To obtain sugar moonshine, baking dry or pressed yeast is often used. If the technology is followed, a distillate of normal quality comes out. But it is better to make mash on alcohol yeast, designed specifically for the preparation of alcoholic beverages. We will consider the nuances of their use in this article.

Advantages of alcohol mash:

- the fermentation period is reduced to an average of 4-7 days;

- there is no abundant release of foam;

- due to the rapid fermentation of mash on alcohol yeast, it accumulates less harmful impurities.

Ingredients for a 30 liter container:

- sugar – 6 kg;

- water – 23 liters;

- alcohol yeast – 100 grams dry (or 500 grams pressed).

The indicated proportions are suitable for most types of domestic and Belarusian alcohol yeast, but the ratio of water and sugar may differ for foreign manufacturers. Before you put the mash, carefully read the instructions for the purchased yeast and follow the recommendations. For example, some producers of “fast” yeast, due to the high intensity of fermentation, recommend not installing a water seal.

It is important to take into account the tolerance (survival) of the yeast strain to the concentration of alcohol in the wash. This indicator is indicated on the label and for most types of alcohol yeast does not exceed 16-18%. After reaching the maximum strength, the yeast will not process the residual sugar into alcohol (the mash that has won back will remain sweet). This does not affect the quality of moonshine, but the sugar will be wasted.

You can calculate the proportions of the mash, based on the maximum strength after fermentation, with the following calculator.

Counting in progress…

Enter the initial data on the left

The output will be mash with content and specific gravity

Would need

Braga recipe with alcohol yeast

1. Heat water (purified or bottled) to 30-32°C.

2. Mix warm water and sugar in a fermentation tank in the proportions indicated by the manufacturer or calculated. If the total volume of the wort (water + sugar) is determined using a calculator, then in order not to separately measure the water, you can first put sugar in the container, then add water, stirring constantly until the desired volume is reached. All sugar should dissolve, and not fall out at the bottom as a precipitate!

3. Breeding yeast: pour 1 liter of sugar syrup made at the previous stage into a separate container, add alcohol yeast, mix well. Keep in a dark place at room temperature for 30-60 minutes until foam appears on the surface.

Rehydration (soaking in water) and activation (initial addition to a small amount of wort) of some types of yeast may be performed using a different technology or not required at all. This point should be described in the instructions.

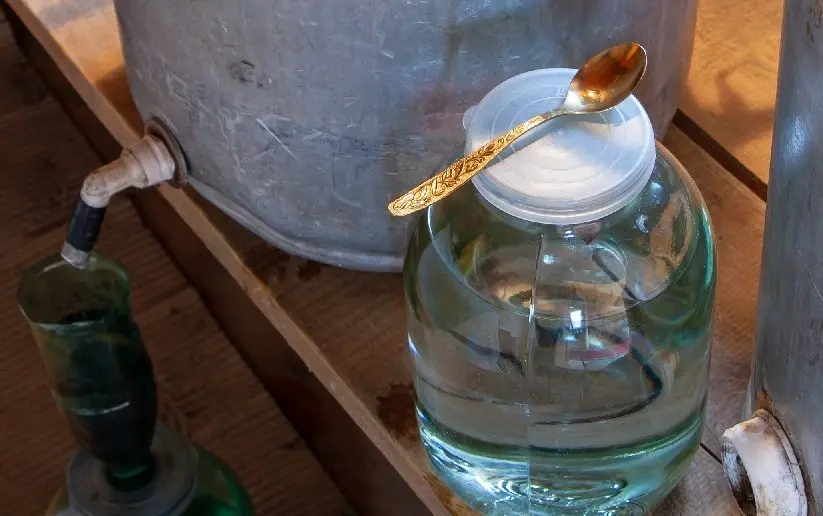

4. Add diluted yeast to the main wort, mix. Install a water seal.

5. Transfer the container to a dark room (cover) with a temperature of 25-30°C or indicated by the manufacturer as optimal. To maintain a stable temperature (it is highly desirable to avoid fluctuations, for example, day and night), heaters with automatic overheating protection can be used.

Fermentation itself raises the temperature by a few degrees, if the inside of the container is more than 33-35 ° C, the yeast may die.

6. Depending on the temperature and characteristics of the strain, the fermentation of the mash on alcohol yeast lasts 2-14 days (usually 4-7).

7. The washed mash does not emit carbon dioxide through the water seal, it becomes lighter, a layer of sediment appears at the bottom, the match brought to the surface continues to burn. The taste is bitter without sweetness (only if the proportions are calculated correctly).

8. Drain the alcohol wash from the sediment, additionally it can be clarified with bentonite or other methods. Overtake.