Contents

Safety, explosive, bleed valve. As soon as it is not called, mixing various functions and purposes, without looking at the design and characteristics. Moonshiners are still arguing hoarsely about the need for a safety valve, despite the huge number of accidents with dire consequences. It is enough to type in the search engine: “explosion of moonshine still” to seriously think about this problem.

Theory

An alcohol-containing liquid boils in a cube. If the steam outlet is blocked, the pressure will rise. At the same time, the boiling point of the liquid will also increase. Energy generously pours into the cube and accumulates every second, but this process is not endless. Sooner or later, mechanical depressurization of the cube will occur. For example, he will break the clamp, and the lid will shoot at the ceiling. If that was the end of it, then there would be nothing to discuss. Easy repair of the kitchen, replacement of the chandelier – the affairs of life.

However, after depressurization, the pressure in the cube drops sharply, as a result, all the accumulated energy is released and leads to a sharp, explosive boiling of the entire volume of the bulk (alcohol-containing liquid in the cube). The resulting alcohol vapor flies out of the cube, along the way taking out a fair share of the bulk.

Danger in numbers

For example, in a cube there were 40 liters of raw alcohol, the excess pressure that tore off the lid was only 0,5 atmospheres, which is close to reality. As a result, about 10 liters of boiling raw alcohol will fly out of the cube and flood everything around, scalding people and pets. About 10 more liters will turn into steam and instantly form an explosive concentration of alcohol vapor in the room. If the moonshiner is a loser, neglecting the elementary safety rules, and worked on an open fire, the explosion will be immediate.

If the distiller was friends with his head and worked on closed heat sources, for example, heating elements, but was confused and decided to quickly unplug the plug from the socket or simply flip the switch, the explosion will occur immediately after that from a small spark that slipped when the contacts were opened.

Well, if the owner was not in the kitchen at that moment and his not scalded body retained the ability to think, then he will slowly and carefully open all the windows, create a draft and, possibly, avoid more serious consequences.

The consequences of a volumetric explosion are very impressive – this is a wall removed to the neighbors, a balcony block that has flown across the road. There are other miracles as well. When nothing happens directly in the kitchen, and the explosive mixture ignites from a spark in the next room and destruction will occur there.

To prevent this scenario, a bleed valve is needed. Alcohol vapor is not a gas; when bled off, it will not accumulate to an explosive concentration. Once in the air, alcohol vapors immediately begin to condense and settle on walls, windows, and floors. Fly into the hood or window. It will stink, warning the owner of an unusual situation. The probability of an explosion becomes much less, although this does not insure against a fire.

As statistics show, large diameters of columns do not at all relieve their owners from the risks of working with flammable and explosive liquids. This is the nature of our hobby.

Relief valve parameters

The main danger in the distillation of moonshine is not at all in the mechanical destruction of the parts of the apparatus, but in the creation of an explosive concentration of alcohol vapors due to a sharp depressurization of the cube.

In practice, this determines the requirements for the safety valve.

During the second distillation, the pressure in the cube is 500 mm of water. Art. is considered emergency, because it indicates the flooding of the column. But should it be prevented with a bleed valve? Definitely not.

If the valve will bleed at 400 mm w.c. Art., then on the one hand the column will not sink, but on the other hand we will get just an imitation of its normal operation. As soon as the valve works, the phlegm will collapse down, violating the careful separation into fractions. As a result, the output will be ordinary fortified moonshine, and not a distillate purified from impurities. The valve must not interfere with or contradict the technological processes taking place in the apparatus.

Let’s take another example. With an increase in pressure in the cube, a thermometer can shoot and depressurization occurs – well, it’s good, again, it bleeds the excess without the threat of an explosion. A valve to prevent this event should not be installed, it should be treated as a backup system.

But if the lid is torn off on a saucepan or pressure cooker, the exhaust will be instantaneous. Clamps, depending on the quality of workmanship, can fly off at a pressure of 1 atm. This is already a matter of control. In addition, as shown above, depressurization even at an overpressure of 0,5 atm. capable of creating an explosive concentration of vapors in the room. Here is another point.

Conclusion: in order not to interfere with the setting of the column, the safety valve must operate at a pressure of at least double emergency – 1000 mm of water. Art. = 70 mmHg Art. = 9,8 kPa = 0,1 bar. The closer its operation to 0,5 bar, the more severe the consequences in case of failure. That’s the whole logic.

Safety valves from different manufacturers

Let’s start with the most illiterate and have no idea about the parameters of the processes in the device. Such manufacturers install blast valves from pressure cookers on their cubes. Note – not pitting, namely subversive or, in other words, emergency.

This cheap valve actually works at a pressure of 1,2 to 1,5 atm. – the line of last hope for the pressure cooker. It is clear that for the purposes of distillation and rectification it is useless, since a broken collar and an explosion are possible up to the threshold of its operation.

The working bleed valve of the pressure cooker looks like this, it should not be confused with the emergency one.

The working valve in the pressure cooker maintains an excess pressure of 80-110 kPa (0,8-1,1 atm.). The safety valve is activated when a pressure inside the pressure cooker is 50 kPa higher than the working one (i.e. at 1,6 atm.), which can occur if the working valve is clogged. The actuation of the safety valve allows the release of steam from the pressure cooker and makes it safe during operation. But not in our case. Its characteristics, of course, are closer to the desired range, but not by that much.

The emergency valve can be tried to be redone. To do this, you need to disassemble it, throw away the spring and the red ball. In place of the ball, install a weight weighing about 36 grams. This will reduce the response threshold to 700-1000 mm of water. Art., but even this alteration does not guarantee the normal operation of the valve. The stem is easily warped and the valve does not close, and after a dozen operations, a design not intended for this mode is easily contaminated in the area of the silicone sealing ring and ceases to be airtight. As a temporary way out of the situation, this alteration has the right to life, but not for permanent use.

The use of safety valves from heating systems and other water heating equipment is faced with the problem of inability to adjust the response pressure to the desired value.

As a rule, for these systems, pressure above 1,5-8 bar (150-800 kPa) is considered emergency. For home brewing, these are absolutely prohibitive values. The principle of their operation is simple, but even replacing the springs with less rigid ones often does not give the desired result, since the valve simply ceases to press hermetically against the seat.

Therefore, thinking equipment manufacturers were forced to develop their own valves that operate at a pressure of about 900-1000 mm of water. Art. (70 mm Hg).

These are fairly simple valves of low cost, about 350 rubles, with spare membranes priced at 40 rubles. They mount on a standard ½” threaded fitting.

How to make a safety valve for a moonshine with your own hands

Let’s take a closer look at the design of the valve.

We take the old hose from the shower or flexible hose and remove the nuts from it. We complete with a fluoroplastic gasket and a silicone gasket. The gasket can be taken from a beer cork. It remains to collect everything. True, it will differ from the original in a washer with a groove under the membrane. The thickness of the membrane is 1 mm, and the grooves are 1,3 mm, it will work with careful installation.

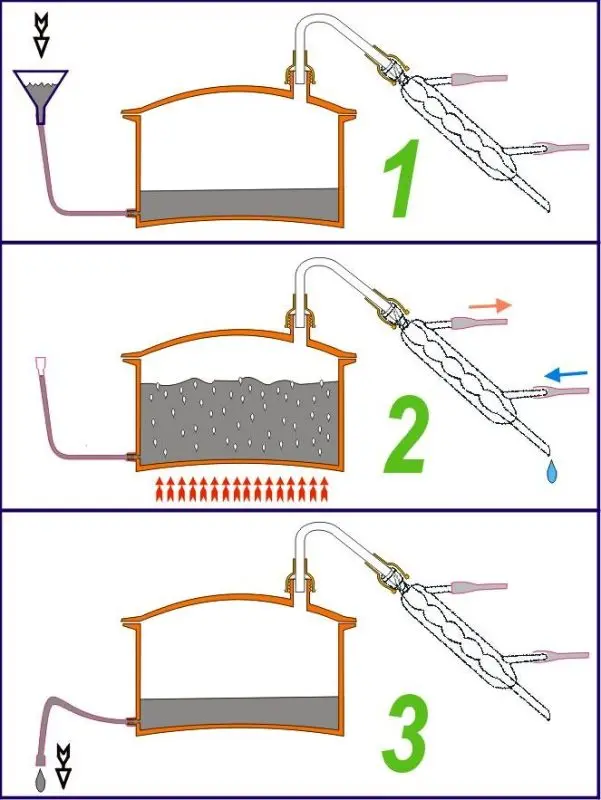

There is another fairly simple and functional system for preventing problems associated with overpressure. The idea is simple: a tube is put on the drain fitting, allowing you to fill in (1) or drain (3) the stillage. During the distillation process (2), this tube is placed 600-800 mm above the cube and discharged into the sink. The height of the tube bend above the stillage level determines the overpressure in mm of water. Art., after which the liquid will begin to overflow into the sink. Naturally, the drain valve must be open.

Simple, reliable and allows for many modifications.

These inexpensive and uncomplicated devices allow you to avoid serious risks when brewing moonshine. Do not neglect their use.

The author of the article is IgorGor.