Contents

“Alcovar Favorit” is one of the most successful models of moonshine produced under the brand name “Alcovar”. Popularity is facilitated by an affordable price and a complete set of high-quality cubes with a 2” clamp for connecting to the column. This opens up ample opportunities for further upgrades. In this review, we will analyze in order what this model can do, what are its advantages and disadvantages, what the manufacturer is cunning about and how the device can be improved at low cost.

Distillation cube

The manufacturer completes “Favorite” with Alcovar Compact cubes. These cubes are made of food stainless steel AISI 430, which determines the possibility of their use on any type of stoves.

The small thickness of the metal is compensated by the bottom stiffener and the conical top of the cube. At the same time, the main part of the bottom remains flat and suitable for use on induction cookers. The stiffening rib allows you to conveniently grab the cube when draining the stillage.

| Material | Food stainless steel AISI 430 | |||

| Metal thickness | day | 1,5 mm. | ||

| walls | 1 mm. | |||

| cap | 2 mm. | |||

| Flange hole diameter | 11 see. | |||

| dimensions | diameter | 30 see. | ||

| Height | 12 l. | 25 see. | ||

| 20 l. | 36 see. | |||

| Life time | Over 30 years. | |||

The geometric dimensions of the cubes make it possible to distill mash with a useful heating power of up to 3 kW without the risk of uncontrolled foaming. Naturally, this is true for sugar mash, fruit mash has its own characteristics.

Interestingly, the manufacturer did not give the full volume of cubes in the description, but rather the volume of the maximum bulk. This is a somewhat unexpected bonus. If you pour 20 liters of mash into a 20 liter cube, then its level will be slightly below the rib that separates the tank walls from the conical dome. The total volume of cubes is about 3 liters more than stated. That is, for a 12 liter – 15 liters, and for a 20 liter – 23 liters.

For the first stage in a 12 liter cube, you can pour not 8-9, but 10-10,5 liters of mash. In a 20 liter cube – not 13-15, but boldly 18 liters. When distilling raw alcohol, you can pour a nominal volume of 12 and 20 liters. To put it bluntly, the plus from the conical dome of the cube is palpable.

The disadvantages of distillation cubes include:

- lack of safety valve;

- bimetallic thermometer of low accuracy in the steam zone of the cube.

- lack of a drain valve;

- poor quality gaskets;

- a thin bottom determines the high probability of burning thick mash;

- the inability to install the heating element in the factory configuration.

Much is completed on their own, but in this case, what about the manufacturer’s warranty? Most buyers do not believe in any guarantees and, upon receiving the cubes, they throw the anachronistic thermometer into the trash and install the nipple under the electronic thermometer. Fortunately, the operation is simple and reversible.

With a safety valve and a drain, it’s worse, here the cube needs to be drilled and say goodbye to the guarantee. But if you carry a 20 liter tank, even conveniently grabbing the handle and the stiffener, health does not allow – you have to sacrifice guarantees.

Gaskets do not last long, they begin to crack, but they are always available and are inexpensive.

General characteristics

“Alcovar Favorit” is a classic column-type moonshine still with reinforcement. The distiller is made in the form of a monoblock. On the one hand, this led to its radical reduction in price, on the other hand, the only modernization that can be done is to install an additional drawer.

The apparatus consists of a drawer with a diameter of 50 mm and a height of 44 cm, in the upper part of which there is a fitting for a thermometer and a dephlegmator 20 cm long with an outer diameter of the shirt 63 mm. Next comes a steam pipe with a diameter of 12 mm, passing into a coil, which is placed in a jacket with a diameter of 50 mm. The manufacturer promises that the refrigerator is able to utilize 4 kW.

The productivity of the apparatus “Favorite” at the first stage is up to 3 l / h, and in the strengthening mode – 2 l / h.

Drawer and refrigerator

The drawer side with such dimensions can easily cope with spray entrainment during the first distillation with a useful heating power of up to 4,5-5 kW. This gives a large margin for the normal operation of the device. But here’s the refrigerator… The declared 4 kW can be utilized only in the seller’s imagination. Yes, and mash with such power will foam and run away from the cube.

The manufacturer quite rightly claims that the maximum capacity provided by the refrigerator is 3 l/h, which corresponds to a useful heating power of 1,5 kW. Taking into account the heat loss of the cube and the column, this is equivalent to the input power on the electric stove of about 2 kW, or taking into account the low efficiency of the gas stove, approximately the power of two gas stove burners.

But those who try to give 4 kW when distilling mash using a heating element or 3,5 kW on induction will be in for a surprise. A small 10 mm diameter steam pipeline will accelerate the steam to a speed of 30-40 m / s, which will create a significant increase in pressure in the cube. The experimenter will first hear a growing rumble, the hissing sounds of steam breaking through the gaskets, and if he does not stop heating in time, he will get unforgettable and very extreme adventures.

In accordance with the regulations, the maximum steam velocity in pipelines is allowed no more than 25 m/s. And the optimal (in terms of maximum intensity of heat transfer and stability of the process) is a steam speed of up to 20 m/s, which corresponds to about 2 kW of useful heating power for this apparatus. At higher heating powers, large-diameter steam pipes and multi-pass coils or shell-and-tube coolers are used.

In general, during the first haul, Favorit will perfectly cope with its tasks, providing productivity up to 3 l / h. Moonshine at the exit will be cold and slightly fortified. The conical dome and the empty, uninsulated side frame create conditions for partial condensation. This gives, albeit a small, but useful purification from non-volatile impurities. And don’t expect more from him.

In the second distillation, things are not so rosy. In the struggle for the degree of purification from impurities, the dephlegmator and nozzle become decisive.

The nozzle part of the tsarga is extremely small – 30 cm of the nozzle does not even allow one to think about fractional distillation. The maximum that they are capable of is to give some strengthening of moonshine, at the level of 1-3 steps, depending on the technology. That is, with 40% raw alcohol poured into the cube, you can get moonshine with a strength of 88 to 92% at the output. The degree of purification will be about the same as with standard fractional distillation.

To obtain better results, it is necessary to complete the apparatus with an additional drawer with a nozzle.

The manufacturer offers 30 and 50 cm drawers to choose from, 30 cm is nothing at all, and an additional 50 cm with a nozzle will correct the situation and create opportunities for selecting head and retaining tail fractions. Also pay attention to the quality of welding and seam finishes. In my opinion, this parameter does not raise questions.

Dephlegmator

A shirt-type reflux condenser on a 50 mm side is an extremely controversial decision. The heat transfer area with a length of 20 cm will be about 300 cm2. Specific utilization power for this type of dephlegmators is about 2 W/cm2. It will be possible to make the column work for itself with a useful heating power of about 600 watts.

This means that the mode of maximum separating power, which is typical for the operation of a BC or RC at pre-swallowing capacities, is unattainable for this apparatus. Even with an additional tsarga, only moderate purification from head fractions is possible, but alcohol cannot be made, and you still need to try to get into the GOST requirements for distillates.

There are objections that, by supplying an excess amount of water to the reflux condenser, it is possible to achieve dropwise selection even at much higher heating powers. Yes, almost right.

The problem is that the dephlegmator has the task of not only utilizing the steam entering it and letting its specified part into the selection, but also not overcooling the phlegm. The water leaving the dephlegmator must be hot. It is in this mode that the phlegm, flowing down from the reflux condenser, after passing the first centimeters of the nozzle, is heated to the boiling temperature and successfully participates in the processes of heat and mass transfer.

If you supply water in too large a volume, then the phlegm will seriously supercool. In order to then warm up to the boiling point, she will need to go down the column not a couple of centimeters, but 30-40 times more. And this entire area will be removed from full-fledged heat and mass transfer. And if the column is short? Phlegm will flow into the cube without participating in the process.

This is clearly seen in the strength of the product at the exit. If, in the presence of an additional side, it will be about 88% with 40% bulk, then this will mean that the steam has passed only 1 step of strengthening, 90% – 2 steps. What is there to talk about besides strengthening? Naturally, it’s not like alcohol, and you can’t get NDRF.

It is a low-power reflux condenser, which is also unsuccessful for a 2 ” pipe design, puts an end to this apparatus in the role of a beer column. But “Favorite” is positioned not as a BC, but as a moonshine with strengthening, we should not forget about this.

How to drive moonshine on Alcovar Favorit (instruction)

The first distillation does not cause difficulties – with the water supply to the reflux condenser turned off and without a nozzle. We distill at the maximum available power, remembering that you should not apply more than 3 kW.

The second distillation in the basic configuration:

- We slightly open the water supply to the reflux condenser, then by changing the heating power, we achieve drop-by-drop selection.

- We skip the stage of working for ourselves and stabilizing the temperatures in the column due to the absence of the column.

- We control the temperature of the water at the outlet of the dephlegmator. If the water is cold, then the power supplied is too high. A reflux condenser without reflux subcooling cannot stop the steam. We reduce the power and, by adjusting the water supply to the dephlegmator, we again achieve drop-by-drop selection. We control the outlet water temperature. The goal is to achieve a drop-by-drop selection, at which the temperature of the water at the outlet of the dephlegmator will be as hot as possible.

- We select “heads”.

- By increasing the heating power, we proceed to the selection of the “body” at the desired speed.

- Keeping in mind that the holding capacity of the nozzle is very small, we switch to the selection of “tails” at a temperature in the cube of 90-91 degrees, unless, of course, before that the nose tells you that the fuselage has already gone to the selection.

The second distillation with an additional side

In fact, it is no different, but the additional height of the nozzle will allow you to get more separation steps and separate the “heads” more clearly. The additional volume of packing keeps the fusel oil in the column up to a higher bottom temperature and makes it possible to switch to “tails” later. The product will be noticeably cleaner.

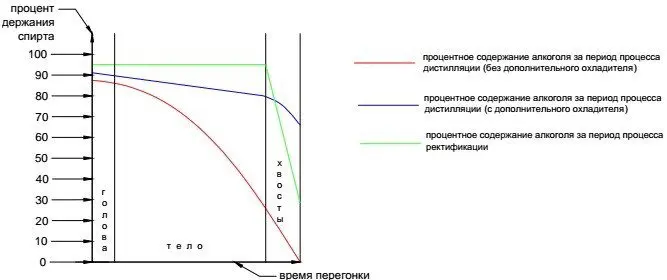

As you can see, the technology is very different from the technology of distillation on beer columns. This is not fractional distillation, but fractional distillation. During the distillation process, the strength of the product at the outlet will drop, which is a hallmark of fortified distillation.

If we talk about quality, then it will practically not be possible to get rid of the upper intermediate impurities, the “heads” will be less concentrated, they will have to be selected in a relatively larger volume.

The quality of cutting off the “tails” without an additional side is not much different from the results of conventional fractional distillation. During rectification, the strength of the “body” is always the same, because an alcohol buffer is created in the column, which cuts off tail impurities from the selection zone. During distillation with strengthening, impurities enter the selection during the entire stage. The use of an additional drawer side will somewhat improve the retention of “tails” and will allow you to achieve a more or less acceptable result for the distillate.

conclusions

Moonshine still “Alcovar Favorit” can be recommended to novice distillers as the first distiller, if they have chosen an evolutionary path of development for themselves. The apparatus is relatively inexpensive and can be used for both classical distillation and fortified distillation. On a completely normal cube, in the future, you can install a beer column.

For those who want to immediately receive a distillate of a high degree of purification, this kit is suitable, and even then with reservations, except perhaps a cube.

Reviewed by IgorGor.