The basis for the manufacture of mash can be various starch-and-sugar-containing products. The list of such products is truly endless and even strange. It includes not only various vegetables, fruits and berries (from sugar beets and potatoes to cherries and mountain ash), but also caramel (with and without filling) and even ice cream. However, the best option in this case is the most sugar-containing substance, that is, sugar as such.

Preparatory work

Preparation of mash for moonshine based on sugar, in addition to the above product, you need ingredients such as water and yeast (based on: for 5 kilograms of sugar, 20 liters of water and 100 grams of dry or a kilogram of ordinary yeast). You also need to get a fairly roomy container for fermentation. It can be glass, porcelain, enameled, aluminum, and also made of stainless steel. In no case should you put mash in galvanized dishes or in suspicious plastic products of Chinese origin.

First of all, you should take care of the quality of the water. Ideally, you should take spring water or bottled proven brands. It is in such water that the yeast will feel most comfortable. In principle, you can use filtered tap water, having previously settled it or boiled it. But at the same time, it should be borne in mind that in the first case, the yeast, nevertheless, may suffer from the salts and chemicals remaining in the water, and in the second case, they may not receive the required amount of oxygen.

Next, granulated sugar and yeast are purchased. Sugar is recommended to be taken packaged in relatively small plastic bags. As for yeast, along with the usual alcohol or bread varieties, professionals in the field of moonshine highly recommend dry French yeast Saf Levure. At the same time, in order to reduce the active foaming “activity” of the latter, it is worth adding a bag of other dry yeast called “Saf-moment” to three packages of “Saf Levure”. However, if they are not at hand, you can get by with ordinary heavily crushed cookies.

Braga making process

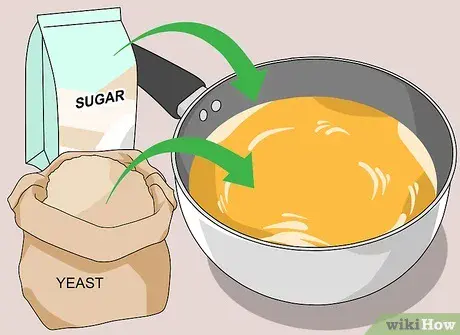

Making mash – first you need to prepare a kind of seed. That is, dilute the yeast with water at room temperature, in a large enamel basin or small tank. At the same time, the container should remain half empty for ease of mixing. If we are talking about ordinary yeast, then a little sugar should be added to them, at the rate of 100 grams per kilogram; if about dry, then do not forget about adding the aforementioned “antifoam” to them. In this state, the yeast should be about an hour.

As long as they reach the condition, it is worth preparing the sugar syrup, doing it directly in the fermentation tank. The container is filled with water heated to the optimum temperature for yeast: 25-30°C. Further, sugar is added in relatively small portions to the water. Each next portion is filled up only after the previous one is mixed and dissolved.

When the yeast in the basin swells, they must be mixed very carefully so that they are completely dissolved in water, after which the resulting substance is poured into sugar syrup. Further, if this does not diverge from the above proportions, you can add water almost to the brim; then close the fermentation tank with a tight-fitting lid equipped with a so-called water seal. The water seal must release the carbon dioxide formed during fermentation and, at the same time, prevent contact of the mash with air. The role of a water seal can be a specially made device mounted in the lid, equipped with an appropriate valve, or, in the case of a smaller volume of the container, a classic rubber glove with pierced fingers put on its neck.

Approximately, after 10-12 days, the maturation of the mash comes to an end. This can be recognized by the cessation of carbon dioxide emission (this is especially noticeable when using the aforementioned rubber glove, which at this point begins to deflate). If you use any other water seal, focus on stopping the noise coming from the tank during active fermentation.

A few practical tips

There are several folk tricks to speed up the maturation process of the mash. The simplest of them is the daily mixing of the substance, which contributes to the immersion of the so-called yeast cap to the bottom of the fermentation tank.

In addition, yeast can be “feeded” by adding an impromptu stimulant to the future mash. The role of such a stimulant can be: rye bread or tomato paste (100 grams per 10 liters), as well as corn or peas (2-3 cups for the same volume of liquid).

And, finally, to activate the vital activity of yeast, you can constantly maintain the temperature of the mash at the level of 25-28 ° C. This is done using a glass thermostat designed for aquariums and sold at any pet store.

Relevance: 06.09.2015

Tags: Vodka, mash, moonshine, Braga recipes