Contents

The final stage of the room separation is the installation of skirting boards. This is the final touch that completes the interior. Increasingly, instead of the usual wooden planks, a plastic floor plinth is used. It is low cost, easy to install and maintain.

Advantages and disadvantages

A plastic floor plinth is a practical solution that allows you to solve two problems at the same time – to give a finished look to the room and to hide, if necessary, wires, which are more than enough in our homes.

PVC skirting boards for the floor have the following advantages:

- Low weight

- Simple installation, no preliminary or subsequent preparation is required.

- Long service life, resistance to ultraviolet radiation, household chemicals.

- Easy maintenance, no need for regular renewal of the decorative coating.

- Harmlessness

Installing a plastic floor plinth is a practical solution. Gradually, they are replacing traditional wooden planks, as they are superior in many respects. There are few shortcomings. First, plastic is not a natural material. The second is the combustibility of plastics and the possibility of releasing harmful substances.

Nothing can be argued with unnaturalness, but there are already so many such “unnatural” things around that it still won’t play a role detail. In addition, good plastic is chemically neutral, in its normal state it does not emit any harmful substances.

The combustibility of plastics is different – there are plastics that do not burn and do not spread combustion, there are – with reduced smoke emission, in which harmful substances are still minimized. So if you want, you can find a non-flammable plastic floor plinth.

Types of plastic skirting boards

Plastic floor plinth can be of the following varieties:

- conventional;

- flexible;

- with cable channel;

- with a flexible (rubberized) edge;

- for painting.

Let’s take a closer look at each variety.

Flexible pvc skirting board

If it is necessary to arrange columns, curved walls, roundings, a problem arises – it is problematic to use ordinary rigid strips – you have to cut into small segments, join with connecting elements. It takes a lot of time, it turns out to be expensive for money, and the view is far from ideal, since it still turns out to be a broken line, and not a smooth curve.

In such cases, it is better to use a flexible plinth. The concept of “flexible” is relative. In its normal state, it is rigid, and bends well only when the temperature rises. Before installation on curved surfaces, it is heated with a building hair dryer to 60-70 ° C, bent into the shape that is required and fixed.

After cooling, it will acquire its original rigidity. They can easily arrange a column, for example, not to mention a smooth curve.

with soft edge

Plastic floor plinth is the most flexible of these products. If necessary, it can be pulled so that it will fit even against an uneven wall. But to achieve a full fit to an uneven wall without the slightest cracks is possible only if its upper edge is made elastic – rubber.

The elastic edge has the same color, although it is made of plastic material. Due to its high elasticity, it goes around even the slightest irregularities, leaving no cracks or gaps.

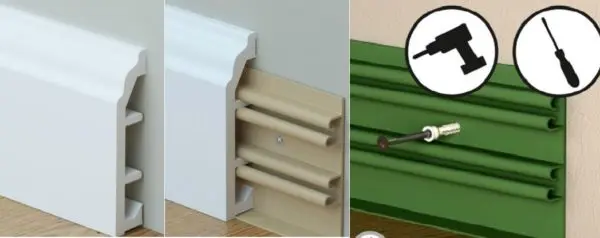

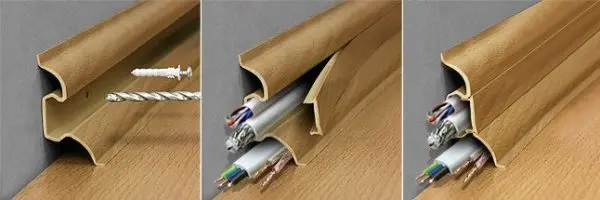

With cable channel

In a modern home, there is more and more equipment and wires going to it. One of the most convenient and cheap ways to covertly run cables around an apartment or house is to install a plastic floor plinth with a cable channel.

The cable channel is a specially formed recess/cavity along the entire length of the skirting board. Several wires are laid in this recess – television, telephone, computer cables. There are two types:

- With a molded recess in the body of the baseboard itself and a removable decorative strip. First, the plinth is mounted, then the cables are laid in the recess, after which the bar is closed.

This is a plastic floor plinth with a molded recess for cable routing. - Of two parts – a plastic / metal mounting plate, which is a cable channel and a decorative plastic lining. Cavities for cable laying are molded on the bar. It is mounted on the wall, a cable is laid into it, after which the plastic part – in fact, the plinth – snaps onto this bar.

This plinth with cable channels consists of two parts

The number of cables to be laid depends on the size of the cavities in them. More space is available in models of the second type – with a separately mounted cable channel. But the possibilities of the first type can be expanded by laying the wires in the cavities above and below the molded channel. The difficulty is that access to them will be difficult – they are also under the plinth. To get to them, you have to dismantle it. Therefore, it is desirable to lay wires here that rarely require maintenance – television, Internet, etc.

For painting

There is a plastic floor plinth made of foamed PVC. Due to the use of a porous material, the surface can be painted. A good option if you need a non-standard color solution. After all, the set of colors is still limited, and so you can choose the desired shade.

dimensions

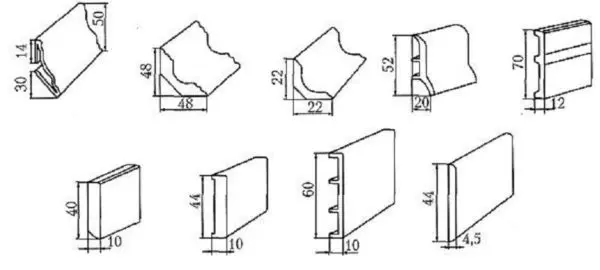

Plastic is one of the most plastic materials, allowing you to make products of any shape and size. Therefore, a plastic floor plinth can be of any section and size, but it still has certain limitations that are associated with the practical side. In general, plastic skirting boards are produced with the following parameters:

- height 50-120 mm;

- thickness 10-26 mm;

- length 2000-25000 mm.

Some types of plastic floor skirting boards with dimensions

These are the most common sizes, but there are single options. For example, there are wider ones at the bottom – about 50 mm. They are needed if the gap between the wall and the floor covering is somewhat larger than required by the technology.

Additional elements

When installing a plastic floor skirting board, you will need not only the skirting boards themselves, but also additional (additional) elements for them. This:

- External and internal corner.

- Connector – for splicing two pieces of plinth.

- Plugs – for cutting sections at the junction with the doors.

- Brackets – for laying cables in corners.

Types of additional elements for PVC floor plinths

The number of additional elements is considered for each individual case. You will have to count how many external and internal corners in the room being designed. It is also easy to count the plugs – two pieces are required for each doorway. A little more difficult with determining the number of connectors, but they can be taken with a margin.

Mounting methods

There are two ways to install plastic skirting boards:

- Screws or dowel-nails through the surface of the plinth.

- With the help of special clips.

There is also a way to mount

The second option is only suitable if the walls are perfectly even. On walls with curvature, it is better to use the usual method of fastening – with screws or dowels, a plastic floor plinth can be pulled close to the wall so that it will not lag behind the wall. In this case, it is better to use models with a rubberized edge.

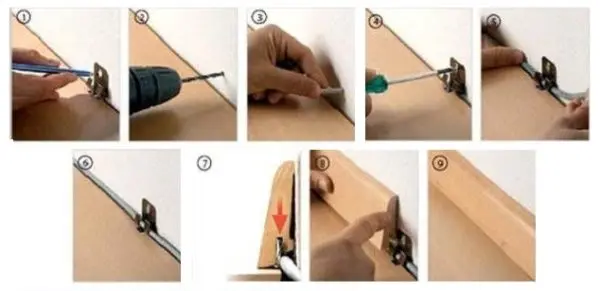

Fastening with a clip

This method of fastening is implemented using two types of clamps – clips in the form of separate plates and a long plate of the same length as the plastic plinth. The difference is that the long clamp is used as a cable channel, that is, in this case, cables / wires can be hidden in the plastic plinth.

The principle of fastening clamps of any type is the same:

- Clips attached to the wall.

- The plastic part just snaps onto them.

Fastening plastic skirting boards with clips

It is worth saying again: this method is only for perfectly flat walls, otherwise the result will be unsatisfactory. The order of work is simple:

- On the wall, at the height where the clip will be located, a mark is made.

- A horizontal line is beaten off at the mark (it is convenient to use a laser level).

- Focusing on the line, clips or a bar with a cable channel are attached.

- Lay cables. They can be additionally fastened with plastic ties or double-sided tape.

- The plinth front panel is installed.

PVC plinth with a separate cable channel is mounted almost the same

When installing, it is important to place the clips on the same level. Only in this case it will be possible to fix the decorative bar without problems. The allowable run-up is less than a millimeter, so we try to carefully check the position of the mounting plate or clip before fixing it. One option is to make a template. To do this, cut a piece about 15 cm long, make a hole in it and use it as a measure, applying it in the right places.

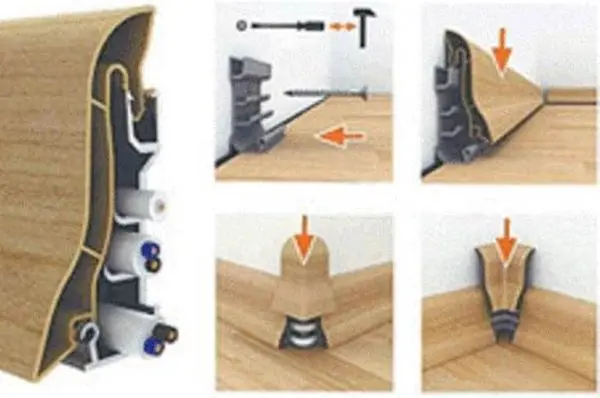

Mounting through the plinth, using dowels / self-tapping screws

This method is also suitable for not very smooth walls. A hole is made in the plinth, through it, with the help of a self-tapping screw or dowel, it is attracted to the wall.

Everything seems to be simple, but only until you start doing it yourself. And here problems arise: in what order is it better to drill, at what distance from each other to install fasteners, how to do it so as not to spoil the appearance too much.

There are several ways, but the most correct algorithm for installing a plastic floor plinth is as follows:

- We attach the bar to the wall, press it, align it. If there is an assistant, he keeps in a fixed state. If you’re working alone, secure it with masking tape. You can also drill and install one extreme fastener, which will firmly fix the bar and prevent it from moving.

Mounting through a plinth - We take a drill with a thin drill for metal 3-4 mm. Take a drill more authentic – so as not to spoil the plastic cartridge. We make marks on the profile and on the wall.

- First of all, we drill along the edges and in those places where the plinth “lags behind” the wall.

- We apply intermediate marks so that there is a distance of 35-40 cm between the fasteners (in extreme cases, more can be, but not more than 50 cm).

- We remove or move the plinth.

- According to the marks, we drill holes of the desired diameter. If dowels are used (with screws or nails), then we take the drill 1 mm larger than the diameter of the nail / screw. When using self-tapping screws, the drill diameter is 1-2 mm smaller than the screw diameter.

- We return the bar to its place, put on the required additional elements on the edges, install the fasteners.

- Attaching the next piece.

Drilling and not ruining the baseboard or flooring is the task

The last stage is the masking of the installation site of the fasteners. This step is omitted if the plastic floor plinth was with a cable channel formed and the fasteners were installed in this recess. If you had to drill through the front surface, mask the remaining holes with stickers in the form of small circles, which are selected according to the color of the plinth.

Choice of screws / self-tapping screws / dowel-nails

First, about the dimensions – the load on plastic skirting boards is usually not very large, so they take small fasteners. Optimal – diameter 4-5 mm (6 mm is possible), length – 25-40 mm.

Fastener color – white, yellow, black – choose depending on the color of the plastic plinth. The choice is simple – to be the least noticeable.

When choosing, look at the shape of the hat. It should be large and as flat as possible. In this case, masking everything will be easy.

A few practical points

When installing a plastic floor plinth with a cable channel, it is more convenient to lay cables already pulled together in some places in a bundle. If the cables are very tight, they tend to pop out. In this case, it is more convenient to use double-sided tape for the screed. It will hold the conductors in place.

Even with the correct calculation of the length of the plinth pieces (they should go 2-3 mm into the additional element), the outer corners tend to pop out. To get rid of this trouble, the connection is smeared with sealant. It is better to use silicone. After drying, it remains elastic, if necessary, can be dismantled.