Even such a powerful tool as a distillation column does not allow separating a separate impurity and withdrawing it from the column independently of the others. In practice, you need to group substances, but the boundaries between these groups are blurred. To solve the problem of removing the last drops of head impurities, a special unit of the distillation column – the pasteurization bar (CPU) helps.

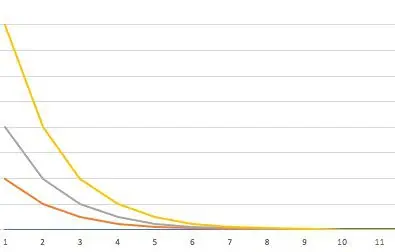

Theory. Selecting the head fraction, we let the column work for itself and accumulate head impurities at the top of the column, then we begin their selection for some time at a rate no greater than the rate of removal of these impurities from the cube into the column. The higher the concentration of these substances in the cube, the more of them per unit time enters the column. This determines that the concentration of impurities in the head fraction is maximum in the first hour of sampling, in the second hour it drops by about half, and in the third hour – by half.

If initially some substance contained approximately 2000 mg / l, then after 10 hours of selection of “heads” it will become approximately 2 mg / liter. If the impurity was 2 times less, then the desired 2 mg / l will be obtained after 9 hours, and if 2 times more, then after 11 hours. The time of selection of “heads” depends little on their initial concentration.

For high-quality removal of the head fraction, a lot of time is required. But even after the selection of the “head”, a lot of impurities remain in the column, smeared over the entire height. Therefore, we select the head restraints, washing the nozzle from their remnants.

After that, it seems that you can breathe calmly and begin to select the “body”. But if you strive to obtain really pure alcohol, you will have to pay attention to the fact that there are many different substances in the cube, which, during prolonged boiling, form new head impurities. In addition, in the reflux condenser at the border of alcohol vapors and air, oxidation occurs and new aldehydes are formed. Well, if patience was not enough for the 7-8 hour selection of the head fraction, then their remains will continue to flow into the column during the selection of the “body”.

All these factors add up and give a tangible negative result. To combat the last drops of head impurities, pasteurization bars are successfully used.

The concept of pasteurization tsargi

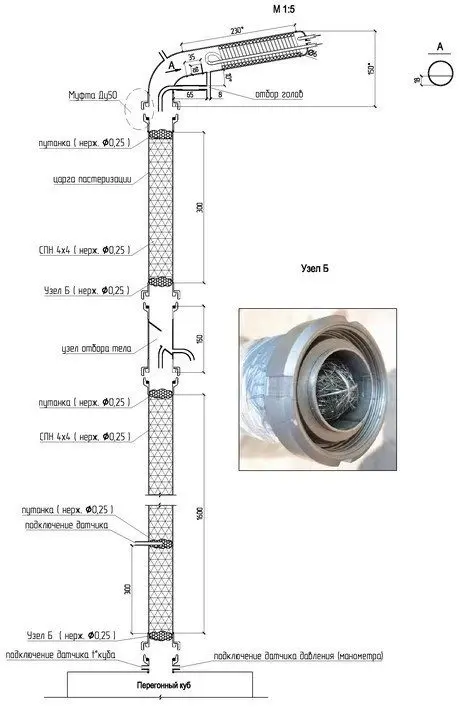

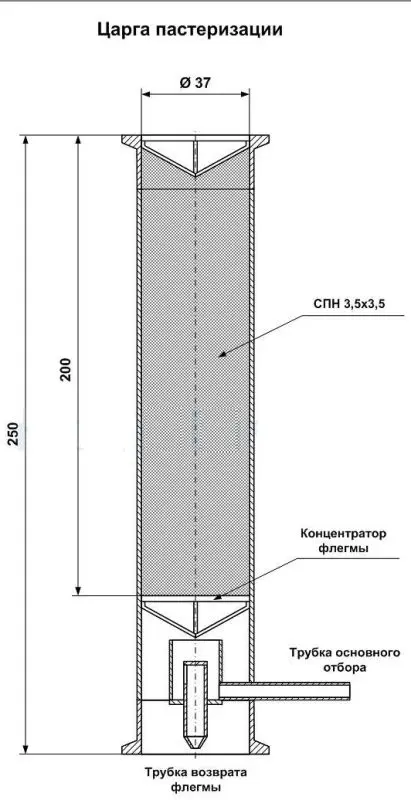

The pasteurization drawer is a drawer filled with a nozzle 20-30 cm high with a liquid selection unit at the bottom. It is installed between the column and the dephlegmator. When selecting “heads”, the maximum concentration of head and upper intermediate impurities is formed precisely in the CP.

“Heads” are cut off with the help of the dephlegmator selection unit, and at the end, the selection is not completely blocked, but continues, but at a speed 2-3 times less. In this case, the collection of the “body” is carried out from the selection unit located at the bottom of the drawer.

When choosing the height of the pasteurization drawer, do not forget about the need to provide 35-40 separation steps in the main drawer. Their lengths do not add up. To obtain alcohol, both with and without pasteurization, the main column must have a height of 1 to 1,5 meters. The CPU does not participate in the separation of the mixture in the column into fractions, it has its own specialized function – the release of the residual head fraction with volatile impurities flowing from the reflux condenser into the phlegm selection zone.

The “body” selection node divides the column into two parts, each with its own reflux ratio.

In the pasteurization cage, the reflux ratio is very high, because in the “heads” selection unit, the speed is only 15-20 ml/hour. At the same time, about 2 liters of alcohol per hour enters the reflux condenser on a 10” column. This means that the phlegm number will be about 500-600! In the main column, the reflux ratio is usually 4 for rectification at the start of the “body” selection and is regulated during operation according to the usual scheme.

Such a difference in reflux ratios leads to the fact that the pasteurization frame, like a pump, pumps out the head impurities from the main column and blocks the upper intermediate impurities, preventing them from descending to the level of the CPU selection unit.

Features of the operation of the CPU

The pasteurization drawer is very simple, but for successful operation it requires compliance with certain conditions. First of all, it is the stability, common for rectification, in the supply of heating power to the cube and cooling in the dephlegmator.

The second condition is the inadmissibility of hypothermia phlegm. It is clear that supercooled phlegm can easily displace the impurity concentration zone below the “body” selection unit and the pasteurization side will become nothing more than a fashionable decoration of the column.

The height of the CPU should be sufficient to accommodate a nozzle in it, providing a dozen separation steps (theoretical plates). For SPN, 20-30 cm is recommended. This is necessary to create a zone of impurity concentration. Insufficient height of the pasteurization side will lead to the displacement of impurities into the “body” selection zone.

When selecting alcohol, you do not need to strive for maximum strength. The zone of maximum concentration of upper intermediate impurities is only a couple of strengthening steps below the azeotrope point. Therefore, the approach of the alcohol withdrawal strength to the azeotrope shifts impurities to the concentration zone lower and lower down the column and increases the risk of getting the whole bunch of dangerous substances into the finished drink.

The purpose of using pasteurization tsargi is to obtain a cleaner, rather than stronger product, since alcohol will still need to be diluted to a drinking strength.

For the CPU to work correctly, the rectification process must be carried out without stopping. Start-stop technology is contraindicated here. If the selection is stopped, the alcohol buffer in the column will begin to grow, and that part of it that is located in the pasteurization cage and has an azeotrope strength will also increase. The impurity concentration zone will be forced out of the CPU into the main drawer. When the selection is resumed, the impurities will begin to move up and fall into the alcohol.

Too low a selection rate is another enemy of the use of pasteurization bars. If during conventional distillation, a decrease in the selection rate increases the reflux ratio and improves the quality of product purification, then in a column with a CPU, everything is not so. An excessively large reflux ratio contributes to the expansion of the zone occupied by the azeotrope and shifts the zone of accumulation of intermediate impurities down the column from the CP to the main drawer – to the selection zone. Working with a margin is inappropriate here.

When obtaining aromatic distillates, pasteurization can lead to unpleasant consequences. Ethers that have entered the CPU along with other volatile impurities will be removed through the upper selection unit.

Сonclusion

Pasteurization bars have long and firmly become part of the tools of rectifiers. Subject to simple principles, the CPUs give a tangible result in improving the quality of alcohol, but there is no way to control the process in real time.

If everything is simple with the head fractions – their withdrawal from the column is ensured simply by the presence of the CPU, then it is more difficult with the upper intermediate fractions. Depending on the technological modes, the zone of maximum concentration can migrate up and down the column or get into the selection zone.

Therefore, it is rational to buy a pasteurization drawer from a trusted manufacturer, and then use the CPU in accordance with the instructions worked out by the manufacturer during tests before serial production. Otherwise, you can get a toy that successfully simulates violent activity, but does not bring the expected benefits.

The author of the article is IgorGor.