a special lining carpet is used. It can be attached to the base with building glue.

- Lay down the starter sheet.

- Stitch the top and bottom of the materials with nails.

In the presence of a long slope, installation work begins from the central point of inclination. Slate is laid from left to right, and nails are driven in at the highest point of the wave.

Polycarbonate

Roofing made of polymer plastic performs not only a protective, but also a decorative function. This is facilitated by a rich color range of products. The advantages of the material include light weight, easy installation, good light transmission and corrosion resistance.

Polycarbonate is one of the fragile products, so it is better to use professional tools in your work. For the installation of a multifaceted roof, monolithic canvases with a thickness of at least 12 mm will be required. In the case of a shed type of roof, light honeycombs are rectangular in shape.

Reliable fixation of the panels is facilitated by self-tapping screws with sealing washers.

Soft roof

The material provides XNUMX% rain protection. This is facilitated by its structure: stone granulate, fiberglass, bitumen and protective film. Other advantages of soft roof experts include a high level of sound insulation, the possibility of minor repairs and easy installation.

Of the shortcomings, the first thing to mention is poor resistance to high temperatures and a low level of thermal insulation. For self-laying a bitumen-rolled roof, you will need end strips, roofing nails, mastic, a hammer and sealant. In installation work, it is better to use sheets from several packages. So you can achieve a uniform shade within 8 and even 20 squares.

Other types

If it is important for the owners to emphasize a certain exterior style, it is more logical to choose other materials:

- Straw pre-treated with flame retardants. At the same time, the thickness of the coating should not be less than 40 cm. For laying the coating, sharp games, wire loops and self-tapping screws are needed.

- Reeds, contributing to the natural ventilation of the premises. In summer, such gazebos remain cool, and warm in winter. Screws are used to install the battens, and it is better to fix the sheaves with wire.

- Wooden planks without connecting locks. They are laid with small gaps horizontally or vertically.

- Waterproof tarpaulins are attached with construction staples and nails.

- Sun protection membranes made of PVC components. They withstand temperature fluctuations well, reflect up to 65% of natural light and do not ignite. Building glue can contribute to better sealing of joints.

- Maintenance-free copper sheets. To avoid premature destruction of the metal, it is better to use galvanized fasteners.

How to make a roof

First you need to “plant” the Mauerlat on the brackets. In wooden arbors, the function of this element is performed by a crown of timber. Then rafters are attached to it, and the finished frame is attached to the box of the building.

To reduce the 5-meter span of the rafters, you need to install racks, and then connect the supporting structure to the ridge run. Metal plates will help with this.

Before making the crate, you need to prepare a layer of waterproofing from a waterproof membrane. Installing a ventilation system is an equally important procedure. The viability of roofing materials depends on it.

After laying the coating, the roof should be insulated with mineral wool at least 180 mm thick.