Contents

In order to build a high-quality greenhouse on their backyard, most gardeners prefer to choose modern, solid translucent plastic. He became a worthy successor to the traditions of glass, which was previously used for arranging greenhouses. What type, color and width of the material should be chosen, and is it necessary to protect it from UV rays?

Polycarbonate type: monolithic or honeycomb

Polycarbonate for a greenhouse is the best solution for arranging a solid greenhouse for each owner. High-quality modern polycarbonate for a greenhouse must have the appropriate technical characteristics. It is lightweight – even the reinforced version of the material is light. In this case, the strength does not suffer at all. The level of thermal conductivity of polycarbonate for greenhouses is several times less than that of the usual glass. This is achieved thanks to the cellular structure, which allows you to maintain optimal temperature conditions inside the structure. Polycarbonate is better than glass, transmits light rays.

The scattering effect makes it possible not to think about shading the greenhouse. Sometimes the manufacturer supplies the material with a film that can protect it from excessive UV radiation. Modern material better tolerates mechanical stress and resists the vagaries of the weather. When destroyed, it does not form a scattering of fragments, it has a high degree of fire resistance. It has convenient overall dimensions. Installation of the greenhouse can be done even by beginners without professional equipment.

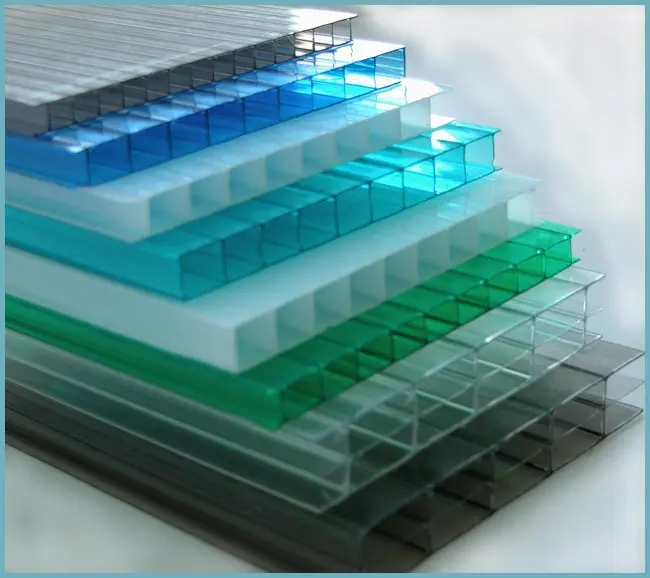

The classification of polycarbonate implies its division into cellular and monolithic types. Honeycomb is a transparent hollow material, the walls of which are inside. The sheet is similar to a sandwich, between the dense walls of which there are perpendicular stiffening partitions. Cellular polycarbonate weighs very little – 15 times less than glass. When replacing glass with this material, no additional fasteners are needed. Plastic is very flexible, which makes it possible to create a structure of complex shape.

What technical features are most important for covering a greenhouse

The honeycomb type of material has a light transmission capacity of up to 86%. The monolithic type does not have voids inside the sheet, like a honeycomb. It looks more like glass, only stronger. It weighs more than a cell phone and has a higher cost. Any type of material is also called profiled, since it is able to have a smooth or wavy surface. What type of material is best? Monolithic is more aesthetic in appearance, and the second is more practical and functional. The choice is always yours.

Decide on the width

An important parameter for the subsequent operation of polycarbonate experts call its width or thickness. Factory sheets of material are offered in a wide range – from 4 to 2 mm. The 5mm material is prone to deformation, but is popular with gardeners when arranging greenhouses. There are sheets that have an even greater width – up to 8 mm. They are used for the construction of outbuildings or covering canopies. Depending on the width of the sheets you will use to build a greenhouse, you will need to choose the allowable radius of its bend, the structure of the panels, the minimum distance between the supports, and the like.

It is important to make competent calculations of future snow and wind loads on the structure, air temperature in winter and summer periods. For standard medium-sized greenhouses – 3 by 6; 2, 8 by 8; 3, 2 by 10 meters, it is permissible to use sheets having a width of 4 to 8 mm. If the winter in the region does not have temperatures below 26 degrees, and in summer the thermometer does not rise to +34, then material of this width will be enough.

Video “UV Protection”

Choosing the optimal color

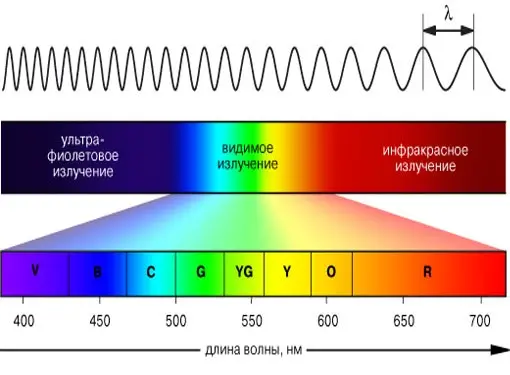

Dependence of UV radiation on the color of the material

Do not be surprised, because the question of which color of the material is better to choose is important. To decide which color to choose, it is worth considering that plants need a lot of light. This is true for spring and winter. Different manufacturers offer panels that are excellent in transparency – some are more “clean”, others are less. Turquoise and blue color is not suitable for the construction of a greenhouse – it changes the appearance of things, can be used as an advertising version of the material.

To decide which color to choose, you need to consider the rationality of using colored material. Transparent transmits the sun’s rays through the walls by almost 90%. Opaque, which gardeners use to protect plants from possible burns, provides light penetration into the greenhouse by 65%.

This can slow down the process of photosynthesis and adversely affect the normal development of plants. Plants receive less light if less sunlight enters the greenhouse through the structure. It is acceptable to choose a material of any color if it is important for the owners that the shades of green, blue and red absorb three times as much light. In areas with a favorable climate and the absence of strong winds, it is recommended to give preference to yellow.

The ability to transmit light in such materials is up to 72%. When breeding mushrooms and berries, it is better to choose polycarbonate of darker shades – green, brown, red. It is better to refuse to use blue or turquoise. It does not let in the light streams necessary for normal photosynthesis of plants. If you have access to inexpensive electricity to heat and light your polycarbonate greenhouse, you can build it in whatever shade you like.

UV protection – is it necessary?

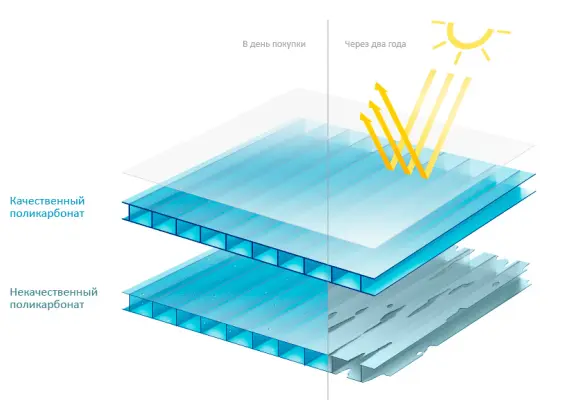

The consumer is advised to pay attention to the presence of UV protection of the material. Specialists and experienced gardeners are sure that such a parameter is needed for high-quality material. Surface application of ultraviolet coating is one-sided, double-sided, or the introduction of a protective layer into the structure. It is recommended to purchase materials with one- and two-sided coating for the construction of a greenhouse on a personal plot. If protection is included, then its percentage should be more than 46 and not less than 30%. This applies to all types of structures designed for outdoor use. Such characteristics need to be checked independently – they are indicated in the passport or certificate for the goods.

Video “Choosing a polycarbonate greenhouse”

In order to build the most adapted, reliable and fruitful greenhouse, the choice of polycarbonate should be approached as responsibly as possible. The video below will help you with this.