Contents

Moonshine stills “Wein 4” represent a new stage in the evolution of column-type apparatuses from the production company “Wein” (Kirov). Compared to their predecessor “Wein 3” they have undergone a number of significant and not very changes. In this review, we will see how the device has become more perfect.

UPD. In May 2020, the line was developed in the form of the Wein Reform apparatus, and the Wein 4 was discontinued.

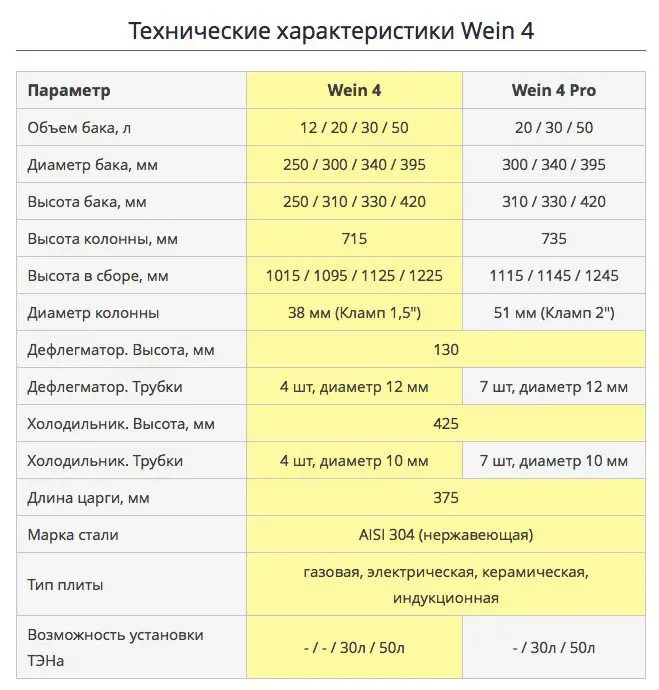

Technical characteristics of 1,5 “and 2” devices (“Wein 4” and “Wein 4 Pro”) are conveniently summarized by the manufacturer in one table.

Distillation cube

The basis of the cube has remained unchanged – it is the Chinese “Luxstahl” pan, repeatedly scolded and, nevertheless, recognized today as a non-alternative solution. Its main disadvantage is the manufacturing material – AISI 201 (12X15G9ND), this is a cheap replacement for AISI 304. The AISI 201 steel grade has sanitary and epidemiological conclusions about the possibility of using it in the food industry, but even manufacturers of railings and handrails use it only indoors. Outdoors, exposed to rain, AISI 201 rusts quickly. But this is not a sentence, most kitchen utensils are now made from it. You just need to know this feature and do not leave the pan wet after use, but wipe it dry.

The main reason for the scandal was not the use of AISI 201 for the manufacture of pans, but unscrupulous advertising claiming that they are made from more expensive and high-quality AISI 304. Many manufacturers have changed information about the steel grade on their websites to evasive: “food grade stainless steel”. But not the Wayne Company. Draw your own conclusions.

Cubes are still offered in 12, 20, 30 and 50 liter volumes.

The cover with a thickness of 1,5 mm became conical, which gave the necessary rigidity to the column fastening. This is a plus. The cover is made at the manufacturer’s facilities from AISI 304.

By inheritance, an anachronistic bleed valve from a pressure cooker passed into the lid. In combination with its fastening to the pan with an unregulated clamp, this leads to sad thoughts. At a pressure of 0,5 atmospheres, a sharp depressurization of the pan will result in a splash of hot bulk and a release of steam sufficient to create an explosive concentration of alcohol vapors in a small kitchen room. The slightest spark and an explosion will occur, taking out the interior partitions. The valve is designed for a response threshold several times greater than the dangerous pressure. And it doesn’t matter why the depressurization happened – the clamp broke off or the inexperienced distiller himself decided to see what was happening in the boiler. The consequences of this will not change.

The electronic thermometer, which came to replace the bimetallic monster, is, of course, a step, but not forward, but to the side. For some reason, the manufacturer decided that a thermometer with a short leg is cool. Yes, for the column – maybe. But for a thermometer in the lid of the cube – a real minus. Using this thermometer, we want to determine the temperature of a boiling alcohol-containing bulk. For what? To estimate its strength and in time to go to the tails.

The temperature of the vapor just detached from the surface of the alcohol-water mixture is equal to its boiling point. But the higher the steam rises to the column inlet, the more it cools. This happens both due to heat loss through the sides and the lid of the pan in the steam zone, and with the help of reflux flowing from the column. And if the thermometer is mounted in the cover not with a nipple, but is inserted into a welded-in sleeve, then this also introduces an additional error. At the entrance to the column, the steam, which at birth had a temperature of about 95 degrees, cools down by 10-12 degrees, approaching the condensation temperature of 83 degrees.

What will the thermometer in the lid of the cube show? some intermediate temperature.

The longer the tip of the thermometer, the closer its thermoelement to the boiling liquid, the more the readings will correspond to the temperature of the liquid. The shorter the tip, the closer the thermometer is to the inlet to the column, the more time the steam will have time to cool before contact with the thermoelement.

In a good way, the thermometer should be installed in the liquid zone, this is the temperature we need. And what to expect besides spoiled information from a couple acting as an intermediary?

Compared with its predecessor, the attachment of the valve for draining stillage has changed somewhat. Good or bad – the operation will show.

For cubes with a volume of 30 and 50 liters, it is possible to purchase them in a modification with an installed heating element and a control unit. They sell the device either with an installed heating element or without it, but in this case there will be no clamp. The control unit itself is the simplest, without voltage stabilization and indication of the current power. The unit allows you to smoothly adjust the power, focusing on the percentage scale.

There is also a highlight – a cube dehumidification sensor with a light bulb indication and automatic heating shutdown. The height of the sensor is approximately 8 cm, which means that the minimum minimum heap is about 11 liters.

For the production of moonshine, this block is a completely working option, but for the rectification mode, it requires serious improvement. The installation location of the control unit suggests that sooner or later it will be flooded with mash, what will happen after that is understandable.

In general, the distillation cube remained the same, progress has only touched on a more durable lid.

Characteristics of reflux condensers and refrigerators Wein 4

The 1,5” “Wein 4” column has an inside diameter of 35mm. This determines its operating power when using SPN 3,5×3,5×0,25 mm about 960 W, when using on-load tap-changers – about 1200 W.

The reflux condenser, having 4 heat exchange tubes with an internal diameter of 12 mm and a working length of 130 mm, allows you to utilize power up to 1800 watts. The steam speed will be 3 m/s. At operating powers of 960 W, the steam speed is 1,6 m / s, at 1200 W – 2 m / s. Excellent performance.

The refrigerator with 4 tubes with an inner diameter of 10 mm and a working length of 425 mm is able to utilize up to 3 kW of power supplied with a capacity of up to 6 l / h.

For a 2” “Wein 4 Pro” column with an internal diameter of 48 mm, the operating power when using the STC will be about 1800 W, with the tap changer – 2200 W.

A dephlegmator with 7 tubes with an internal diameter of 12 mm and a working length of 130 mm will ensure the utilization of up to 2,7 kW of power at a steam speed of about 2,6 m/s.

With an operating power of 1800 W, the steam speed will be 1,7 m / s, and for 2200 W – 2,1 m / s.

A refrigerator with 7 tubes with an inner diameter of 10 mm and a working length of 425 mm will quite cope with the power declared by the manufacturer of 5 kW with a capacity of up to 10 l / h.

Dephlegmators and refrigerators are well designed for the power and speed of steam in the steam tubes.

The only thing that causes alertness is the small length of the reflux condenser – 13 cm; when working with washcloths or a poorly wound tap changer, there is a risk of reaching modes in which the phlegm will supercool. Adding just a couple of centimeters of length would make these fears groundless.

Let’s be fair: the manufacturer has taken a huge step forward in improving the design of these important components.

Drawers of the basic configuration

In the basic configuration, 1,5” and 2” devices are equipped with 425 mm long drawers, not 375 mm, as indicated in the technical description. Well, what can I say? So that we are always so deceived by advertising …

The length of 425 mm allows you to install 4 taps and leave 2,5 cm empty space on top of the side for steam in addition to 3 cm of free space in the dephlegmator from the clamp to the tube sheet. A total of 5,5 cm is obtained, which is sufficient for the normal operation of the column.

A packing volume of 380 ml for a 1,5” column in the case of SPN is sufficient to retain tailings when distilling 8 liters of 40% crude alcohol into alcohol. You can successfully work with a 12 liter cube and in the mode of obtaining fortified moonshine – with a 20 liter one.

With the purchase of an additional drawer side, the total height will be 80 cm. This is enough to work with distillates and get a good degree of purification when working with a 30 liter cube.

The packing volume in the 2” column is 0,72 liters. When using SPN, this is enough to work with 14 liters of 40% bulk, that is, use 20 liter cubes.

To work with a 30 liter cube, you will need to purchase an additional drawer. With a 50 liter tank, to get a good cleaning at least 2 tsarg is also enough, but the transition to “tails” will have to be done at a cubic temperature of no higher than 92 degrees. The acquisition of additional tsarg with a total length of 80-110 cm will allow us to talk about alcohol.

Product spout

It’s embarrassing and funny. After a pleasant surprise from the design solutions associated with the new lid of the cube, dephlegmator and refrigerator, to see such a blunder in the design of the spout. A trifle, but in our business it is the little things that spoil the blood the most.

On the left in the picture is the design of the Wayne product selection spout, on the right is the correct design.

What is the fundamental difference? Of course, in the position of the drain tube. If the manufacturer recommends using the device in the “potstill” mode, then he is obliged to make sure that at small angles of inclination of the refrigerator, the product drains freely through the tube. The puddle accumulated in the glass should not block the steam pipes of the refrigerator. Therefore, the drain tube and TCA are made on diametrically opposite sides of the glass, and the glass itself is deep enough. What does enough mean? At the working angles of inclination of the refrigerator, the puddle should ideally not go beyond the glass, or at least not reach the steam pipe of the refrigerator that is in the lower position.

Everything is logical and simple. If the potstill mode is not recommended by the manufacturer as far-fetched and even harmful, then it is absolutely free from these design limitations. And such a nose can be considered beautiful. And there is no need to be afraid of this, many, having tried the “potstill” mode, never return to it again. The performance gain due to limited household heating capacities is more far-fetched than real, but the loss in raw alcohol quality due to spray entrainment is quite obvious.

Modes of operation

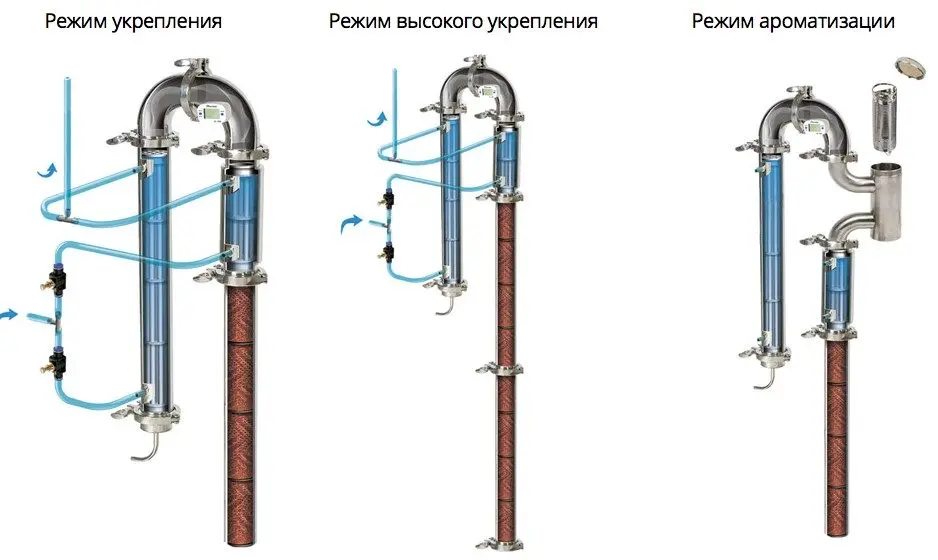

The manufacturer has declared the possibility of the device operation in several modes, the main of which are.

There are no exaggerations or advertisements in the description of these modes. On the contrary, surprisingly, there is a slight underestimation of the capabilities of this, I can already say with confidence, a beer column. You can add one more mode: by increasing the height of the column to at least one meter and using the SPN as a nozzle, it is really possible to get good alcohol. This is clear.

In the high fortification mode, you will get a drink that is close to alcohol in terms of the degree of purification. And if you replace the nozzle with SPN, then not every distiller will be able to determine without a chromatogram by flavoring that it is not alcohol.

Moonshine mode Vane 4

The mode of the moonshine still is a blunder of advertisers. Why do you need a nozzle without a dephlegmator? Probably, so that there was then something to wash off foam and splashes, and even reduce the productivity of distillation. This is just nonsense.

But here it is clearly seen that during the first distillation, due to the equality of the length of the refrigerator and the drawer, there will be problems with placing the apparatus on the cube. Apparently, the refrigerator will have to be tilted, reducing its efficiency, or an unconnected reflux condenser should be used as an extension of the drawer.

Additional options

Additional options included: nozzle selection, false bottom and aroma basket. Which is quite fair and made it possible to reduce the price of the basic version.

The false bottom is made on 5 six-centimeter legs, which is higher than the drain cock of the cube. The width of the slots is 1 mm, the length is 15 mm.

The design of the aroma basket is somewhat outdated, without a sediment drain tap. This does not allow you to make different bookmarks and get drinks with different tastes and aromas from one shoulder strap.

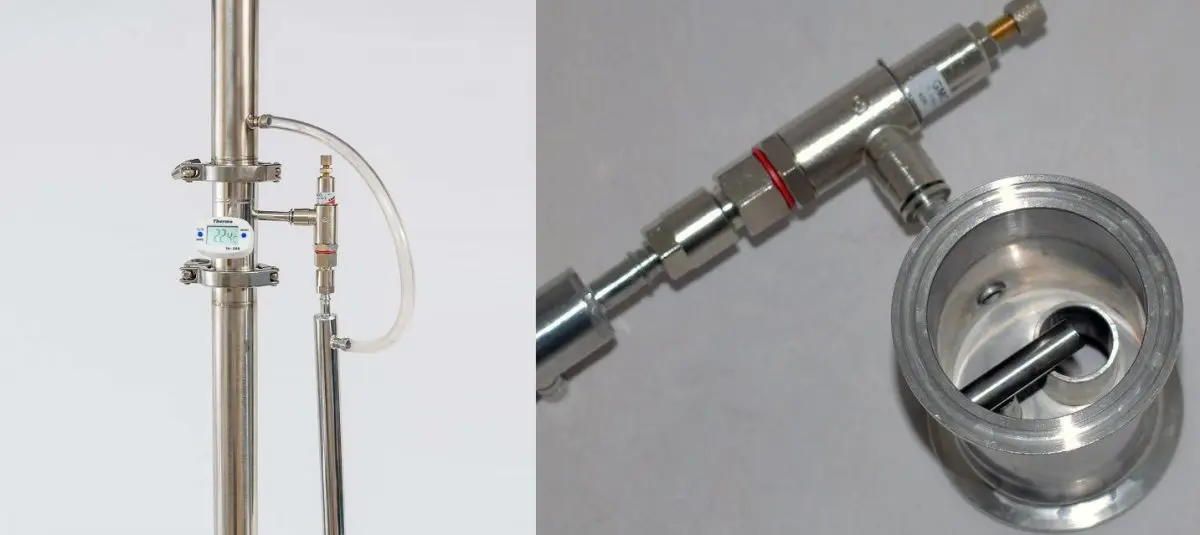

For distillers who have played enough of dancing with a tambourine during steam selection, Wayne offers a liquid selection unit. Its design is rather controversial and is a glass with holes for the sampling tube, located at a level just below the vertical phlegm return tube. For the passage of steam, there is a second vertical tube, with a larger diameter and a height that leads it above the level of phlegm in the glass.

Above all these tubes is a useless thermometer sleeve. Why useless? Because from below it is washed by steam, and from above by phlegm. The thermometer will show a certain average temperature, by the change of which, in general, nothing can be judged. Well, the temperature has risen by 0,2 degrees, and what does this mean? Either the steam became less strong and hotter, or the pressure of the water decreased slightly, and the phlegm became hotter. We are distillers, not fortune tellers. We need signals that are unambiguously interpreted. Otherwise, this offer is relevant and allows the company’s customers to move to the next level of comfortable work at minimal cost.

The proposed thermal jacket for the distillation cube is certainly a beautiful thing, but useless. The thickness of the thermal insulation must be at least 2 cm.

Wein 4 quality workmanship

An important question that usually takes buyers by surprise. On the pictures of the site, everything is exemplary, carefully processed, but in life, to put it mildly, it can be different. It happens, as in any production, marriage. It happens that the marriage goes on sale and the happy buyer enters into negotiations with the quality control department of the manufacturer. The whole question is how the problems that have arisen are solved.

There was a case when, after the first washing of the cube, literally before our eyes, rust appeared on the lid within 10-15 minutes. The lid was poorly polished initially, according to the buyer. Then everything is according to the scenario: communication with the hotline, after 5 days the answer is a decision to replace. New lid without flaws, perfectly polished.

Obviously, the manufacturer had a reason not to resolve the issue, citing possible chemical contamination of the surface. For example, the use of chlorine-containing household cleaners easily destroys the oxide film on the surface of stainless steel, and together with a kitchen washcloth made of ordinary steel, it gives a simply amazing effect. Issues were resolved in favor of the buyer.

In general, we can say that the quality has increased significantly since Wein 3. Welding is not jewelry, but quite solid. Compare for yourself: on the right “Wein 3”, on the left “Wein 4”.

The quality of the seam processing after welding is sometimes subject to complaints from buyers about traces of rust. True, in these cases, the replacement of parts was carried out without any questions.

conclusions

Moonshine stills of the column type “Wein 4” and “Wein 4 Pro” correspond to the declared characteristics.

When completed with additional tsargs, these devices can be safely called beer columns and with their help any products can be obtained, up to alcohol.

Disadvantages:

- the emergency pressure relief valve needs to be replaced with one that meets the technological requirements in terms of its response threshold;

- thermometer in the lid of the cube. It is better to transfer the sleeve to the liquid zone;

- spout for draining the product is not the best option for the “potstill” mode;

- the aroma basket is not equipped with a sediment drain valve;

- The thermal cover for the cube is decorative.

In general, the device can be recommended for purchase.

Reviewed by IgorGor.