Contents

Bulat Bogatyr has been produced since October 2016 by the Helicon company at its facilities in Kirov. This is a large company known for a number of moonshine stills produced: Slavyanka, Finlandia Extra, Germany, Helikon, Gaus, Istochnik, etc. The devices are sold through the network of the manufacturer’s own official websites with the coordinates of the owner : IP Gainutdinov A.N. Sales of devices are also carried out through an actively created network of regional representatives, dealers and distributors. The company has equipment for laser cutting, plasma polishing, modern automatic and semi-automatic welding.

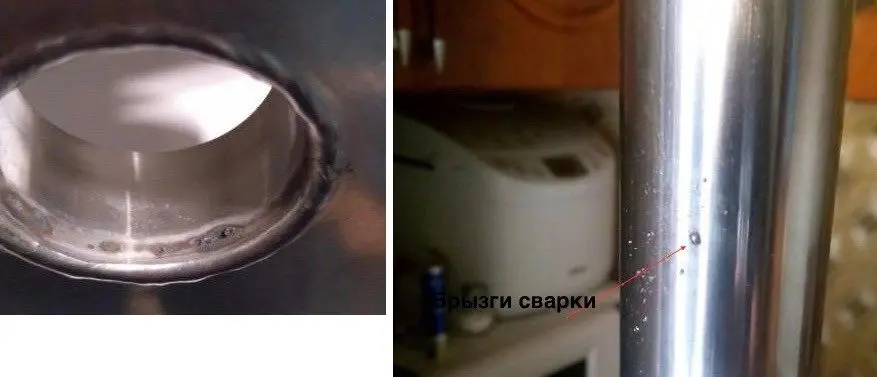

Moonshine stills “Bulat Bogatyr” are produced on a robotic production line with TIG welding with their own body with blowing the root of the seam. This is a matter of fair pride for the manufacturer. Such seams are considered the most effective today – the strength of the welded material is 20% higher compared to other types of welding.

A powerful advertising campaign and the presence of the manufacturer’s representatives at various forums of distillers raised the popularity of the device at the beginning of 2018 to a level that exceeded production capabilities. By the middle of 2018, the inscription “PHOENIX” modestly appeared on the cubes, and the number of complaints about the quality of equipment increased rapidly. The race for demand has driven the touted department of technical control into the far corner. And representatives began to appear less and less on forums to communicate with buyers.

However, it cannot be said that the manufacturer rested on its laurels. Work on the improvement of Bulat Bogatyr continued, and in the second half of 2018 the results appeared. The device did not stop in development. Modernization and improvement of the design goes on non-stop. It is hoped that quality control problems will be successfully overcome. Moreover, they are single, and not systemic in nature.

Let us consider in more detail what the Bulat Bogatyr is in the modification of the end of 2018, which is positioned as the second model.

Distillation cube

First customer disappointment. The website of the Gradus House trading network, which sells Helikon products, clearly states: “The wort kettle Bulat Bogatyr is made of stainless steel AISI 304, certified for food production, and has passed “field” strength tests.” The wall thickness is also indicated there – 1,5-2 mm (it varies on different pages of the site) and the bottom thickness is 5 mm, as the manufacturer – “Helikon”.

But upon receipt of the cube, the buyer is surprised to find another manufacturer’s brand name: “PHOENIX”. And this fundamentally changes things. The Phoenix brand is owned by Mosposuda and their Italian partner. And it is made, as usual, in China.

The thickness of the walls of the cube is not more than 1 mm. Handles are mounted on rivets and are additionally fixed by spot welding. The cube is made of stainless steel AISI 201. Just like the well-known “LUXSTAHL”. Apparently, this is precisely the reason for the problems associated with equipping the cube with an additional clamp connection for installing a heating element. Welding brand AISI 201 has its own characteristics.

Cubes are standard equipped with a vinasse drain valve and a 3 mm thick lid with two clamps and a thermometer. At the same time, the thermometer set an anti-record for quality. Not only is it a bimetallic thermometer with an accuracy class of 2,5 (that is, plus or minus 3 degrees), which is built into the steam zone and shows a certain average temperature of the steam and the lid, but according to the owners, the dial freely rotates around its axis at an angle within 10 degrees. However, to understand whether it is warm or hot mash, the thermometer allows, but is not capable of more.

The lid is attached to the cube using five collapsible clamping screw fasteners on 4 mm thick frames, replacing the standard adjustable clamp. The manufacturer, from his own experience, decided that it would be more reliable. And it is true. At least now the lid won’t come off before the safety valve from the pressure cooker works.

That’s just the safety valve disappeared from the package. So you have to take care of your own safety. For the designers of the apparatus, apparently, this is not important. Another problem is that the height of the clamp skirt is too low for attaching the column. Tightening the clamp screw is inconvenient, it was necessary to increase it at least a couple of centimeters.

The filler neck is the most controversial improvement of the apparatus. As if the spent stillage needs to be drained, and the cube washed before reuse. Otherwise, it will stick on the walls so that you can’t tear it off with your teeth. But in the case of placing the device under the hood, it can help out a lot. You will need an adapter though.

From the good things about the cube, we can say that the zigovka for installing the sieve still remains. And for a very understandable price, it can be purchased to work with thick mash and beer. The workmanship of the sieve is impeccable.

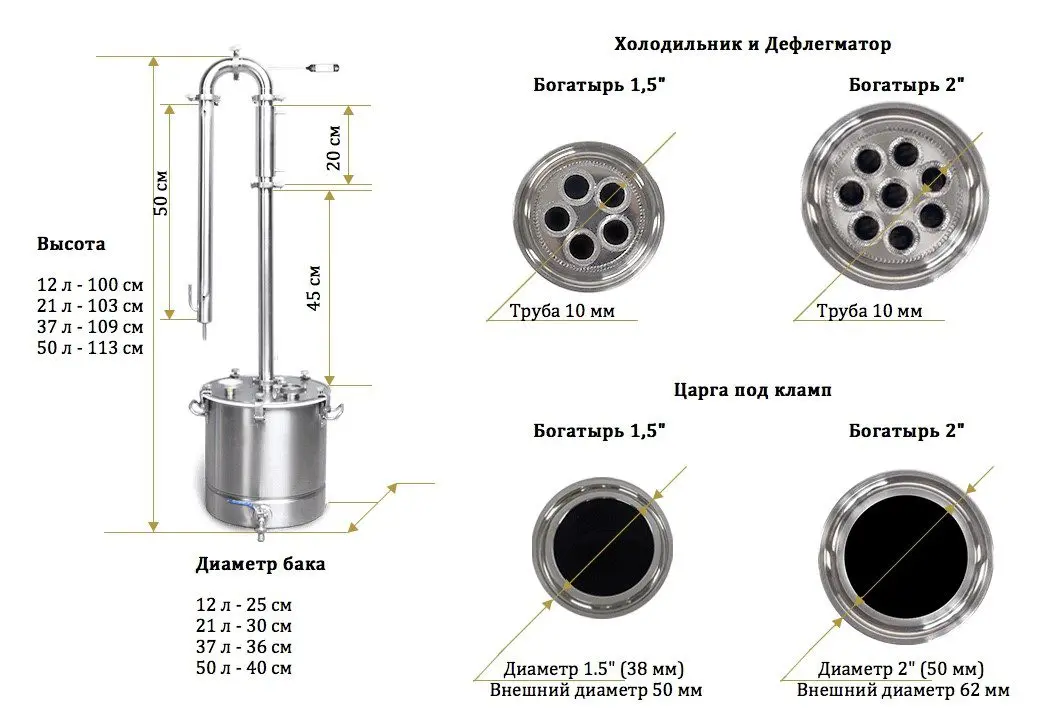

Cubes are produced in 4 sizes: 12, 21, 37 and 50 liters. In fact, their volumes are somewhat smaller due to zigovka. The diameters of the cubes increase with increasing volume and are quite consistent with the required power for the distillation of mash without the danger of uncontrolled foaming.

Column “Damask Bogatyr”

The sizes are taken from the official site and contain many inaccuracies in favor of the best sales. Who would doubt that…

The drawer side really has a length of 45 cm, which is due to the equipment of the apparatus with an on-load tap with a wad width of 10 cm.

With diameters, marketers were cunning. The diameter that determines the power and performance of the column is not the diameter of the clamp, not the outer diameter of the column, but the inner one. Which is equal to 35 mm for 1,5” and 48 mm for 2” columns. Accordingly, the rated power will be 950 and 1800 W when using the 3,5 mm SPN nozzle, and for the on-load tap-changer – about 20% higher.

Dephlegmator Bogatyr 1,5” has 5 tubes with an inner diameter of 8 mm. Not 10 mm as indicated in the picture, there are actually 8 of them. Accordingly, the 2-inch version has 9 tubes of 8 mm. It is very important. This is not about the utilized power, it is just more than enough, but about the steam speed.

If the user needs to ensure the pre-choke operation of the column in order to obtain the maximum separating capacity of the packing, then surprises await him. Dephlegmators at the limit of their capabilities will be able to provide stable operation only for the SPN nozzle. If you use an on-load tap-changer, then the steam speed will be about 3,6 m / s, which is fraught with locking phlegm in the dephlegmator and even spitting into the selection. In fairness, it must be said that such a regime is needed when obtaining alcohol and RPN in this case is not recommended for use.

The manufacturer, completing the on-load tap-changers, talks about the modes of operation of the device as a reinforcing column and does not aim for a product strength above 80-85%. What corresponds to the bulk of raw alcohol with a strength of 20-30% literally 1-2 steps of strengthening. This is quite achievable without a pre-suffocation regime. True, there can be no talk of serious cleaning. This mode is suitable for distillation of fruit and berry wine for further aging in barrels.

The reflux condenser “Bulat Bogatyr” still remained the bottleneck of the apparatus. Bulat had a dephlegmator with 4 tubes with a diameter of 10 mm – this is the outer diameter. With a length of 20 cm, the reflux condenser is capable of utilizing power up to 1200 W, but the steam speed is 4,5 m / s. Therefore, with the RPN, the pre-choke mode of the column is impossible. Changed to 5 tubes. What happened? Power increased by almost 20%. But the total cross section of the steam pipes changed by only 25%. The steam velocity at 1200 W was 3,6 m/s. Which is also a lot.

What needed to be done? Change not the number of tubes, but their diameter. For example, 4 tubes of 12 mm. This is insignificant, by 10 percent, would increase the power of the reflux condenser, but the steam speed would be reduced from 4,5 to 2,9 m/s. And this, although at the limit, would allow us to confidently work with the on-load tap-changer at pre-choking power. As for the SPN, with a power of 960 W, the steam speed would be approximately 2,3 comfortable m / s. The column would become almost exemplary BC. For a 2” column, the problem and solution are similar.

Refrigerators “Bogatyr” in the 1,5-inch modification can utilize up to 4 kW, and in the 2-inch version – up to 6 kW of heating power. The declared productivity of 7-10 l/hour of mash distillation is quite real. These are really good and powerful refrigerators. The product selection spout has a tube for communication with the atmosphere.

Modes of operation

This is a favorite topic of marketers when advertising devices made on clamp connections. And they are not particularly shy, wishful thinking.

If distillation in the “Pot-still” and “Fractional distillation without reflux” mode does not raise objections according to the declared performance, then something is clearly wrong with the “Distillation with reflux” mode without a nozzle.

The manufacturer claims that “Heavy impurities will condense and roll down the side in the form of phlegm, and the purified alcohol vapor will not linger in the dephlegmator.” Just a Christmas picture, touching crowds of trained impurities.

In fact, at the slightest fluctuation of the water pressure in the dephlegmator, all intermediate impurities concentrated at the top of the column will instantly fly into the selection. As for the fusel oil, due to the lack of a packing, the holding capacity of the surface of the column is so small that it will all be in the selection. And its concentration will even increase compared to the concentration in bulk. The resulting moonshine will begin to stink immediately after dilution to a drinking fortress. Columns of this type are contemptuously called fuselage generators for a reason.

“Classic rectification” is also a manufacturer’s fantasy. Without modernization of the apparatus, rectification to Bulat Bogatyr is impossible. It is realistic to get alcohol only by adding a few tsargs and replacing the on-load tap-changer with SPN. Moreover, due to the small sections of the steam pipes of the dephlegmator, it will be necessary to use SPN 3x3x0,25. The operating power for a 1,5” column will be about 800W, and for a 2” column it will be about 1600W. The steam velocity in the reflux condenser will be about 2,6-2,7 m/s. The average rate of “body” withdrawal will be depressing – about 600 ml/hour for a 1,5″ column and 1200-1300 ml/hour for a 2″.

The “Professional moonshining” mode, from the manufacturer’s point of view, is the use of a diopter and a mash bay unit. Also more than debatable. Diopter – decorates the column well, and sometimes it is even useful if a gross mistake is made and the foam climbed into the column or the upper choking began. But it has nothing to do with professionalism. A professional driver does not allow accidents, and the one who famously deals with their consequences is a mechanic.

As for the mash bay unit, the more impurities in the bulk, the larger the volume of packing is needed to keep them in the column and prevent them from being taken into the selection. With a stubby 45 cm column, you just need to weld this knot, or hang up the lock and throw away the key. Adding mash, and even more so raw alcohol during the distillation process, can bring nothing but harm to the quality of the product.

“Strengthening with subsequent expert aromatization” mode. One of the few modes worth using. Only it is usually called more simply: “re-distillation with aromatization.” And so – there are no objections. The genie basket is correct and the technology is correct.

In total, 27 modes of operation are announced, it makes no sense to consider them all. You just need to approach everyone with a certain degree of skepticism.

How to upgrade Bulat Bogatyr at minimal cost

The simplest and most progressive way is to purchase an alcohol selection unit in a corner outlet. This will allow you to remove the unfinished reflux condenser altogether and switch to a more comfortable and less capricious liquid selection.

For fans of the selection by steam, it can be recommended to replace the dephlegmator with a more suitable one in terms of characteristics.

There are more than enough manufacturers of the necessary nodes.

conclusions

- After the modernization of Bulat Bogatyr by the manufacturer at the end of 2018, the cube suffered more than other components. The use of the AISI 201 Chinese “Phoenix” pan as a base for the boiler, along with the disappearance of the safety valve, is a huge step back.

- Dephlegmators remained unfinished.

- The filler neck is an extremely dubious and expensive part.

In general, the apparatus is suitable for the production of aromatic distillate, and after a slight modernization and re-equipment, it is possible to obtain NDRP (under-rectified).

Reviewed by IgorGor.