Contents

If you want to grow early vegetables or greens in your garden, you will have to take care of the temporary shelter of the plants from the coolness of the night. A simple solution to the problem is the construction of a greenhouse. There are many varieties of shelters, but a polycarbonate greenhouse with an opening top most often appeals to vegetable growers. Under such a mini-greenhouse, you do not need to allocate a lot of space, and the building will cost several times cheaper.

Why do opening sashes are made in a greenhouse

The greenhouse is designed for growing early greens, seedlings and low plants. A disposable shelter is usually made of a film or non-woven fabric, but the main structure is sheathed with polycarbonate. The sun’s rays pass through the transparent walls, warming the soil and plants. But back from the shelter, the heat comes out very slowly. It accumulates in the soil and heats the plants from evening until morning, when the sun hides behind the horizon.

Most often, a greenhouse or greenhouse made of polycarbonate is made from above opening. And why is this necessary, because the shelter is designed to keep warm? The fact is that the accumulated heat does not always benefit the plants. In extreme heat, the temperature inside the greenhouse rises to a critical point. Moisture is removed from the leaves and stems of plants. Due to dehydration, the culture acquires a yellow color, after which it disappears. To save the plants in hot weather, the sashes on the roof of the greenhouse or greenhouse open. Ventilation helps to normalize the optimal air temperature.

The second purpose of the opening doors is free access to plants.

Usually, in the manufacture of a polycarbonate greenhouse, the following dimensions are adhered to:

- construction length – 1,5-4 m;

- product width with one opening segment – 1-1,5 m, with two opening doors – 2-3 m;

- height – from 1 to 1,5 m.

Now imagine that there is a greenhouse 1 m high. Polycarbonate is not a film. It cannot simply be lifted up to water or feed the plants. All these plant care problems are solved when the top sash opens. A person gets convenient access to plants. The opening top allows you to make even wide polycarbonate greenhouses. To access the plants in such shelters, several flaps are placed on both sides.

Varieties of shelters made of polycarbonate with an opening top

According to the shape of the roof, greenhouses and greenhouses with opening tops are divided into the following types:

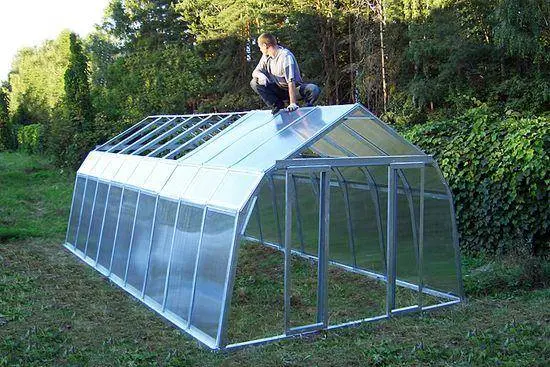

- For covering the greenhouse with arched roof polycarbonate is the best, one might say, the only material. Transparent sheets are elastic. They are easy to give the shape of a semicircular arch. The light weight of the sheet allows one person to work with polycarbonate. The high strength of the material withstands snow loads, but due to the semicircular shape, precipitation does not accumulate on the roof. The advantage of the arched structure is that condensate flows down the walls, and it does not fall on growing plantations. The minus of a semicircular roof is the impossibility of growing tall plants. This is due to the impossibility of installing ventilation windows on the long sides of the greenhouse.

- Greenhouse made of polycarbonate with a roof called “droplet”, is a subspecies of the arched structure. The frame has a streamlined shape. Each segment converges under a slope to the top, where a ridge is formed. The shape of the roof is very convenient in terms of low accumulation of precipitation.

- Double roof greenhouse resistant to heavy loads. The design allows the production of convenient rectangular opening doors. Gable polycarbonate roofs are installed even on stationary greenhouses. In such shelters, crops of any height can be grown. The only drawback is the high cost of construction. This is due to the complexity of manufacturing a gable roof.

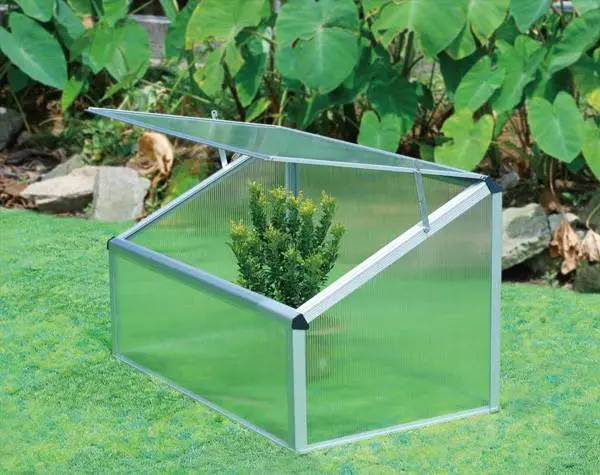

- Shed roof greenhouse resembles a box or chest, the lid of which opens up. The polycarbonate structure is made free-standing in the middle of the garden or adjacent to the house. Of the advantages of the shelter, only ease of manufacture can be distinguished. The sun’s rays penetrate poorly, the plants receive little light and develop poorly. With any slope, a pitched roof will collect a lot of precipitation, which increases the pressure on the polycarbonate. In winter, it is constantly necessary to clean off accumulations of snow from a shed roof, otherwise the polycarbonate will not withstand a lot of weight and will fail.

- dome shape greenhouse or greenhouse consists of triangular segments. Each element sheathed with polycarbonate creates a refraction of light rays, which ensures its dispersion inside the greenhouse. The sashes can be made so that the roof is completely, if necessary, open or partially ajar.

Shelter with any shape of the roof can be made independently and sheathed with polycarbonate. Opening sashes are made on hinges or they buy a factory-made mechanism. If desired, a ready-made polycarbonate greenhouse with an opening top can be bought at the store. Its frame is quickly assembled according to the attached scheme and sheathed with polycarbonate.

The most popular among vegetable growers are the following factory-made models:

- Name “bread house” greenhouse acquired due to its shape. The arched structure is made with one sliding sash upwards. Some models are sometimes equipped with two opening doors. The shape and principle of opening the sash is made like a bread box.

- Shelter model called “butterfly” the shape resembles a “bread box”. The same arched structure made of polycarbonate, only the sashes do not move, but open to the sides. When raised, the roof resembles the wings of a butterfly. The video shows instructions for installing a butterfly greenhouse:Video instructions for installing the Butterfly greenhouse

- A polycarbonate greenhouse in the shape of an opening chest is called “Belgian”. When closed, the structure is a rectangular structure with a pitched roof. If necessary, the sash is simply opened up.

Most often, the frame of factory greenhouses is made of aluminum elements. The finished structure is mobile and, if necessary, it can be disassembled for storage.

Advantages of polycarbonate greenhouses with opening doors

Buying or making a polycarbonate greenhouse yourself will cost a little more than just installing the arcs on the garden bed and stretching the film. However, this has its advantages:

- Compactness and mobility of a product allows to transfer it to any place. The materials used for the manufacture are lightweight, which will allow two people to rearrange the structure. Due to its small dimensions, the greenhouse will fit in the smallest suburban area where it is impossible to install a greenhouse.

- Polycarbonate and aluminum are inexpensive, strong and durable materials. As a result, the vegetable grower gets a cheap shelter that will last him for many years.

- A greenhouse with opening doors allows you to use the entire useful area of uXNUMXbuXNUMXbthe garden. Moreover, the vegetable grower gets easy access to the plants, which makes it easier to care for them.

If the arguments for the usefulness of a polycarbonate shelter are convincing, it is time to choose the optimal installation location.

Where is the best place to put a greenhouse

Small shelters made of polycarbonate are most often in demand in small suburban areas. In large yards, it is more profitable to install a greenhouse. Returning to small areas, it is worth noting that it is usually not necessary to choose the place for installing a greenhouse according to all the rules. The owner is content with the minimum free space.

When there is no desire to install a stationary greenhouse on a large suburban area, then they correctly approach the choice of a place for a greenhouse:

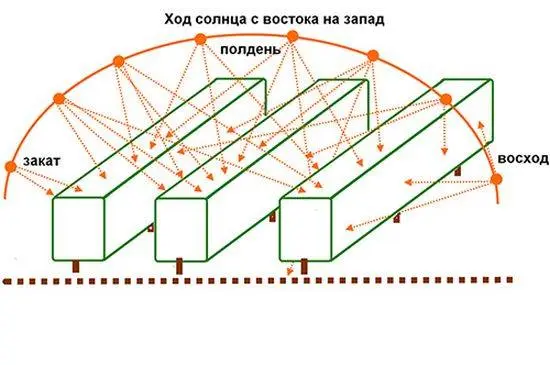

- The optimal location for installing a greenhouse is the southern or eastern side of the site. Here the plants will receive a lot of sunlight and heat. It is better not to install a polycarbonate shelter on the north or west side of the yard. The work will be in vain, and the vegetable grower will not see a good harvest.

- Maximum illumination is an important factor in choosing a location. It is undesirable to place a polycarbonate shelter under trees or near tall structures from which a shadow will fall.

- To keep warm in the greenhouse longer, it is placed in a place protected from cold winds. It is desirable that a fence or any other structure be as close as possible on the north side.

After choosing the optimal place on your site, it is prepared for the installation of a polycarbonate shelter.

Site Preparation

When preparing the site, it is immediately important to pay attention to the terrain. It’s best if it’s flat. Otherwise, the hills will have to be cleared and the pits filled up. If it is not possible to choose a site on a hill or the high location of groundwater interferes, it will be necessary to organize drainage. He will take away excess water from the garden.

The site is cleared of any vegetation, stones and various debris. Immediately you need to decide whether it will be a stationary installation or a temporary one. If the greenhouse will be permanently installed in one place, it is reasonable to build a small base under it.

Foundation manufacturing procedure

The polycarbonate shelter is very light and does not require a strong foundation. When performing a stationary installation of the structure, you can make a simple base of timber or red brick.

The simplest base is made using this technology:

- with the help of stakes and a construction cord, markings are applied on the site;

- to the depth and width of the bayonet shovel, they dig a trench according to the marking;

- a third of the depth of the trench is covered with sand;

- red brick is laid out with dressing, it is possible even without mortar;

- if the foundation is made of timber, the box is pre-treated with impregnation, roofing material is fixed from below and sides, and then installed in a trench;

- the gap between the brick or wooden foundation and the walls of the trench is covered with gravel.

The installed polycarbonate greenhouse, together with the foundation, is attached to pieces of reinforcement 70 cm long, driven into the ground. This will prevent the lightweight structure from tipping over in strong winds.

The assembly procedure for a polycarbonate store greenhouse depends on the model chosen. Instructions and a diagram are supplied with the product. Usually all elements are connected by hardware. Homemade frames are most often welded from a tube, corner or profile. Fragments of polycarbonate cut out from a large sheet are fixed to the frame with special hardware with a sealing gasket. The assembled greenhouse will only need to be fixed to the foundation and you can equip the beds.

For reference, this video shows the Umnitsa greenhouse with an opening top: