Contents

Polycarbonate garden gazebos are the best option for giving. Unlike heavy glass structures, they are 5 times lighter. Due to the optimal thickness of the building material – from 4 to 8 mm – even the simplest arched ceilings can withstand Epiphany frosts.

Types of arbors

The construction of summer arbors lasts from a week to several months. It all depends on the quadrature of the buildings, the features of their furniture and decor. In fully open verandas, polycarbonate is used to equip a waterproof roof. And since the material does not deteriorate under the influence of high temperatures, it is acceptable to use it in gazebos with barbecues. In this case, the owners do not need to think about where it is safer to use the device for cooking.

Closed structures provide better protection from rain, drafts and insects. To avoid the greenhouse effect, they are not recommended to be assembled from multilayer materials of a cellular structure. If there is no other option, you will have to use removable windows with Velcro from a polymer film. Depending on the type of raw materials, gazebos can be:

- brick with electrical wiring and autonomous heating;

- stone, located in the rear of a private house, away from the hustle and bustle of everyday life;

- plastic, not requiring a reliable foundation;

- welded with greater resistance to temperature extremes and other adverse external factors;

- wooden, where it is fresh, warm and cozy in any weather, and since the tree is a symbol of life and prosperity, this is an energetically favorable option for couples;

- living, entwined shady plants, where there are no protective surfaces, therefore, in choosing a place, it is better to prefer the back of the yard.

In shape, seasonal structures are square, rectangular, polyhedral and round. The latter are less subject to mechanical stress. Due to the good stability of the frame, shrinkage of the structure is possible only in 2% of cases.

If we talk about different roof options, most summer residents choose a shed type. This is a simple, inexpensive, and most importantly, safe solution for the most windy cities in Our Country, such as Severo-Kurilsk, Novorossiysk and Anadyr.

Video “Unusual gazebo made of polycarbonate”

From this video you will learn how to make an unusual polycarbonate gazebo with your own hands.

Advantages and disadvantages of material

Like wood, polycarbonate retains heat well, while allowing you to create an exemplary building shape. If we compare this material with glass, it is almost 7 times superior to the latter in terms of heat and sound insulation. Scattering the direct rays of the sun, polycarbonate maintains an optimal level of moisture and illumination in the premises. Other benefits for builders include:

- high resistance to heat and frost;

- good flexibility, due to which you can build a segmental or triangular arch with your hands;

- light weight, greatly facilitating work at height;

- impact resistance, allowing economical use of raw materials;

- color variability: from dark gray, on which dirt is almost invisible, to scarlet with less high thermal conductivity;

- excellent combination with metal, plastic and wood.

Transparent polycarbonate transmits up to 94% of natural light. The result is a visual expansion of space and almost 30 percent energy savings. From this material, lightweight country structures are obtained, which can really be installed directly on the ground. Another thing is two-story structures overlooking the lake, requiring a linear base. They provide reliable protection against seasonal bad weather in one case: if you choose molded polycarbonate at the stage of creating a project.

It is better to cover the roof with profiled sheets that look like a metal profile, and cellular polycarbonate is a profitable alternative to triple-glazed windows. Experts consider the only drawback of the material to be poor resistance to aggressive environments.

Wide sheets with a thickness of 2 mm can cover a gazebo with an area of 15 squares. Only with a weak fastening will they be blown away by the wind.

Simple building options

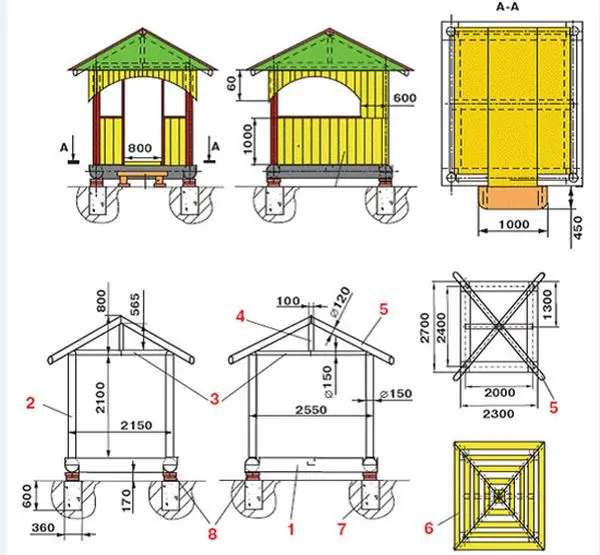

Not only durable, but also beautiful gazebos with a gable canopy are obtained from polycarbonate. The main advantage of such structures is a high-quality water conduit, due to which it is possible to double the shelf life of the structure. Before the main work, it is important:

- clear the site for construction;

- make a drawing of the future structure indicating the location and dimensions of the supporting elements;

- lay the foundation of;

- assemble a frame from a metal profile, which, unlike wooden elements, demonstrates greater resistance to moisture, temperature extremes and fire;

- sheathe the gazebo with monolithic sheets, and fix the blinds inside and decorate the window openings with plastic crafts.

Based on wood

Buildings made of glued laminated timber need high-quality exterior and interior decoration. For this purpose, professionals recommend cellular polycarbonate. In order to avoid technical errors, it is better to carry out the work step by step:

- Measure a wooden frame for an accurate calculation of building materials.

- Pick up sheets without defects.

- Mark cutting lines on products less than 6 m.

- Cut materials with a construction knife or disc plate.

- Remove sawdust with a vacuum cleaner.

To prevent moisture and insects from penetrating the products, their ends should be treated with sealed tapes. So it will be possible to increase the shelf life of the gazebo by at least 5 years. The next step is to attach the marked sheets to the frame. At the same time, the stabilizing layer, which performs protective functions, should face the street. After that, you can enter the screws at the corners of the frame or in their lower part.

It is important that the surface of the cellular material remains perfectly flat without damage. To do this, fasteners should not be screwed in at high speed. If dents still appear, go to reverse. At the end of the work, remove the protective film from the refractory sheets.

When choosing parts for point fixation of polycarbonate, it is better to prefer thermal insulating washers with an optimal diameter of 36 mm. Multi-colored polypropylene fasteners with poor UV resistance are more logical to use in shaded areas. Polycarbonate washers retain their original properties for a long time in any territory.

With metal frame

In the conditions of a metal frame, you will need a mount on the frame. To do this, you will have to make 2-centimeter grooves in it and use silicone sealant. If the owners prefer dry installation, you will need nuts, screws and self-tapping screws. In this case, seals do not need to be glued to the colored sheets.

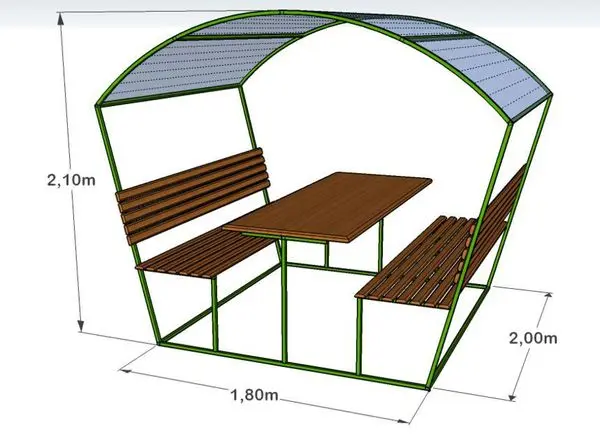

The acceptable distance between fasteners is 45–50 cm. If installation work is carried out in areas with significant height differences, at least 2,5 cm should be retreated from the edge. Small gazebos for children’s entertainment are sheathed with polycarbonate using double-sided tape. But polyamide glue provides a more reliable fixation of the sheets.

For the arrangement of small structures, one-piece profiles are needed. When performing roofing work, polycarbonate sheets are installed vertically. This is necessary for high-quality drainage.

Ready-made polycarbonate gazebos cost from 9 to 28 thousand rubles. In the first case, sheets with a minimum thickness are taken as the basis, and in the second – at least 6 mm. Such designs have a dozen details that can be assembled in 40 minutes, and if desired, decorate with organza air curtains.

For self-assembly, you will definitely need wrenches and power tools with adjustable screwing depth of fasteners.