Contents

Distillation is ambiguous. On the one hand, it is able to preserve the original taste and aroma of raw materials, on the other hand, a lot of substances of varying degrees of stink and harm to the health of drinkers get into the product. The easiest and most affordable way to clean moonshine from fusel oil and other “harmful” compounds has always been and remains activated carbon. This article should shed light on this area of home brewing and show really working ways to clean moonshine with charcoal at home.

Activated carbon is a general term for a group of various porous carbonaceous substances that have a branched internal pore structure that makes these substances absorbent. It can be produced from various materials of organic origin: charcoal (brands BAU, OU-A, DAK, etc.), coal, coconut shells, peat, etc. Activated carbon is the most popular and cheapest material used to purify alcohol.

Pay attention! Further, we will talk exclusively about the purification of raw alcohol, that is, distilled mash, and not the carbonization of the finished product. The last procedure no longer serves to purify the drink, which, after a careful and thoughtful second fractional distillation, is already quite pure, but to give it the taste of vodka due to the esterification reaction and saponification of esters. The drink accumulates substances that form vodka taste in sorting (but not the most useful aldehydes).

Cleaning should be subjected to moonshine, which ideally should be neutral. It is not recommended to clean fruit and grain distillates, the organoleptics of which are based on the taste and aroma of the feedstock, since coal absorbs not only harmful, but also flavoring compounds. It is definitely necessary to clean the moonshine from sugar or raw alcohol, in the mash for which it prevailed. Also, it would not be superfluous to clean, for example, rice or wheat moonshine on koji, which usually turns out to be quite neutral.

Types of activated carbon and methods of its production

Not all coal is suitable for cleaning moonshine, and some of its types can make the finished product even worse. The degree and quality of cleaning is influenced by the origin of the coal, the size and ratio of the number of internal pores, the size of the coal itself and, of course, the cleaning method. To begin with, let’s figure out which activated carbon suits us and what to look for when choosing it.

There are three main types of pores in activated carbons:

- macropores with a radius of curvature greater than 25 nm

- mesopores (transitional pores) with a radius of 1-25 nm

- micropores with radius up to 1 nm

Macropores are ineffective in cleaning and serve only as channels through which gas or liquid penetrate deep into the sorbent. Absorption of impurities occurs in mesopores and micropores. The pores are formed in the process of coal activation. This process can be carried out in two different ways, and both of them create a completely different pore structure:

- Chemical activation of coal

It is mainly used to activate charcoal and peat charcoal, as well as stone charcoal, for example, from olive pits. Activation occurs simultaneously with the production of coal. The raw material, usually wood chips, is mixed with an activating and dewatering agent, usually phosphoric acid or zinc chloride. Activation occurs at low temperatures, usually between 500 and 800оC. The agent causes the wood to swell and open its cellulose structure, and then acts as a stabilizer preventing the very porous and brittle absorbent from breaking down. The reagent is then washed out and reused.

The carbon activated in this way acquires a structure with a large number of open pores, which is ideal for the absorption of large molecules, for example, in the clarification of liquids. As a rule, such activated carbon is crushed to a powder form and used to treat liquids with a suspended absorbent (in our case, it is excellent for infusion carbonization).

- Activation of coal with steam

Steam activation has become more widespread and is used worldwide for the production of activated carbon from peat, coconut shell, lignite, anthracite, wood and coal. The raw material is first burned to the state of coal, and then, while its temperature is about 1000 оC, processed with steam at a temperature of about 130 оC. As a result, the impurities contained in the coal burn out and evaporate, leaving behind a porous structure. Its composition is highly dependent on the feedstock. For example, when burning and activating a solid material such as a coconut shell, it is mostly micropores that remain. Peat, on the contrary, is soft and gives a lot of mesopores.

Steam-activated carbon has the form of granules of various shapes and sizes, which is supplied to the market under the brands BAU, etc. Reformed activated carbon (compressed under high pressure after being treated with a binder) is also made, often in the form of pellets. Such carbon is used mainly for air purification and is not suitable for alcohol, because the granules are too large, their working surface is too small, and the contact time is too short.

Cleaning efficiency and pore size

Not the entire surface of activated carbon is an effective absorbent of impurities in moonshine. The largest area of its surface consists of micropores, usually 90-98%. About 1% is occupied by macropores. Many of the impurities in alcohol have molecules 2-10 nm in size – only mesopores can absorb them. Ideally, the pores of the carbon should be slightly larger than the impurities to be absorbed.

The pore structure is highly dependent on the raw material from which the absorbent was made. Peat activated carbon contains many meso- and micropores. During production, this balance can be controlled, for example, by increasing the content of mesopores for the multi-purpose use of such coal. Even pulverized peat coal contains mesopores.

Coal sorbents also have a developed system of micro- and mesopores. The most popular brands of activated coal have a grain size of 0,4-1,4 mm. Such coal is considered the best for filtering alcohol, but is expensive and not always readily available.

Lignin activated carbon contains many 1-4 nm mesopores as well as larger easily accessible mesopores. It usually comes in powder form.

Coconut shell charcoal mainly contains micropores smaller than 1 nm. They quickly become clogged with impurities and are ineffective in the future. Nevertheless, coconut charcoal is in demand and gives an acceptable degree of purification, since at the beginning of filtration its efficiency is 2-3 times higher than the rest of the activated carbon.

In wood activated carbon, and this is mainly birch charcoal of the BAU brand, which is popular in the CIS, there are most macropores and not many micro- and mesopores at all, therefore, in terms of absorbent abilities, it is significantly inferior to other coals. The situation can be improved by using a denser packing of the filter with smaller granules (up to 1 mm), which will give slower filtration and, as a result, longer alcohol-absorbent contact. Unfortunately, almost all BAU coals have larger particles (the grain size of the popular BAU-A is as much as 1-3,6 mm), except, perhaps, BAU-MF grade coal (GOST 6217-74), the grain size of which usually varies area 0,5-1,5 mm.

Ash content and subsequent processing of coal

The ash content of activated carbon is a measure of the minerals (Ca, Mg, Si, Fe, salts, etc.) remaining in it after production. We should be concerned only with water-soluble and alcohol-soluble substances that enter the filtered solution. If this is raw alcohol, then nothing terrible, because it will be subjected to distillation, but drinking sorting with this periodic table after carbonation is not very useful.

In production, activated carbon is cleaned with acid and then washed with water. But this does not give its proper purification from soluble impurities. Such carbon is always intended for filters to be properly prepared and run. The preparation process involves soaking the coal for 24 hours and then washing it for several hours. Only in this way and in no other way can you get rid of soluble substances in the absorbent.

Don’t believe? Try filtering water or alcohol through coconut charcoal without pre-preparing it. Almost always, after such cleaning, a whitish precipitate collects at the bottom of the tank. Coconut charcoal, as mentioned earlier, is composed mainly of micropores and is difficult to refine in production without spending a lot of resources on it.

Methods for cleaning moonshine with activated carbon

There are two fundamentally different ways to clean moonshine with activated carbon (we are talking about home-made drinks, not industrial, where there are many more such methods):

- Infusion method of carbing – activated carbon is placed in an alcohol solution, settled and filtered.

- Coal filter – an alcohol solution is passed by gravity through a cylindrical vessel filled with activated carbon.

The first method gives not a bad result, but in general it is ineffective and provides a weak degree of purification (this was repeatedly confirmed by laboratory tests). To really use the full potential of activated carbon, alcohol must be passed through a filter of a certain length, and the carbon itself must be of the required quality. But before such cleaning, it is useful to treat moonshine with powdered (for example, OU-A, DAK coal) or fine (grain size 0,2-0,4 mm) activated carbon, which will quickly clean raw alcohol or sorting from the main impurities. After this treatment, the filter is much more effective.

Pay attention! Raw alcohol before carbonation must be diluted to 15-20% alcohol, preferably up to 15%. At this strength, the dissolving properties of alcohol are reduced, which releases substances that can be absorbed. This has long been confirmed by laboratory tests and taken by moonshiners as a rule. For the same reason, carbonization of the product after its second distillation is ineffective in the context of purification, and serves only to give the drink a vodka taste.

Infusion method of moonshine charcoal

- Add 4 g of dusty or finely ground activated carbon for every 1 liter of moonshine. Mix well.

- Let stand for at least 24 hours in a dark, cool place.

Note: during this time, the mixture must be stirred at least four times.

- After the last mixing, wait for the coal to precipitate and filter the moonshine through a cotton filter.

- Carry out the carbonization procedure through the filter.

Cleaning moonshine with a charcoal filter

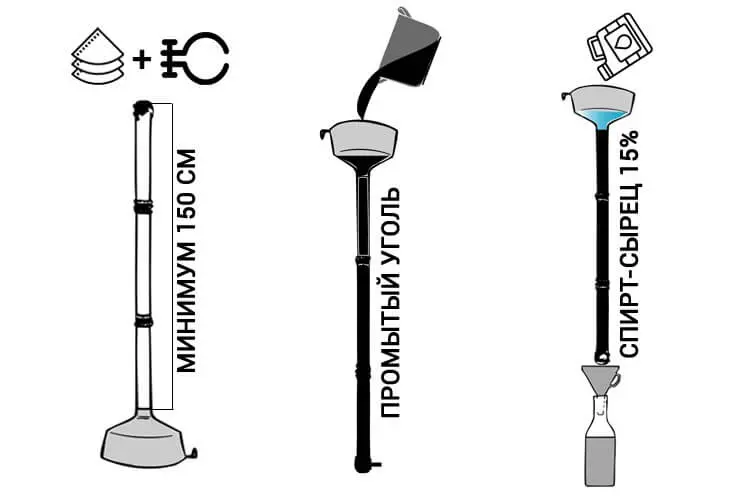

Filtration is carried out through a dense layer of activated carbon placed in a pipe 1,5-2,5 meters long. Inside the filter, the alcohol solution moves through the macropores in the granules, and cleaning is carried out due to the contact of the solution with the micropores and mesopores of the coal. To purify, for example, water, 5-10 cm of the filter layer is enough. For moonshine saturated with a large amount of impurities, usually 1,5 m38 or more is required. The pipe must have a diameter of at least XNUMX mm, otherwise a “wall effect” occurs, when alcohol, along the path of least resistance, will flow along the walls of the vessel without cleaning.

For effective cleaning, there must be no air in the pipe during filtration. This means that filtration should be carried out by a single flow of liquid (when filtration is stopped, aldehydes are actively accumulated in the pores of the coal, which, however, is not so critical for raw alcohol – just during distillation, you will need to carefully cut off the heads). The pipe and coal must be wet – this contributes to the passage of moonshine through the entire volume of the filter layer.

It is impossible to allow any channels in the filter layer through which the alcohol solution will move without purification, since it will hardly come into contact with the coal due to the air envelope (chemically bound oxygen blocks the pores). This will happen if you pour dry coal into the pipe and immediately start pouring alcohol. In other words, the carbon filter needs to be properly prepared.

When water or alcohol passes through the carbon, the first thing that happens is that the solutes left in the pores after production dissolve and pass into the filtered liquid. These are substances that did not evaporate during combustion and were not washed away after charcoal activation. Producers do not clean coal – it’s expensive. These substances (mainly salts) are also alkaline. When they dissolve, the pH in the tube rises from about 7 to almost 10, causing the cleaning efficiency to drop until the pH returns to normal (for water and alcohol, this is about pH 7). Therefore, activated charcoal must be rinsed before use.

The technology for effective purification of moonshine with a carbon filter with the correct preparation of the column looks something like this:

Pour the charcoal, stirring vigorously, into 2-3 times the amount of hot or simmering water in a stainless steel saucepan.

Pour the charcoal, stirring vigorously, into 2-3 times the amount of hot or simmering water in a stainless steel saucepan.- Stir with a large spoon and allow the coal to settle to the bottom of the pan, then drain off excess water. Repeat the procedure 4-5 times to clean the pores of the coal from soluble substances and saturate them with water.

- Coal can be immediately poured into the filter, but the cleaning efficiency increases by about 50% if it is first filled with hot water or boiling water and allowed to brew for 24 hours – during this time the coal will absorb even more water.

- Drain excess water. Pour hot or boiling water again, stir thoroughly, let stand and drain. Attach 2-3 paper filters to the filter tube and fill it with warm water.

- While the water flows through the filters, pour the washed coal into the tube. While filling the coal, tap on the tube to compact the filter layer. Filter at least 2-5 liters of water to wash out the remaining impurities and remove oxygen from the filter.

- Pour moonshine into the pipe when the last drops of water flow out of the filter (here it is useful to measure the water at the inlet and outlet of the pipe and change the receiving container in time or, preferably, use a glass tube to visualize the process) – so the coal does not have time to dry out, the air cushion will minimum.

- If you did not have time to fill in the SS or sorting in time, filter another 4-5 liters of warm water to remove oxygen from the pipe, but now do not yawn!

Filtration must be continuous, the filter layer must not dry out. It is best to attach a large funnel or container above the filter so that you do not have to add moonshine manually. The funnel must be covered with something so that the alcohol does not evaporate.

- Finally, when the last drops of alcohol flow out of the filter, filter another 1 liter of water to remove all alcohol from the tube.

This cleaning method is at least 100% more efficient than standard filtration through dry coal without preheating and washing it, as well as displacing the air cushion with water.

The resource of the column during the purification of raw alcohol with a strength of 15% is approximately 10 g / l. For example, let’s take a filter 160 cm long and 40 mm in diameter, its volume is about 2 liters. At the same time, 1 liter of the filter holds approximately 400 g of BAU-A coal. In total, we have a column in which about 750 g of coal is placed (taken at a minimum) – its resource is 75 liters of raw alcohol.

In practice, this number will be much less (we take into account the different degree of “contamination” of moonshine, the gradual wear of the absorbent with the displacement of the cleaning zone, the low efficiency of the same BAU-A, etc.), but even if this is half of our calculations, we have a fairly economical and efficient installation for intermediate cleaning of distillates. Economical especially considering that activated carbon can be reactivated and reused.

Optimal parameters of the carbon column

There are two things that can greatly affect the degree of purification of moonshine in our filter. First of all, this is the size of the grains – the larger they are, the faster moonshine will pass through the filter layer and, accordingly, contact with coal for less time. If the grain size is 1-3 mm or more, cleaning will not take place, since the contact of alcohol with coal will be too short, the impurities simply will not reach the meso- or micropores.

If the coal is too small, the tube will quickly become clogged with it, and again, filtration will not take place. For home use, activated carbon is considered optimal, the grain size of which is 0,4-1,4 mm, better if 0,4-0,85 mm, but we have what we have.

The second factor is filtration speed. We will measure it by the hourly volumetric velocity (HVOS) of the liquid, for the calculation of which we need to divide the amount of purified alcohol per hour by the volume of the filter layer (we fill the tube with water – we record its volume).

When purifying alcohol, the NER is usually 0,25 (very, very slow), while water is purified at 2-3 NERs. To achieve those same 0,25 FSP, you need to take, for example, a tube with a volume of 1,7 liters (a pipe with a diameter of 38 mm and a height of 150 cm) and fill it with coal with a grain size of 0,4-1,4 mm. Then the filtration rate will be about 400 ml / hour, which is equal to about 0,23 FSP – it suits us. If the filtration is faster, the degree of purification drops markedly.

There are three ways to speed up the process:

- Use a wider pipe

- Use a longer pipe

- Use charcoal with a smaller grain size

If you increase the width of the tube, the volume of alcohol per hour will increase, but the FER will remain the same.

Reactivation of activated carbon

If the impurities absorbed by it are removed from the waste activated carbon, it can be reused. You can restore up to 80% of its effectiveness, which in practice is up to 100%, because it is rare that the absorbent is completely depleted. In theory, reactivation can be performed any number of times. Soft coal, for example, from peat, will “degenerate” with each subsequent cleaning, its granules will simply decrease. Harder varieties, such as coconut or coal, keep much better and can be reactivated hundreds of times.

There are two ways to reactivate activated charcoal:

- Heat (heat treatment)

- Ferry (steam recycling)

In the industrial sector, the first method is often used. The charcoal is dried and preheated to char the impurities in the pores. Then it is reactivated at a temperature of 700-1000 оC. Impurities turn into gas and evaporate. The process is carried out in an oxygen-free environment so that there is no ignition. The pores are cleaned and the charcoal can be reused.

At home, you can try to do the following:

Warning! Waste activated carbon mainly contains fusel oils, which usually have a boiling point of 138 оC. Fusel oils consist mainly of higher alcohols (amyl, butyl, propyl, etc.), the vapors of which are flammable.

- Pour the coal into a sieve and rinse under running hot water. Please note that coal with a grain size of 0,4-0,85 mm will wake up through ordinary kitchen sieves – to wash it, purchase a sieve with a finer mesh or skip this step.

- Pour the washed coal with boiling water in a stainless steel pan and boil for 10-15 minutes to evaporate some of the higher alcohols (it immediately regenerates by 15-20%). Cook until there is a smell. Repeat if necessary.

- After boiling, pour the charcoal onto a baking sheet and let dry. Place the baking sheet in the electric oven.

Note: during the reactivation process, always keep the hood turned on and the window in the kitchen open – flammable vapors must be immediately removed from the room.

- Preheat oven to 140-150 оC and ignite the coal for 2-3 hours.

- Turn off the oven and let the charcoal cool down – it is now ready to be used again.

We are not yet aware of amateur moonshiners who would use steam to reactivate. If you have any experience that differs from the scheme described above, please tell us about it in the comments to this article or write to us by mail (admin@therumdiary.ru). It is generally accepted that reactivated carbon is further suitable only for the purification of raw alcohol and is completely unsuitable for “vodka carbonization”, since the pores no longer have the oxygen necessary for oxidation reactions.

Delicious moonshine and its conscious use to everyone!

Pour the charcoal, stirring vigorously, into 2-3 times the amount of hot or simmering water in a stainless steel saucepan.

Pour the charcoal, stirring vigorously, into 2-3 times the amount of hot or simmering water in a stainless steel saucepan.