Contents

In general, the technology for making moonshine from buckwheat does not differ from the classical method for obtaining other grain distillates. But depending on the chosen buckwheat, you can make two completely different drinks in style: soft with fruity notes or harder with a hint of bread. If, after distillation, the distillate is kept in a barrel or insisted on oak pegs, an even more original version will come out – buckwheat whiskey.

Theory

Interestingly, buckwheat and buckwheat are the same concept. The plant itself is called “buckwheat”, and “buckwheat” is a derivative word for seeds. In everyday life, buckwheat is usually called green buckwheat (not roasted cereals), but in fact the name of the product does not depend on the condition.

Yeast can only process sugar into alcohol, and buckwheat contains starch, which must first be broken down to sugar, otherwise the mash will not ferment. The conversion of starch into simple sugars is called saccharification. There are several methods of saccharification, but the most affordable and natural is the use of unfermented malt – germinated grain (usually barley, wheat or rye), which contains the enzymes required to separate starch molecules. To activate the enzymes, you need: water, high temperature – 61-72 ° C and time (50-120 minutes).

For the preparation of moonshine, buckwheat of any condition is suitable: green or roasted grains (unground kernel), cereals, flour, prodel (chopped cereals). The taste and aroma of the drink is highly dependent on the degree of roasting of the grains. From brown (roasted) buckwheat, a moderately hard distillate with a bready tinge, reminiscent of barley moonshine, is obtained, and from green buckwheat, a softer drink with fruity and herbal notes. You can use any kind of malt, but to balance the taste, I advise you to use barley malt with brown buckwheat, and wheat malt with green (not roasted) malt.

Ingredients:

- buckwheat (whole, cereal, flour) – 5 kg;

- malt (white or green) – 1 kg;

- sugar – 1 kg (optional);

- water – 30 liters (and 4 liters for each kilogram of sugar);

- yeast – 150 grams pressed or 30 grams dry.

Proportions and output of moonshine

For normal saccharification and fermentation, 1 kg of buckwheat requires a minimum of 150 grams of malt. The amount of malt can be increased, but not reduced. In total, for 1 kg of grain raw materials (buckwheat and malt) you need 5 liters of water (and another 4 liters per 1 kg of sugar) and 5 grams of dry or 25 grams of pressed baker’s yeast.

With successful saccharification with 1 kg of buckwheat or flour, you can get up to 1 liter of moonshine with a strength of 40%. Also increases yield and malt. For example, from 1 kg of barley malt, up to 0,72 liters of forty-degree distillate is obtained, and from wheat – up to 0,92 liters (40%). But in practice, the yield of moonshine from buckwheat is usually 5-15% lower than theoretical values, since the grain rarely contains the maximum amount of starch, and part of the alcohol is lost during distillation. 1 kg of sugar increases the yield by 1,1-1,2 liters (40%), but neutralizes the grain aroma and taste, so I advise you to add beet sugar only if the rest of the raw materials are of poor quality.

Attention! It is very important to adhere to the temperature regimes indicated below, otherwise the starch will not break down into sugar. An error is allowed – up to 3 degrees. It is impossible to control the temperature of the wort without a thermometer.

Buckwheat mash recipe

1. If necessary, grind whole grains and malt to grits.

2. Slowly pour water over groats or flour at a temperature of 50-55 ° C (4 liters per 1 kg of raw materials). Stir constantly to prevent lumps from forming. The brewing vessel can be filled up to a maximum of 70%.

3. Put the pan on the stove, heat to 60°C, boil for 15 minutes, stirring occasionally.

4. Bring the mixture to a boil, cook for 60-90 minutes until a homogeneous porridge-like mass is obtained. In most cases, cereals need to be cooked longer than flour.

5. Cool the resulting porridge to 63-68°C. Slowly, stirring all the time, add malt. Make sure there are no lumps.

6. Bring the temperature of the wort to 63-68°C, cover with a lid. By periodic heating, maintain the specified temperature for 2 hours. Stir twice during the first hour, 30 minutes apart.

The porridge should become sweet, which means that the saccharification was successful.

7. Pour in the remaining water (preferably ice cold) and add sugar (optional). Cool down the wort to 25-28°C as soon as possible to prevent infection by pathogens. The easiest way to do this is by immersing the container in a bath of cold water or ice.

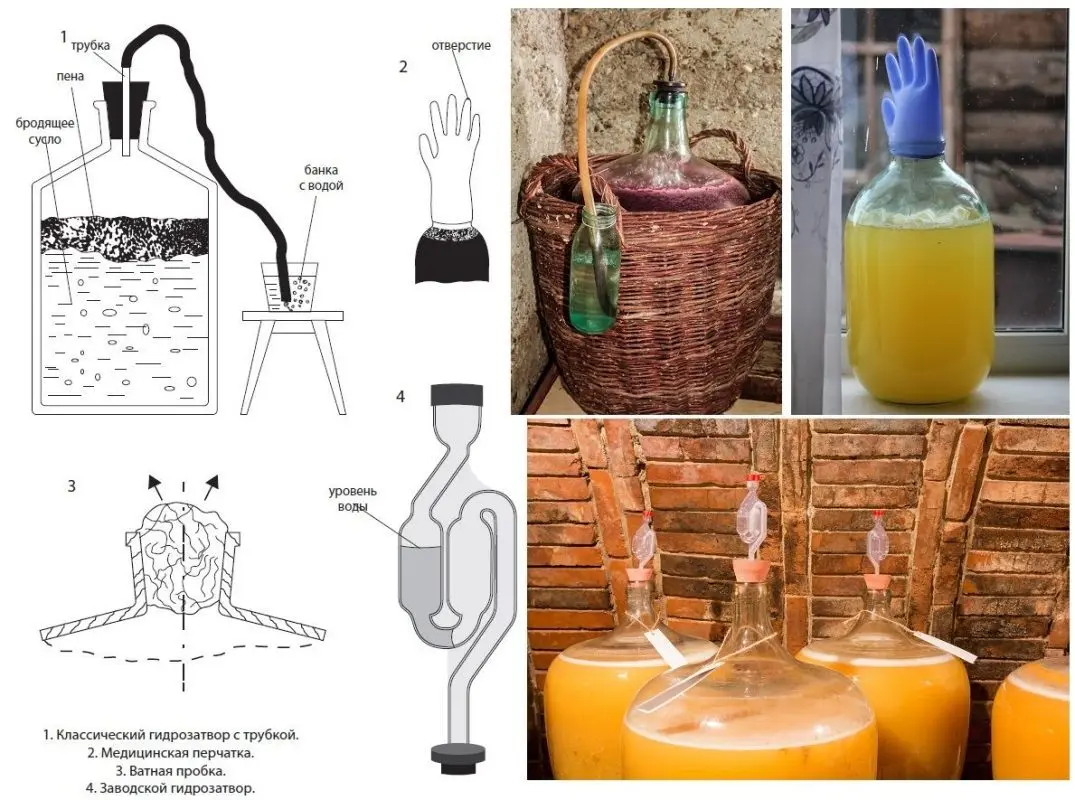

8. Pour the wort into a fermentation tank, add yeast pre-activated according to the instructions on the label. Install a water seal (or a glove with a hole in the finger), transfer the mash to a dark place with room temperature.

After 2-7 days, the buckwheat mash will win back: the water seal will stop emitting gas (the glove will deflate), the wort will lighten, it will become bitter in taste without sweetness, sediment will appear at the bottom. This means that you can start the distillation.

Obtaining moonshine from buckwheat

9. Drain the buckwheat mash from the sediment, otherwise the remains of the porridge will burn when heated, ruining the taste.

10. Drive the mash for the first time at maximum speed without separation into fractions. Finish the selection when the strength in the jet falls below 25-30%.

11. Determine the amount of pure alcohol in the resulting distillate – multiply the volume in liters by the strength in percent and divide by 100.

12. Dilute buckwheat moonshine with water up to 18-20%. Do a rerun. The first 10-12% of the yield from the amount of pure alcohol (calculated in the previous step) should be collected separately. This harmful fraction with a specific odor is called “head” and is only suitable for technical applications.

13. Withdraw the distillate (“body”) until the strength in the stream drops below 45%, then you can finish the distillation or collect the “tail” separately.

14. Dilute the main product with water to 40-45 degrees, pour into glass containers, seal tightly and leave for 2-3 days (preferably 7-10) in a dark, cool room to stabilize the taste. After that, you can proceed to the tasting.

Making homemade buckwheat whiskey

15. Whiskey differs from ordinary buckwheat moonshine only by aging in a barrel. The easiest way is to replace the barrel with oak pegs, wood chips (chips), which you can buy or make yourself.

The technology for preparing pegs and infusing distillate on oak wood is described in the article https://alcofan.com/dubovyj-samogon-nastojka-na-kore-i-shhepe.html (second option).

The use of store chips is described in the video.