Apparatus “Mendeleev” designed and manufactured in Chelyabinsk. The manufacturer gives a 3-year warranty for products and a year of free consultations on all issues related to their operation. Columns and cubes are sold both as a set and separately. At first glance, the devices create a good impression, and the official website is beautiful and non-standard. Information about product characteristics is available, making it easy to compare and make a choice.

Stills

A rare case when the manufacturer did not remake another Chinese pot, but offered the author’s version of the alembic. The design and equipment of cubes with a capacity of 14, 25 and 37 liters is the same.

| Volume, l | 14 | 25 | 37 |

| Height, cm | 31 | 41 | 58 | |

| Bottom diameter, cm | 27 | 31 | 31 | |

| Neck diameter, mm | 80 | 104 | 104 |

Based on the diameter of cubes, we can say that for a 14 liter cube, the allowable heating power during the distillation of mash without the risk of uncontrolled foaming is 2-2,5 kW, and for 25 and 37 liter cubes – 3-3,5 kW, which corresponds to their maximum bulk and from this point of view they are balanced.

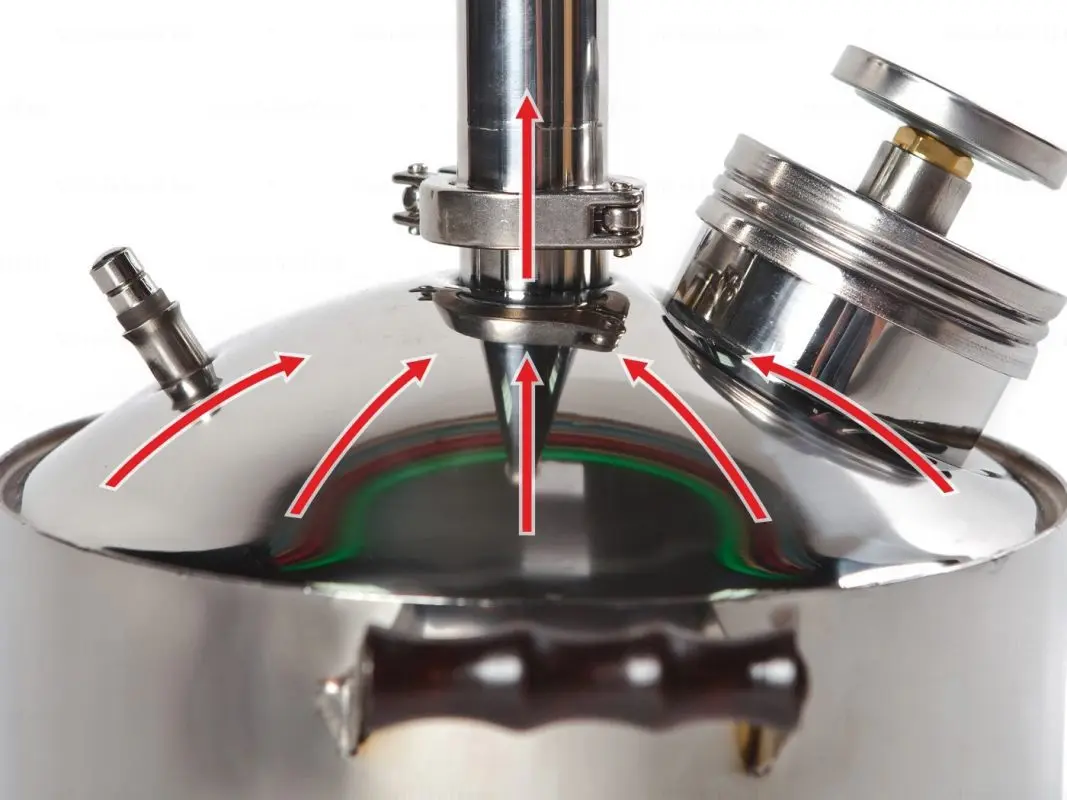

Cubes have a spherical top surface, which is a definite plus. This creates an additional zone for quenching the foam, allows for better distillation and creates the necessary rigidity for attaching the column.

Wooden handles, a fitting, a bard drain valve and an original overpressure relief valve can also be attributed to the advantages.

And now for the bad. First of all, the thickness of the walls and bottom is 1 mm, it’s not even funny, just a tin can. For sugar mash, it will still somehow pass, but for what it is thicker – a problem that requires considerable skill and various tricks from the owner of the apparatus in order to avoid burning.

The bottom of the cube is made of ferrimagnetic stainless steel. This allows the use of induction heating. Stiffening ribs to some extent compensate for thermal stresses during uneven heating on gas and prevent the occurrence of residual deformations. A thin bottom is a well-known problem for manufacturers, with the consequences of which they courageously fight.

A bimetal thermometer with an accuracy class of 2.0 and a scale of up to 120 degrees, by definition, has an error of 2,4 degrees. Placed in the steam zone, it measures the temperature not of the boiling vinasse, but of the steam. The steam, rising from the boiling surface to the cap of the neck of the cube, is continuously cooled from the boiling point, down to the condensation temperature. For pure liquids – water or steam, this difference is negligible, but for their mixture at boiling temperatures from 90 to 97 degrees, it is noticeable. In addition, the lid and neck act as a large radiator that cools the massive thermometer sleeve. In general, if the boiling point of the mash is 94 degrees, then what the thermometer readings will be is a question for a qualified psychic, and not for a distiller.

The neck of the cube deserves separate criticism. If earlier it was sharp, now the manufacturer decided to fix it and bent its edges inward. The sharpness of the edges has not gone away, just before you could scratch yourself by putting your hand into an extremely narrow throat, and now by sticking it out. Brilliant solution!

The threaded connection of the cap with the neck is an ambiguous solution, even a rather large thread does not guarantee that hot jamming will not occur. On the contrary, together with a soft silicone gasket, such a connection creates an uncertainty in the degree of tightening. A little weaker and there is no tightness, but if you reach it hot, you will have to unwind it with a tool.

As for the configuration of the cube, the lack of the possibility of installing a clamp under the heating element, adjustable legs and a pressure sensor should be noted as serious shortcomings. Without these “trifles”, statements about the use of Mendeleev apparatuses as distillation columns, even with additional tsargs, will cause nothing but a condescending smile from experienced distillers.

And finally: the steel grade from which the cube is made is not advertised on the official website for some reason. The conclusion is simple: there is nothing to brag about, we assume the worst of the options. It’s a pity.

Columns “Mendeleev”

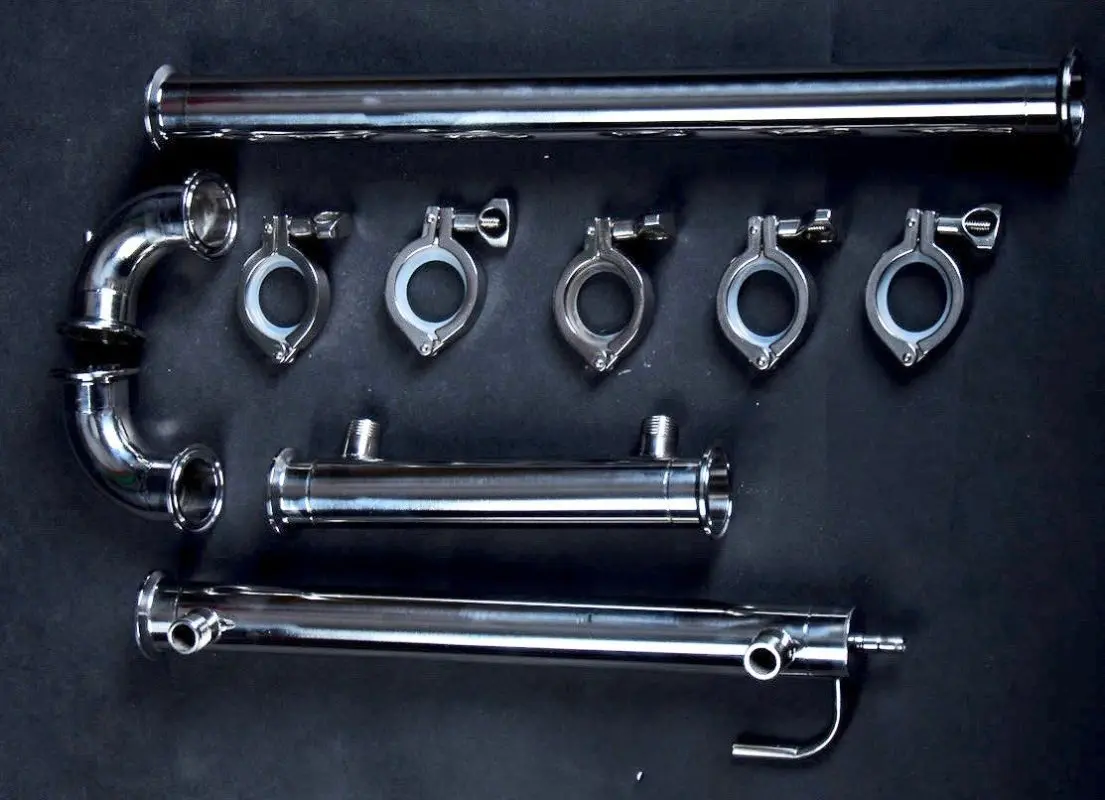

There are three versions of the device: one and a half inch “Standart” and “Plus”, as well as a two-inch “Pro”.

Standart

The “Standart” version is the simplest and most budgetary; at the request of the customer, it can be additionally equipped with a clamp connection in the arch. This allows it to be used in potstill mode.

The height of the tsarga is 50 cm, which is enough for moonshine, but extremely small to contain the fuselage and obtain distillates with an acceptable degree of purification.

A reflux condenser and a jacket refrigerator with an internal diameter of 25 mm, a height of 20 and 35 cm, respectively. This makes it possible to utilize the useful power of 1,6 kW for the refrigerator and 1,2 kW for the dephlegmator, which corresponds to the power of the gas burner, for which, apparently, the apparatus was developed.

When working with an on-load tap-changer, it will be problematic to achieve pre-choking power in the self-operating mode and to select drop-by-drop “heads” due to steam slipping through the dephlegmator at the slightest fluctuations in water or gas pressure. And the shirt design of the dephlegmator does not provide for the centering of the flow of phlegm into the nozzle. It will flow down the walls of the pipe, slightly wetting the nozzle, while the steam will rise along the center of the tsarga, which is the most free from phlegm. Thus, the separating ability of the column will make it possible to obtain only fortified moonshine.

In distillation mode, a capacity of up to 3 l/h can be expected. Well, the 6 l / hour promised by the manufacturer can be attributed to the fantasies of marketers.

Plus

The “Plus” version of the device is designed for more powerful sources of external heating and differs from the “Standart” only in complete disassembly, the use of a shell-and-tube cooler and a dephlegmator with 5 steam tubes with an internal diameter of 8 mm. The refrigerator in the nominal mode is able to utilize power up to 2,5 kW and show productivity when distilling mash up to 5 l / h. With more power, moonshine will come out hot.

The dephlegmator can utilize power up to 2 kW, but with an operating power for on-load tap-changers of 1200 W, steam will accelerate in its tubes to excessive 3,6 m / s, as a result, conditions will be created for overhead.

When using SPN and operating power up to 960 W, the steam speed will remain within 2.9 m/s. Selecting qualitatively “heads” in this mode will be problematic, but real.

Raise questions and 2 partitions inside the dephlegmator. Usually an even number of partitions are placed to separate the inlet and outlet of the cooling water in different directions, an odd number – in one direction. Here we have 2 partitions and water supply fittings located on one side, which means that the second partition along the water course does not carry a useful function, but only contributes to the creation of stagnant zones.

Banco Pro

The “Pro” version of the device, in addition to a diameter of 2 inches, is distinguished by a large number of steam tubes – 7, an additional drawer in the basic configuration and a “head” selection unit.

Refrigerator with 5 partitions and 7 steam pipes with an inner diameter of 8 mm can utilize up to 3,5 kW of useful power and provide a productivity of up to 7 l / h when distilling mash.

A dephlegmator with 2 baffles and 7 steam pipes with an inner diameter of 8 mm is more than sufficient in terms of its power. But the speed of steam in its tubes at an operating power with an on-load tap changer up to 2200 W will be 4,7 m/s. When using SPN and operating power up to 1800 W – 3,8 m / s.

At such speeds, the phlegm steam will be driven up the tubes and literally bubbling on the upper tube plate, creating all the conditions for choking. There can be no question of serious purification of the distillate or obtaining alcohol, even with an additional tsarga.

A typical and very annoying mistake. It is enough to change the diameter of the steam pipes by 12 mm and you would get a good beer column with a steam speed of 1800 m/s at 2,5 W and 2200 m/s at 3 W.

But the manufacturer is not looking for simple ways; to overcome problems, a glass-type “head” selection unit is included in the basic package.

The growth of knowledge of home distillers and the understanding that in order to obtain high degrees of purification it is necessary to work at pre-choke capacities made this knot quite fashionable. A kind of crutches for a poorly calculated dephlegmator.

True, its use has a bonus: when selecting “heads” it is easy to maintain a constant speed. However, this does not solve the issue of working at pre-suffocation capacities during the selection of the “body” and limits the capabilities of the apparatus to obtaining fortified moonshine.

conclusions

- Apparatus “Mendeleev” are column-type moonshine, designed to produce fortified moonshine, and cope with this task. But no more. To meet the level of requirements of modern mash columns, all models require serious improvements.

- The design of distillation cubes is sharpened for heating on a gas stove and working with sugar mash. Cubes are not intended for grain and other thick mash.

- As the main disadvantages of cubes, it is worth highlighting a too thin bottom, lack of preparation for a heating element, a non-informative bimetallic thermometer and the inability to adapt to the rectification technology.

- Obtaining a good degree of distillate purification is practically impossible due to the high steam velocity in dephlegmators when the columns are operated in the mode of maximum separating capacity at pre-choke capacity.

- The quality of the welds and their processing are average, this is obvious even from the advertising photos on the site.

- Automation of processes remains outside the interests of the manufacturer.

Reviewed by IgorGor.