Contents

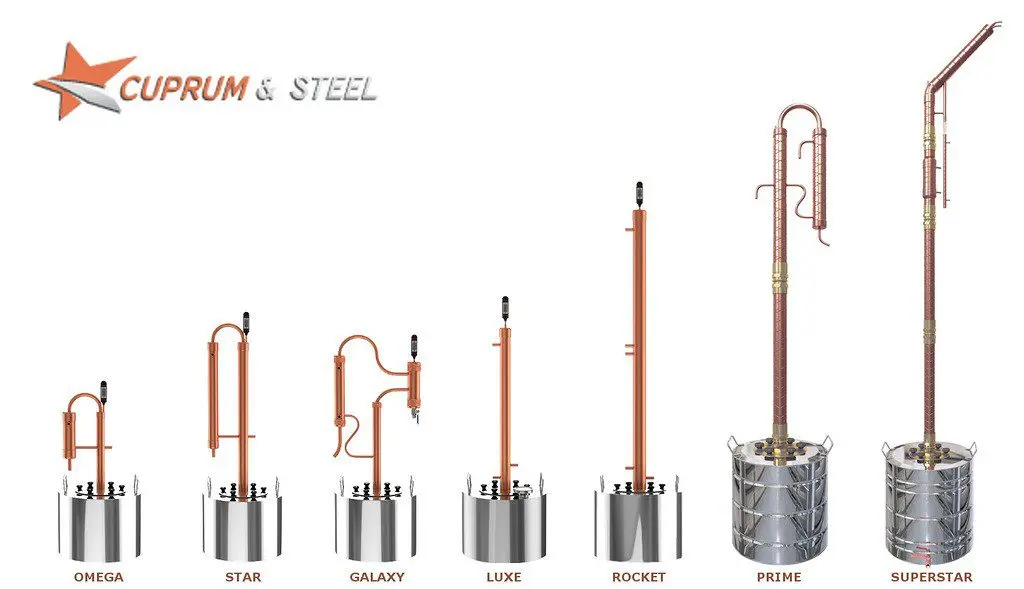

Cuprum and Steel produces seven models of equipment with various modifications according to the diameters of the pipes used and the capacities of the refrigerators. In this review, we will give a detailed description of the Rocket line, but we will also touch on the rest (Omega, Star, Galaxy, Deluxe).

Stills

All devices are equipped with simple and unpretentious cubes from 12 to 50 liters, made of AISI 430 stainless steel. The tanks have a flat bottom and are suitable for all types of heating. The neck diameter of 11,5 cm allows you to stick your hand into the cube and somehow wash it. A thick 5 mm silicone gasket under the lid is also good.

The lid is curved towards the tank in the form of a saucer, which allows it to be reliably sealed with 6 lambs. The lambs also deserve praise, as they have a plastic heat-insulating coating.

Nothing more good can be said about the cube: the bottom is thin 1,5 mm, there is no blast valve, there is no tap to drain the stillage. The thermometer is included in the kit only as an additional option, and even then – only a primitive bimetallic display is offered with an accuracy class of 2,5 and a scale division of 2 degrees, which, due to low accuracy, is of no practical use.

It is difficult to evaluate the geometry of the cubes, since the manufacturer publishes sizes on its official website that do not correspond to volumes, but most likely to reality. For example, for a cube of 60 liters, “Cuprum and Steel” indicates a diameter of 23 cm and a height of 30 cm, while for the rest of the cubes the same geometric dimensions are named, which looks fantastic.

Brief description of the entire range of “Cuprum and Steel”

In the offered range there are many simple and honest distillers of completely different performance. For example, the Omega and Star lines are ordinary column-type moonshine stills with a cold finger at the bottom of the column.

The Galaxy line, despite its futuristic appearance, can disappoint any home distiller with a small refrigerator and, as a result, low productivity. Suffice it to say that cool moonshine can only be obtained with a heating power of 1,2 kW, while the extraction rate is up to 1,5 l / h, but if you raise the power to 2 kW, then the temperature of the distillate will increase to + 40-42 ° C, and productivity will increase slightly to 1,8-2 l/h. These are reviews of real users, and 4,5 l / h declared in advertising.

But the real finds for lovers of the exotic are the “Deluxe” lines, modestly called the mini-branch column and “Rocket”. Moreover, the latter, according to the manufacturer, is nothing more than a mini distillery with an elongated distillation column. The declared productivity of the most powerful apparatus of the Rocket 42 line is 5 l / h. This miracle of technology needs to be disassembled in detail.

Characteristics of the apparatus “Rocket”

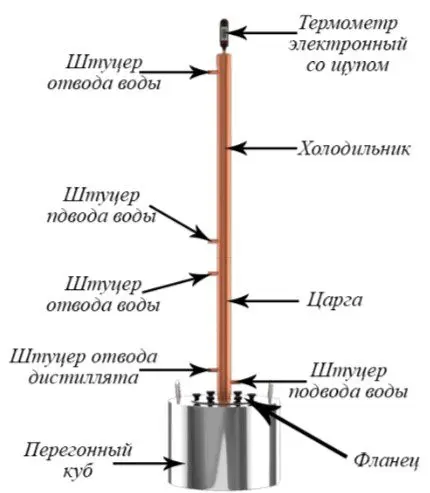

The Rocket apparatus has a very bizarre design. The column consists of two jacket coolers 34 cm and 35 cm long, interconnected by a thread and inserted into the column by a steam pipe with a diameter of 2 cm and a total length of 64 cm. The pipe also has two parts.

Yes, indeed, an elongated distillation column – as much as 64 copper centimeters instead of the minimum required for rectification of 1-1,5 m!

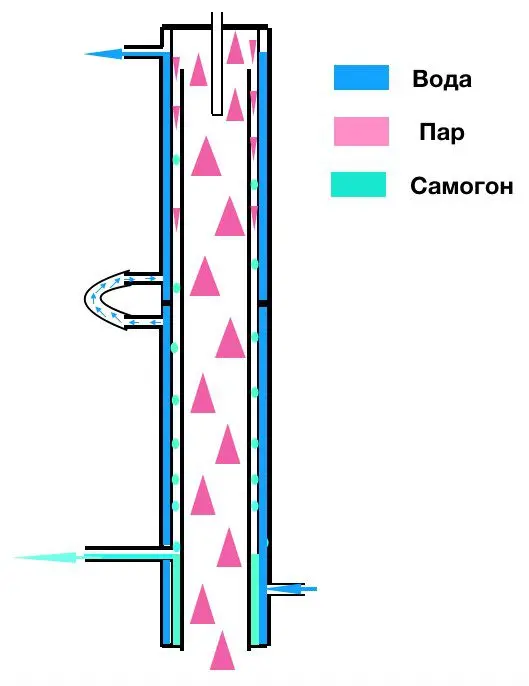

Steam enters the inner tube of the column, then rises to the very top, then goes down through the annular gap between the steam tube and the inner surface of the jacket coolers. On the way, the steam condenses, as a result, the moonshine flows down the column, where it flows out through the distillate selection fitting.

This is such a clever scheme. What did the designers want to achieve? Apparently, they expected that the inner tube, cooled by the flowing phlegm, would work as a partial condenser, purifying the vapors from heavy-boiling constituents. But 64 cm of a tube with a diameter of 2 cm is not enough for this. Yes, there will be a slight strengthening, but very minimal.

The problem is that the higher the steam rises, the hotter the steam pipe gets. A small amount will condense on the first centimeters, but the rest of the steam will slip further, where it will meet with an increasingly hot pipe, and with minimal losses will pass to the very top. Talking about purification, and even more so to the level of rectified alcohol, is not serious.

In reality, the Rocket Cuprum&Steel column will work like a regular moonshine still with a little reinforcement, and the payment for the “original design” will be deplorably low performance. No 5 l/hour!

As tests have shown, during the test distillation of mash with a heating power of 2 kW, the column produced a productivity of 0,7 l / h of 55% moonshine with a temperature of about +26 ° C. At the same time, it was not possible to select the “tails” at all because of the jacket cooled by water. At a certain stage, the heat loss equalized the heating power, as a result, the distillation simply stopped.

During fractional distillation of raw alcohol with a strength of 20%, the “head” was taken at a power of about 1 kW. When heated to 2 kW, the productivity was still the same 0,7 liters per hour. The strength of the distillate is 77%. As you can see, the additional reinforcement is insignificant. In the case of distillation on a classic distiller, about 70% of the fortress would be obtained, and by placing a couple of plates, you can reach up to 85%. The conclusion suggests itself that in terms of the degree of strengthening, the entire structure corresponds to one cap plate.

A reasonable question may arise: what will happen if we increase the heating power? Then the steam pipe will become even hotter, the heat loss will decrease even more, and the amount of phlegm formed will also drop. The idea of cutting off fusel oils will remain only a dream, and the output product will become even closer to ordinary moonshine. Performance, however, will increase somewhat, but it will still not work to catch up with the classic device in this indicator.

Apparently, for Cuprum & Steel, the main thing was to declare that the Rocket apparatus belongs to the class of distillation columns. Then you can set a sky-high price and demand will be higher. Calling this product “Rocket” with its very low performance is simply ridiculous.

Cuprum and Steel’s “Rocket” devices have nothing to do with distillation columns, as they do not implement heat and mass transfer technology. These are just column-type distillers, and of dubious design.

Harm of the device “Rocket”

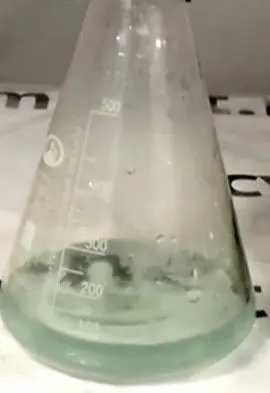

A common drawback of all Cuprum & Steel devices is copper refrigerators. When an amateur moonshiner makes a product for himself, it is his right to get sick and die from something. But when a manufacturer offers the market a product that produces moonshine that is hazardous to health, this already borders on a crime.

It is impossible, even having ambiguous opinions about the dangers of the formation of copper oxides in the refrigerator and getting into the selection of copper oxides, to interpret them in favor of one’s own pocket. If there is the slightest doubt, you need to remember the wise phrase from the Hippocratic oath: “do no harm”!

Doubts about whether copper oxides are formed at all in the refrigerator are easily resolved. In the photo, the product obtained specifically from the “Rocket” from “Cuprum and Steel” during the test distillation. What a nice blue color…

More than once, studies have been carried out on the organoleptic and efficiency of removing sulfur compounds when using copper in parts for beer columns. The conclusions indicate that the greatest effect in the distillation of mash copper gives in the manufacture of columns and packings from it, that is, it is necessary to use copper in the vapor zone, and with a maximum contact area.

With repeated fractional distillation, the cube and column come out on top. The refrigerator does not give any practical effect. These conclusions are consistent with the opinion that has been established in the leading forums about the feasibility and usefulness of using copper for parts of a moonshine still in ascending steam flows.

Phlegm washes away oxides from such parts and flows back into the cube, and since copper oxides are not volatile, they will no longer be able to get into the selection. For refrigerators, it is recommended to use neutral stainless steel. It is unforgivable for a professional manufacturer of copper devices not to know about all this.

However, all Cuprum and Steel apparatuses have copper refrigeration and successfully send all new portions of oxides into the glasses of their owners. Maybe it’s time to remember that the name of the company contains not only “Cuprum (Copper)”, but also “Steel (Steel)”?

conclusions

Summing up the results, we have to admit that moonshine stills of the Rocket model range are not only low-productive, but also dangerous to health. Their use must be discontinued immediately. Modernization and modifications are not possible.

The review was conducted by IgorGor.