Contents

Before us is the apparatus of the Wayne production company (Kirov). Of course, this is not the first constructor, as “modestly” stated in the description, and not the last. The package includes a cube and a collapsible column on clamp connections. Further in the review, we will deal with the characteristics of the Wayne 3 moonshine still. When evaluating, we will definitely take into account that the manufacturer guarantees high-quality work, both during distillation and in rectification mode. A very confident statement!

Distillation cube

The specified thickness of the walls of the cube is 1,5 mm, the bottom is 5 mm. In fact, the cube is made on the basis of the usual Chinese cauldron “Luxstahl”, the characteristics of which are easy to find on any site that sells dishes. The walls and lid of the pan, 1 mm thick, are made of AISI 304 steel, the three-layer bottom, 4 mm thick, is made of AISI 430.

Question to the manufacturer: why misinform?

The pot is suitable for an induction hob. Included with the device are cubes with volumes: 12, 20, 30 or 50 liters. All of them are equipped with a safety blast valve and a bimetal thermometer.

The disadvantage of this pan is well known – a thin cover 1 mm thick, during installation, the column of the apparatus will sway. For moonshine, this is not critical, but if you add a couple of tsargs in an attempt to assemble a distillation column, there will be difficulties even with ensuring a vertical position. The cooling water supply hoses will warp the column, dividing the reflux and steam paths.

The bimetallic thermometer TBP-63, placed in the lid, has an accuracy class of 2,5 with a scale of up to +160 °C. This means that the maximum allowable reduced temperature measurement error is ±4 °C. The division value is 2 degrees.

Rather than put a thermometer of such a low accuracy class, it is better to simply draw it on the lid, the effect on the result will be insignificant.

The manufacturer needed to transfer the thermometer to the liquid zone, since in order to successfully conduct the rectification process and cut off the “tails” in time, it is necessary to know the temperature of the distilled raw alcohol, and for this the thermocylinder must be completely immersed in the measured medium.

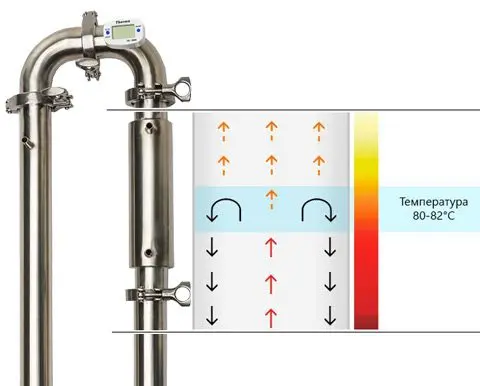

If the cube and the lid are insulated, and the system operates in the distillation mode, then the liquid and vapor temperatures in the column will be almost equal. There is no thermal insulation – a small, tolerable difference appears. But if you turn on the reflux condenser, everything changes – the temperature of the steam approaches the lower boiling point of the condensate returning to the cube.

With an increase in the reflux number, the temperature will drop, and the influence of drafts cooling the lid, reflux splashes and condensate dripping onto the thermometer from the lid will also affect. As a result, we obtain a certain equilibrium temperature, from the value of which we cannot learn anything useful.

Question to the manufacturer: maybe you should not mindlessly transfer design solutions for distillation to columns that operate using a different technology?

Column and kings

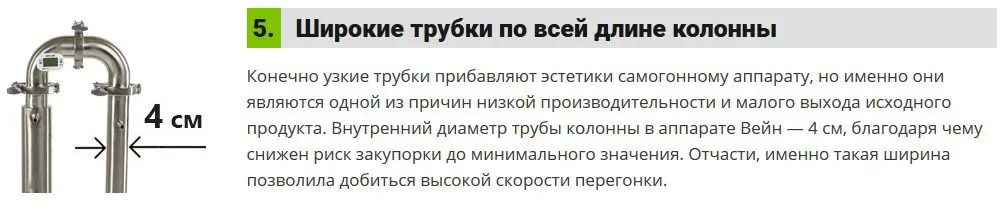

The company’s website says that the inner diameter of the column pipe in the Wayne 3 apparatus is 4 cm. In fact, this is not an inner diameter, but an outer one, and not 40 mm, but 38 mm.

The actual inner diameter of the column is 35 mm. The difference in performance between the declared and actual performance is about 30%. Again misinformation of a potential buyer.

The inner diameter of the column is 35 mm, the height of the drawer included in the basic set is 30 cm. This means that the volume of the nozzle is 290 cubic meters. cm. Even if used as a nozzle SPN, it can be guaranteed to keep the fuselage when distilling a maximum of 6 liters of raw alcohol. This is almost the worst indicator for mash columns as standard. Even with a cube of 12 liters, if you don’t want to have a fuselage in the selection, you will have to finish the selection of the “body” at 92-93 degrees. For ordinary moonshine, this is suitable, but for a well-purified distillate and alcohol – definitely not enough.

An additional 40 cm drawer side is included. This will add another 385 cu. see nozzles or 8 liters of processed raw alcohol. If this side was included in the main set, it would be possible to use a 12 liter cube without restrictions.

If you put another additional drawer side, then it will really turn out to use a 20 liter cube, and with two drawer sides – and a 30 liter cube without restrictions. As for the 50 liter cube, 22 liters of bulk is not enough, it can be used to obtain a purified distillate or alcohol with this column only by purchasing 3 additional drawers and a nozzle, and SPN is desirable.

Dephlegmator

With an external column diameter of 38 mm, the use of a jacketed reflux condenser is doubtful in itself. Based on the size of the dephlegmator, it will be able to utilize power from 800 to 1000 W, depending on the temperature and water flow. At the same time, at maximum performance, the reflux condenser will drive supercooled phlegm, which will begin to flow down the walls of the column, which will give almost zero wetting of the packing, which means that the effect of its use will be minimal. Therefore, jacketed reflux condensers are mainly installed in film columns with a diameter of up to 25-30 mm without a nozzle.

Everyone is struggling with the wall effect, centering the flow of phlegm and exposing the column strictly vertically, the manufacturer understands this very well – there are correct drawings on the site (see below). But at the same time he is trying to suggest that: “due to the temperature difference in the column, impurities flow down the walls, and pure alcohol vapor rises.”

In fact, part of the steam that touches the cold walls of the reflux condenser will completely condense, and the other part will fly through the center without hitting these walls, just like in the illustration. In order to obtain the effect of partial condensation, a minimum difference in temperature between the steam and the surface of the reflux condenser is necessary, as well as large areas in the manner of an alambic dome. So the fuselage will cheerfully fly into the selection.

Above the reflux condenser is a 90 degree turn with a thermometer.

Question to the manufacturer: how could one not weld 1,5 mm steel, and make a thermometer sleeve, resting it against the opposite wall? I wonder what this thermometer will show: the temperature of the steam or the wall of the column? Ten to one, which is the second.

Refrigerator

It is a long shell and tube with three tubes with a diameter of 10 mm. According to the reviews of the owners, such a refrigerator can cope with a heating power of up to 2,5-3 kW, but in the configuration the cube can be 50 liters, heated by 3,5 kW on an induction stove. A wise official dealer advises: “this is a designer – connect a dephlegmator in series in front of the refrigerator, and everything will be fine!”. Then why, having spent more than one thousand rubles, do buyers have to make something? Why did the manufacturer, having increased the cost by 100 rubles, not supplied tubes with a diameter of 15 mm and resolved the issue of matching the capacities of the equipment included in the standard package? Mystery…

The quality of the refrigerator manufacturing can be compared with the condition of the house of a bad housewife: the outside of the refrigerator is licked and polished, but inside the tubes are covered with burrs. Not the slightest attempt to clean the seams! This is not factory, but garage build quality, which is a shame to put up for sale.

After all this, it is no longer surprising that the product outlet nozzle does not have a tube for communication with the atmosphere.

The real possibilities of Wein 3

The rated power of a 35 mm column when using SPN is about 960 W, with OLTC – one and a half to two times more, depending on the density of the packing. This is the so-called pre-choke power, at which the column has the maximum possible separating power. To maintain a minimum reflux ratio of 4, which is necessary to obtain a well-purified product, when using SPN, the initial rate of selection of the “body” will be about 900-960 ml/hour. By the end of the selection, the rate will have to be reduced by 2-2,5 times to 400 ml/hour. This is necessary to clean the product well from impurities. And getting pure rectified alcohol will be problematic, if at all possible, due to the initially incorrect supply of phlegm to the nozzle.

For the on-load tap-changer, the situation is worse: in order to reach pre-choking power, 1,5-2 kW is needed, of which the reflux condenser can only utilize 800 watts. This means that the phlegm number will be no more than 2. If you try to carry out the drive at a lower power – about 1000-1250 W, then the phlegm number will become 4, but the power will be far from pre-choking. As a result, the separation capacity of the packing will be an order of magnitude smaller, and it is already depleted in reflux. In the best case, with additional drawers, you can get a strength of about 92% at a selection rate of about 800-850 ml / h, but there will be no separation into fractions and a decent level of impurity purification. You will get a very strong moonshine of below average quality, which will still need to be diluted to a drinking fortress.

For this design error, you will have to pay the “happy” owners of the miracle device.

To ensure good product cleaning with an on-load tap-changer attachment, a more powerful dephlegmator of a different design is required, capable of utilizing up to 2 kW. For the correct distribution of phlegm, it must be a shell-and-tube or dimrot.

If you drive fortified, but unrefined moonshine, then everything is fine, the speed is good. By supplying 2-2,5 kW for heating, we lose 200-300 W on an uninsulated cube and column, the reflux condenser utilizes even half of the remaining, as a result we get a phlegm number approximately equal to 1,5-2. We won’t remove the impurities, but we’ll pretty much halve them, if, of course, we put additional drawers in an amount corresponding to the bulk of the cube.

Modes of operation of the Wayne 3 apparatus

With 8 modes declared by manufacturers, in fact there are only 4 of them: “potstil”, column-type moonshine, strengthening modes with adjustable (fine tuning) and unregulated reflux condenser. There are two useful ones: moonshine mode and strengthening with an adjustable reflux condenser.

“Potsteel” loses to the mode of the moonshine still in terms of protection against splashing, and the method of distillation with an unregulated reflux condenser, if it is possible to regulate it, will only be used by an inveterate masochist.

The mode of the moonshine still is correct, and the productivity of 3-5 l / h is similar to the truth.

The strengthening mode with an adjustable reflux condenser (fine tuning) will make it possible to obtain the expected slightly refined moonshine with a strength of about 86%.

The rest of the modes are just an advertisement for additional equipment, although not always useless, for example, the use of an aroma basket will mask the fusel smell of moonshine, which will appear due to the insignificant holding capacity of the nozzle in the basic configuration column.

Conclusions and upgrade options

Wayne 3 is a good column-type moonshine with reinforcement. Suitable for home use, however, in order to become at least a good beer column, it clearly lacks competent design and workmanship.

For normal cleaning of the product, you must additionally purchase 2 drawers, and to get alcohol, you also need a third one, you also need a nozzle for the entire height of the drawer (for moonshine – RPN, for alcohol – SPN).

Along the way, it will be necessary to solve the problem of a low-power and inappropriate for the technology of heat and mass transfer of a jacketed dephlegmator, replacing it with at least a shell-and-tube. And when installing such a bulky structure, problems will arise with the thin lid of the distillation cube: it will be difficult to prevent rocking and set the column strictly vertically as required by the technology.

Reviewed by IgorGor.