An apparatus of such a high price category makes the heart of any true moonshiner freeze with forebodings – now I will finally get a well-made column without errors and childhood diseases in the design, I will find out how it should be in reality and, if desired, I can even expel pure alcohol. However, take care of your heart! Apart from the price, there is nothing else amazing in this product. Read more in our review.

Moonshine still “Midget 2017” is a constructor, from which, according to the manufacturer “Doctor Guber”, you can assemble a distillation column with a capacity of 1,5 l / h or a distiller with a capacity of 5 l / h.

The basic package includes two cap plates, a sight glass, a universal refrigerator, an alcohol extraction unit with a needle tap and a tubular mini-reflux condenser. You can choose from a classic cube with a ferromagnetic bottom or a cube with steam and water heating.

Stills

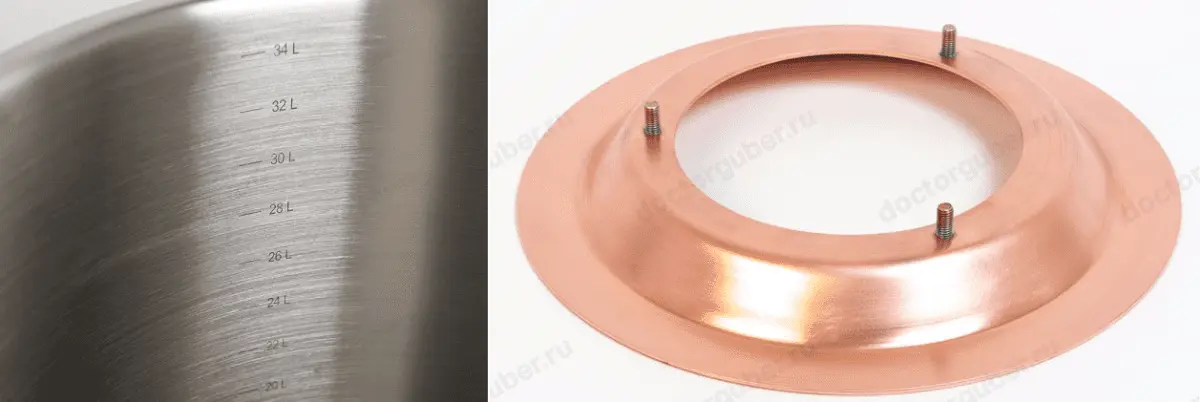

The cubes are available in capacities of 13, 21, 25 and 36 liters, with a diameter of 320 mm and a height of 160 to 450 mm, excluding the height of the conical lid. They are made of AISI 304 stainless steel. The bottom is three-layered – inside is an aluminum plate, outside is a ferrimagnetic layer. The stiffening rib on the side surface of the cube forms a protrusion inside, which serves to install a slotted sieve to filter the pellets.

Cubes can be equipped with a bard drain ball valve or a 1,5” clamp. The clamp allows, among other things, to install a butterfly valve for draining stillage. The conical cover is fastened with a clamp to the neck.

The neck of the pan is made with flanging, which provides more or less acceptable rigidity. This is vital, as the walls of this expensive pot are only twice as thick as a regular tin can! Their thickness is a miserable 0,7 mm. Even the famous “Luxstahl” is much thicker. But it cannot be sold for 14 thousand rubles, but the alembic “Doctor Huber” can!

The geometric dimensions of the cubes allow their use without the risk of uncontrolled foaming up to a heating power of 3,5-4 kW. Of the pluses, one can note the marking of volumes applied on the inner surface and the possibility of purchasing a copper cover, however, for a fee.

A flange made of stainless steel or copper with a diopter is installed on the cube lid with the help of three winglets; for some money, it is possible to additionally purchase a standard column support.

On the flange there is a nipple for an electronic thermometer. This is not important for the potstill mode, but for fractional distillation or rectification, I would like to have a thermometer in the liquid, and not in the vapor zone of the cube.

The cube is not equipped with a blast valve. Moreover, this is not an accidental oversight of the unfortunate designer, but a principled position. We quote a company representative: “We never put safety valves on traditional cubes, ever. This does not make sense, since the gaskets on the tank and on the flange do not hold more than 0,2 atmospheres, in the event of a flood, the cube will simply flow, the point is in the protective valve by 0,5 atmospheres if the tank leaks earlier! In general, do not fill more than 3/4 of the total volume into the tank when working with thick media and forget about the safety valve. This is not a pressure cooker, the safety of operation is ensured by the design at the design stage.”

A difficult case … Let’s start with the fact that the choking in the column occurs at a pressure of about 500 mm of water. Art., that is – 0,05 atmospheric. At this pressure, well-designed automation simply turns off the heating, considering it an accident. Moreover, just in case, there is duplication according to the readings of the thermometer located on the TCA (tube for communication with the atmosphere). It is considered not superfluous to have 2 different options for determining an emergency than to burn down an apartment once. But Doctor Huber does not even think of installing automation to protect the client.

When choking, the pressure in the cube will not reach 0,2 atmospheres, the gaskets will not leak, and the alcohol will simply splash out through the TCA, and it’s good if not on the gas stove. In this case, the safety valve and weak gaskets do not matter at all.

A safety valve is placed in case of blockage of the steam line in order to prevent damage to the cube and those very gaskets. To minimize the consequences of a possible emergency. This is a necessary element of equipment safety. If the gaskets squeeze out at 0,2 atmospheres, then this is a bad design, but the safety valve should still be, even if it is at 0,1 atmospheres. Everything else is from the evil one.

Column set

The set of the Midjet 2017 apparatus includes a pair of cap-shaped plates with a diopter, and the top plate is covered from above with an adapter from 3” to 1,5”. It is also possible to purchase additional components, as well as increase the number of plates to the desired level. After the last upgrade, this node is quite competently designed and implemented.

The designer “Midget 2017” has a shell-and-tube 275 mm refrigerator and a 125 mm dephlegmator. The rated power of the refrigerator in the presence of partitions would be about 2,7 kW, and the dephlegmator – about 1,4 kW. But since they are not present, the power is lower by about 10%. Refrigerator and dephlegmator have 4 steam tubes with a diameter of 14 mm. In this case, the unification was beneficial, as it allows you to collect them sequentially. In potstill mode, you can work with a 3,5 kW induction cooker.

The desire to unify everything played a cruel joke. A receiving cap is attached to the exit from the refrigerator, in fact a simple adapter from 1,5 ” to 1/2 ”, and a herringbone or parrot fitting to it, everything is on the clamps. But there is no tube for communication with the atmosphere on the cap. It turns out a very expensive set. Probably, it would be worth following the example of other manufacturers to make a cheap and already quite standard part. Much more elegant and functional.

Then you wouldn’t have to write in the instructions: “It is important that the silicone hose does not have kinks or rings. Otherwise, excessive pressure may form in the device, which will lead to its incorrect operation.

When assembling the designer, a drawer with a diameter of 38 mm by 32,5 cm with a Panchenkov nozzle, a 125 mm dephlegmator, a 135-degree outlet with a nipple for an electronic thermometer and a 45-degree outlet, a refrigerator and the same monstrous tandem – a receiving hood are used as a distillation column plus a tree. Naturally, with the same warnings in the instructions.

In this form, it is a beer column with a Panchenkov nozzle of 32 cm tsarga with a diameter of 38 mm and two cap plates at the bottom of the column. Knowing the power of the reflux condenser and the throughput of the column, one can easily estimate that it will give a performance of about 1,4-1,5 l / h. Which, however, coincides with the manufacturer’s statements. The distillate at the outlet will be fortified, but a good degree of purification is not worth mentioning. The holding and separating capacity of this column is very low. But, nevertheless, this mash column is capable of slightly combing the distillate, reducing the concentration of head and tail impurities.

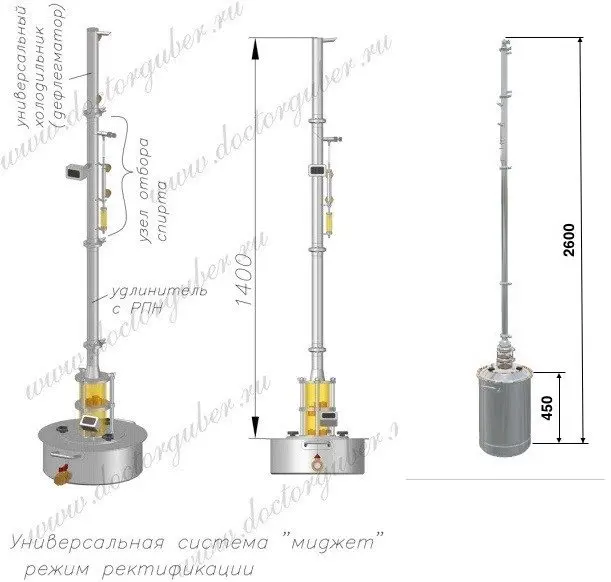

An attempt to depict a distillation column by adding another extension with a liquid sampling unit and an on-load tap-changer nozzle with a total length of 450 mm causes only a sad smile. Well, even if the height of the nozzle in this extension is 30 cm, in total we get 60 cm of the tap changer nozzle and 2 physical plates at the bottom of the column. It’s definitely not a rectification.

About 10 steps of strengthening can give 95-96% of the fortress and will allow you to slightly clean the moonshine from head impurities, and if you follow the right technology, slightly hold the sivuha. But alcohol is out of the question. It’s just a publicity stunt.

For a more or less clear separation of the “heads” you need at least 1 meter of nozzle. Having installed a shell-and-tube refrigerator as a condenser on top of the column, and stating that it could also be built up with a reflux condenser, the manufacturer proudly declared that the height of the column was 1400 mm, and with an additional reflux condenser and a receiving hood with a herringbone as a TCA, in general 1,6 meters.

“Doctor Guber” confused the height of the column of 1,6 meters with the height of the packing part of 1,5 meters required for the production of alcohol. Unless, of course, the nozzle is SPN. For RPN, this is not enough.

If the Midjet 2017 apparatus is supplemented with a 700 mm long drawer to increase the nozzle part to at least 1,3 meters, then the height of this column will be 2,1 m. about 10 cm. Well, a cube of 25 or 36 liters in height from 40 to 45 cm, and with a conical lid, 5 cm will be added.

Total we get 2,6 meters in height. Where can such a column be placed? Of course, on an induction cooker, which will add another 15 cm of height, which we lacked so much. The use of a 45-degree bend will obviously not solve the issue, only a 3-meter ceiling is needed.

The completely unfortunate ratio of the height of the packed part to the total height of the column makes it almost impossible to assemble a full-fledged distillation column for use in a standard apartment.

In addition, the sides and the cube are not insulated – what kind of alcohol are we talking about? Wild Phlegm will mix everything in the column, breaking the division into factions. In the steam zone of the cube, with a decrease in alcohol content, more reflux will begin to condense, which will reduce the amount of steam entering the column by more than 10%. This will spontaneously reduce the reflux ratio in relation to the set one. As a result, intermediate impurities will be in the selection, however, not much ahead of the fusel.

Automation and control devices

The proposed rectification control unit (BUR) is a thermostat from those that are installed on incubators, only 10-20 times more expensive. The situation is also aggravated by the built-in temperature probe, which tightly fixes its location in the thermometer nipple next to the sampling unit. When the temperature rises by more than a predetermined value, it simply turns off the valve located under the adjusting needle valve of the extraction unit.

Firstly, when the temperature rises at this level by 0,2 degrees, this will mean that intermediate impurities have already entered the selection and the fuselage has also begun to break through there. That’s not how alcohol is made. Even if there is one temperature sensor, then it must be placed at the entrance to the column – 20 cm from the bottom of the nozzle. This will make it possible to catch the moment of depletion of the alcohol buffer much earlier and react in time.

Secondly, imagine that atmospheric pressure has changed, by a little – only 4-5 mm Hg. pillar. It was 760, but it became 756. Really? And at this time, the impurities went into the cube, and the temperature should have risen by 0,2 degrees, is that also realistic? Events offset each other. The temperature on the sensor fluctuated up and down and remained in place. Impurities rod in the selection, but the BUR does not react. And it will not respond until the temperature of the sensor rises another 0,2 degrees, unless, of course, the atmospheric pressure continues to fall.

That is why, during rectification, everyone abandoned this method a long time ago and work according to other methods that exclude the influence of atmospheric pressure. BUR is an obsolete technology, not worth even a tenth of the asking price.

The next aspect of normal rectification is stable heating power. In this regard, the manufacturer did not go further than the thyristor regulator. This is acceptable for distillation, but rectification requires stabilization of the input voltage. Appropriate automation is required. Apparently, this aspect was left as homework for buyers.

conclusions

In general, with the help of the Doctor Huber constructor, you can assemble an operating distillation column. But from those parts that are included in the standard package of the Midjet 2017 device, this will not work.

Despite the good quality of welds and their processing, as well as the quite decent level of calculation of individual structural units, Midget-2017 remains just a moonshine still with the possibility of transformation into an ordinary distillation column with liquid or steam extraction.

Reviewed by IgorGor.