Moonshine still “Sirius” from the company “Phoenix” – a novelty in the fall of 2017. The device is the flagship and the most popular model, which fans of this brand were looking forward to. In the current review, we will deal with the advantages and disadvantages, and also check whether the device meets the declared characteristics.

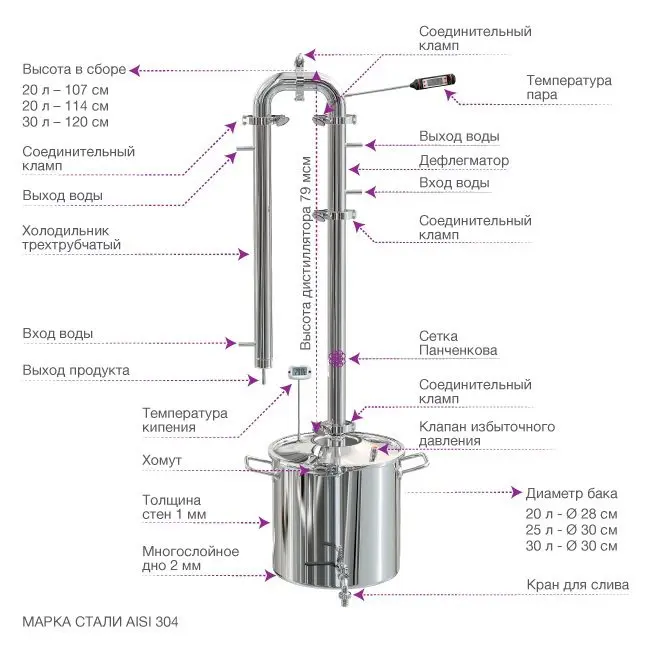

Description on the company’s official website: “The moonshine distiller Sirius is a unique solution built on the basis of a distillation cube in the form of a hermetically sealed pan with a clamp connector, as well as a full-fledged film-type distillation column with a built-in regular Panchenkov nozzle. This configuration allows the user to obtain high-quality, first-class moonshine of high strength and deep cleaning without re-distillation. The design takes up little space and the final product requires a minimum of time and energy.”

Cool? According to the description – this is a dream, not a device. Just before running to the store, let’s make sure that such loud statements are true and justified.

Cube

At first glance, the pan is very similar to its “sister” – LUXSTAL, but this is a completely different option. Wall thickness – 1 mm, covers – 1,5 mm, multi-layered bottom – 2 mm. The bottom is not only thin, but also has a non-flat shape in the form of two rings – a narrow outer, recessed middle, and an even more recessed inner circle, that is, the shape of the bottom is concave.

In the beginning, the bottom was not magnetic, and the pan was clearly not made for induction cookers. However, responding to the misunderstanding of potential buyers, the manufacturer quickly began to make the bottom of ferrimagnetic stainless steel, although the shape of the bottom remained the same.

Dealers selflessly prove that on their induction stoves during advertising brewing of moonshine, these cubes are heated even with such a bottom. This is true, but there is reason to think about the glass on the surface of the induction hob and the extremely small (along the outer ring) support area. The instructions for all induction cookers say: “the bottom must be flat to fit as closely as possible to the surface. Do not use pots and pans with a concave or damaged bottom. Written duplicated picture.

The lid of the pan is quite thin, so the beer column, especially with an additional side, will sway on it like a reed in the wind. For distillation, including fortification, this does not really matter, but if we talk about rectification or just cleaning moonshine using heat and mass transfer technology, this is a significant drawback.

The advantages of the cube configuration include the presence of a safety valve on the lid, a valve for draining the bard and the use of an electronic thermometer to measure the bottom temperature.

Finally, at least someone removed the bimetallic monster. If the digital thermometer were also properly fixed … Why such a small sleeve? The probe drops below the cover just a couple of centimeters. Okay, out of habit, we put a thermometer in the lid – although the place for it is below the waterline, in the liquid zone. But why not lower the sleeve to the full length of the thermometer probe, minimizing the influence of the temperature of the cover and the environment? In general, it is better to use not a sleeve, but a nipple. A penny detail, but the entire probe is in the steam zone and without intermediaries. However, all this is easy to upgrade and modify.

Cubes for the Phoenix Sirius apparatus are produced in volumes of 20, 25 and 30 liters. The geometric dimensions allow their use in the entire operating range of heating and bulking capacities without the risk of uncontrolled foaming of the mash. It is also possible to equip the cube with a 2 kW heating element with a simple power regulator.

In heat and mass transfer, for a good separation in the column into fractions and obtaining a pure product, the stability of the supplied heating power throughout the entire process is important. This is the alphabet. An ordinary dimmer, even in a beautiful box, will not provide power stabilization. We need other devices, for example, based on RM-2, which allow maintaining a given voltage with an accuracy of 1V.

The device that comes with Sirius can only be used for distillation, including with strengthening. In addition, it should be noted the extremely unfortunate place of its installation – it will not work to insulate the cube when working with a packed column.

Column

The Sirius column has an outer diameter of 38 mm, an inner diameter of 35 mm. Non-standard solution. The nominal capacity of such a column in distillation mode using SPN packing is 960 ml/hour, which is 20% lower than a conventional 40 mm column with an internal diameter of 38 mm. But a 38 mm pipe is cheaper than 40 mm, which is important in the pursuit of the budget, and the average buyer is unlikely to pay attention to such subtleties.

The height of the drawer included in the set of the device is 50 cm. It contains 1 wad of the on-load tap-changer nozzle 10 x 30 cm. So the remaining 4 wads need to be purchased additionally, if you want to get a purified distillate.

How purified? Nozzle volume 480 cu. cm. If you fill the SPN tsarga, then it will be able to confidently hold the fuselage with a bulk volume of 40% of moonshine up to 9,5 liters. This means that it is quite possible to work with a 20 liter cube, limiting the selection of the “body” to a cubic temperature of 92-93 degrees, and for large cubes it is better to add another 30-50 cm drawer. And the selection of “heads” will become clearer and more concentrated.

Dephlegmator

The photo shows the Sirius dephlegmator on the official website and two dealer websites. Even with poor picture quality, you can see that for some reason they do not look alike.

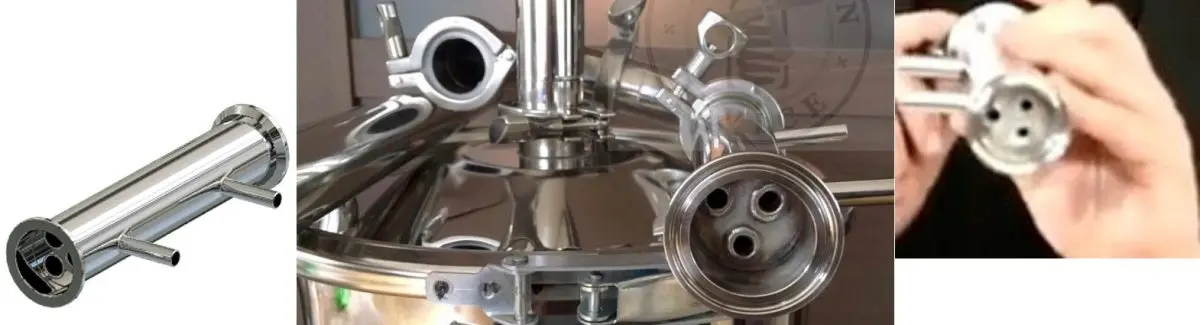

Since all the important technological dimensions on the manufacturer’s website are shrouded in mystery, we will use the courtesy of the official dealer, who published the characteristics of the device on his Youtube channel “Surrogates-no”. The actual dimensions of the reflux condenser and the entire apparatus were measured directly in front of the camera: length 19 cm, working length 14,5 cm, inside three tubes 8 mm in diameter each.

The power of such a dephlegmator is approximately equal to 1 kW. True, this is when it is connected according to the classical scheme towards a pair. When connected back, the efficiency drops by 15-20%, that is, it can be expected that the Phoenix Sirius dephlegmator will be able to utilize 800-850 watts. Not enough, but what if the nozzle is an on-load tap? Power should be much higher.

However, the main danger is the small diameter and number of tubes. During the operation of the dephlegmator, this creates the prerequisites for choking. The maximum steam speed will be at the bottom of the tubes – at the entrance to the dephlegmator, which can significantly slow down the reflux outlet, at the same time supercooling it. If, with an increase in the heating power, a certain critical level of steam velocity is passed, then choking will begin further. This power is not so great, only 800 watts.

The cross-sectional area of 1 pipe is 8 x 8 x 3,14 / 4 u50,24d 3 square meters. mm. There are 3 pipes, which means that the cross-sectional area for the passage of steam is 50,24 x 150,72 = 3 sq. mm. Useful heating power at which the critical steam velocity of 3 m/s will be reached: 150,24 x 750 / 0,6 = 800 kW. Or taking into account heat loss – about XNUMX watts.

This, in fact, was confirmed by the commercial of the “Surrogates-no” channel, showing the work of the column with the side, which is filled with on-load tap-changers. It was at this power that they managed to make the column work for themselves without phlegm and steam emissions into the refrigerator. If rectification is organized at the same capacity, then the “body” selection rate will be about 100-150 ml / hour, which will hardly differ from the “heads” selection rate.

Let’s face it: the capabilities of the reflux condenser put an end to the manufacturer’s advertising statement about the implementation of rectification on the Phoenix Sirius apparatus. And you can also forget about obtaining a distillate of a high degree of purification.

Increasing the heating power will not help, because the apparatus will immediately switch to the strengthening mode, in which the steam, entering the reflux condenser, will throw the phlegm condensed there into the selection, preventing it from draining into the nozzle in full and participating in heat and mass transfer processes. It’s not a rewrite anymore.

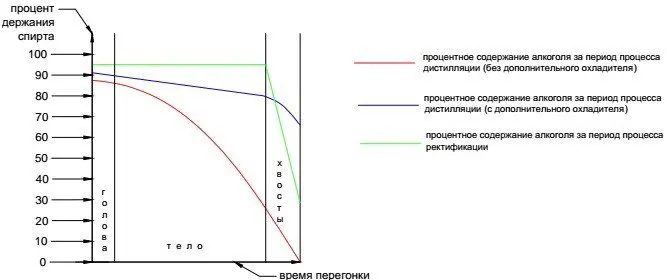

We received confirmation that the column in Sirius works in the fortification mode, and not fractional separation and sequential selection of fractions, in the next commercial of the same dealer. He quite honestly comments on the process of the second distillation on this apparatus with a drawer filled with a nozzle and a heating power of 1,8 kW, pointing out its peculiarity – a drop in the selection strength as the “body” is selected.

This is a classic case of fortified distillation. And not at all what you want to see from the use of a packed column. During rectification, the “body” strength is always the same, because an alcohol buffer is created in the column, which cuts off tail impurities at the same time from the selection zone. During distillation with strengthening, impurities enter the selection during the entire distillation.

In addition, the insufficient cross-section of the dephlegmator steam tubes with an increase in heating power creates a classic “swing”: the steam slows down the phlegm in the dephlegmator tubes, resulting in traffic jams. The pressure in the column rises and the plugs are pushed out by steam at high speed into the extraction. Then the pressure drops, and the phlegm continues to flow into the column, but slowed down by the steam again forms a plug, the cycle repeats. These vibrations destroy the fractionation in the column. It seems that some kind of strengthening is indicated in the selection, only its constantly changing speed, for example, its drip-jet character, hints at a problem.

With all the appearance of a successful heat and mass transfer process, we will find a complete list of tailing impurities of the feedstock in the product. Thanks to the technology of selection at low heating power offered by the manufacturer and its dealers, it will be possible to get rid of head impurities to some extent, but not from intermediate and tail impurities.

In general, there is a design error, confirmed experimentally by the manufacturer’s dealers.

In order for the shell-and-tube dephlegmator to work normally, it was possible to use the well-known simplified method for determining the cross-sectional area of steam tubes during the design. The total internal cross-section of the tubes in square centimeters must be at least five times the useful heating power in kilowatts. When heated at 960 watts: 0,96 x 5 = 4,8 cm². If you make 3 tubes, then the cross-sectional area of u4,8bu3beach is 1,6 / 14 u1,2d XNUMX cm², or a diameter of XNUMX mm. Then, with a margin of up to XNUMX kW, the dephlegmator will work without problems.

Refrigerator

The Phoenix Sirius refrigerator has a length of 53 cm, a working length of 49 cm. The design is the same as that of a reflux condenser. The power that the refrigerator is able to utilize is about 3,5 kW. This is quite enough for household needs.

The only problem with the cooler is the absence of an atmospheric tube in the lower part, so you need to make sure that the product outlet tube does not lie on the bottom of the can, otherwise, if the heating is accidentally turned off, the device will suck back into itself all the collected product that the tube reaches.

conclusions

Unfortunately, the manufacturer’s advertising promises turned out to be unjustified. Phoenix Sirius turned out to be a good moonshine still, but not a distillation column. The rest needs improvement.

Considering how much work was done during the preparation for the release of this model, let’s hope that the annoying errors described above will be corrected, and we will see a really good universal column.

Tips for those who bought “Phoenix Sirius”

Change the reflux condenser to a more suitable one, buy another 50 cm drawer and a nozzle. The lion’s share of the problems will be solved.

Further refine the apparatus according to the traditional scheme: insulate, hang thermometers, stabilize heating and cooling, make a parallel supply of water to the refrigerator and a new dephlegmator … There is a lot of work, but the road will be mastered by the walking one.

The review was made by IgorGor.