All three devices are based on the Geyser dephlegmator, manufactured by the Thermosfera company in 1,5 and 2 inch versions. The differences between the reflux condensers are minimal and concern only the configuration of needle valves, aftercoolers and drawers with different options. Having bought the simplest option – “Geyser Classic”, over time, you can improve the device to your taste, up to the distillation column. In this review, we will look at the features of the line.

Stills

All moonshine stills “Geyser” Termosfera supplies with distillation cubes, which are described in detail in the article on moonshine stills “Istochnik” of the same manufacturer.

We will not repeat ourselves, but we will immediately move on to the heart of these devices – the dephlegmator, or more precisely – to the condenser, since it is designed for complete, 100% condensation of the steam entering it, and does not divide the steam into two types: condensed and passed further into the selection.

Capacitor Geyser

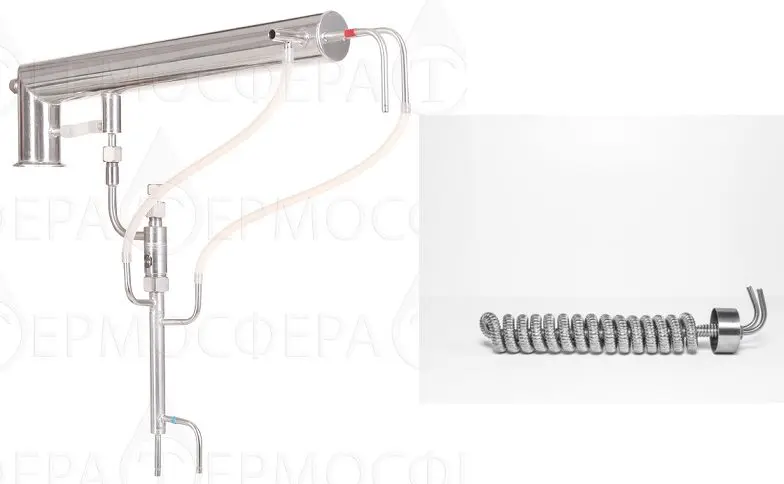

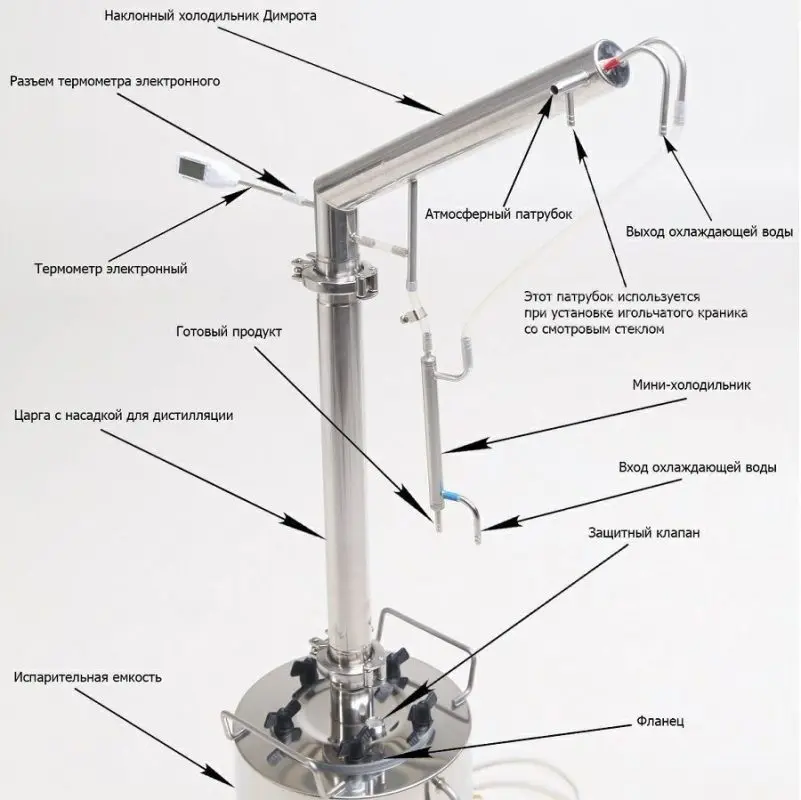

In appearance, the Geyser capacitor is a standard “stick” with a Dimroth refrigerator inside. Overall dimensions: height 125 mm, length 430 mm. Equipped with a thermometer nipple suitable for probes with a diameter of 1; 5; 4 and 6 mm.

Tubes with a diameter of 8 mm were used to exit the product. The two-inch version, in addition to the size of the clamp, differs in design by supplying water through ½-inch threads welded to the tubes.

The basic version can be equipped with an aftercooler or a needle tap with a sight glass complete with an aftercooler. And the prices, to put it mildly, bite. With a dephlegmator price of 6500 rubles, the manufacturer offers to pay another 20 rubles for a needle valve with a short 6000 cm aftercooler. Doubtful pleasure.

The justification of the price by the ultra-high quality of the needle tap may impress someone, but more or less experienced distillers know that you can get these little things from other manufacturers. For example, on the site of a competitor of Thermosphere, a standard and familiar needle valve costs 520 rubles, and a full-fledged 40 cm aftercooler costs 1300 rubles (Thermosphere offers a similar one for 2800 rubles). All prices are current as of the end of January 2019.

The miracles don’t end there. Reading the description of a 1,5 ”capacitor, you stumble over the declared power: “Complete condensation of vapors up to a power of 4000 W (alcohol) and 5000 W (during the distillation of mash)”. What’s this? Not believing our eyes and deciding that this is an ordinary typo, we look at the description of a 2 ”capacitor, and we see even more impressive promises: “A huge performance margin. Work with powers from 1 to 10 kW. It looks especially funny together with the final phrase of the condenser description: “If you plan to make a withdrawal of more than 1 l / h, then it is advisable to connect an additional aftercooler of 400 mm, otherwise the output product will be warm.”

And then what to do with the advertised withdrawal rate of up to 12 l / h for a 1,5 ”model, or 30 l / h for a 2-inch one? What additional to connect?

The lack of a clear description of the dephlegmator design leaves a wide field for fantasies and assumptions. However, the host of the channel “Master-Alkomaster” Dmitry destroyed the intrigue. To a direct question about what kind of magic dimrot is inside the condenser, what is its length and the diameter of the tubes, he directly answered: “The dimrot is made of a corrugated pipe. In this design, in principle, the diameter and number of turns are not as important as the power to be deposited. 6 kW – upsets calmly.

A rather strange and unusual solution for the “heads” of the RK and BC of domestic production, but in Poland they are found all the time. Yes, indeed, such columns are distinguished by a large utilized power and ease of manufacture. Despite this, they are rarely used. The main arguments of opponents of the use of corrugated pipes boil down to the fact that during rectification, the corrugated surface well retains and accumulates head fractions, it is difficult to wash them before selecting the “body”.

In addition, the relatively large cross section of the corrugation with a low water supply leads to its airing in the descending sections. Increasing the water supply solves this problem, but supercools the phlegm. We have to look for a compromise, which is possible if the corrugation diameter does not exceed 10 mm, and is extremely difficult for large diameters. For distillation and beer columns, most people prefer the more reliable and traditional version of the Dimroth refrigerator – stainless steel pipe 6 x 1 or 8 x 1 mm. Moreover, the latter is mainly used for autonomous cooling systems.

Let’s not forget that Dimroth’s task is not to ensure maximum heat transfer, but to drain the condensate through an increasingly hot pipe towards the steam that heats it. The return of phlegm to the column is maximally heated and ready for re-evaporation in the process of heat and mass transfer. The use of a corrugated pipe, and even in combination with an inclined condenser, does not contribute to this goal in any way.

The phlegm supercooled by 40-50 degrees not only disables the upper part of the nozzle, forcing it to work to heat the phlegm. For example, during the selection of “heads”, 15-20% of the steam, heating up the phlegm, will condense below the selection zone and will not carry head impurities to it. These impurities will flow down the column, then re-evaporate and will enter more and more meaningless coils. During the selection of the “body”, supercooling will lead to a reduction in the height of the nozzle involved in the separation process, since its upper 20-25% will simply heat up the phlegm.

However, disputes about the applicability of corrugations for dephlegmators do not subside. Proponents point to its successful use in beer columns with independent cooling systems. With the help of simple devices, they provide water supply with a temperature of up to 40-45 degrees, significantly expanding the condensation zone and successfully combating phlegm hypothermia. Well, in the case of the Geyser, we can say that it was the corrugation that allowed it to become universal and be used both in the distillation of raw alcohol and in the distillation of mash.

Geyser Classic

The standard Geyser dephlegmator, equipped with a small 30 cm drawer and an on-load tap, became the Geyser Classic moonshine still. It allows you to distill mash with a capacity of up to 2 l / h and receive fortified moonshine at a speed of up to 1,2 l / h during fractional distillation. If the owner has a desire to get alcohol, he needs to purchase an additional drawer of 600 mm with an SPN nozzle, which is directly indicated by the manufacturer. In the base, the device is equipped with a mini refrigerator and a small faucet to control the selection rate.

In the description of the devices, the data on their performance are much more modest and, apparently, closer to the truth than in the descriptions of the dephlegmators.

Geyser Lux

Equipped with a glass four-plate capped column, the Geyser Classic turns into a Geyser Lux. This kit is designed to produce aromatic grain and fruit distillates.

The column has a wide range of operating heating powers – from 0,6 to 2,5 kW, which determines the possibility of its successful use on any heating sources. What is called – even at the stake. Well-designed and well-manufactured capped trays are highly efficient and provide a quality distillate. One of the major advantages is the possibility of extension to the required number of levels. Not buying another one of the same column, namely, increasing the number of plates to the required number. This allows the distiller to choose the degree of purification of the distillate to his liking, without spending extra money.

Kits are available to increase the height of the column by 2, 4 or 6 levels. By setting an additional 6 levels, you can get a drinking quality distillate that does not require aging in a barrel.

“Geyser-Lux” is a productive column. With an internal diameter of 65 mm, it provides a capacity of up to 2 l / h when collecting the “body”. Although in fact it is capable of more with the appropriate heating power and configuration with a cube of the 2018 model.

On such a column, it is possible to work with much higher powers than the manufacturer’s recommended 1,5 kW. This limitation arose due to the use of some cubes of the 2008-2017 model range, which have too small a diameter or height.

For a normal boiling process without excessive uncontrolled foaming, the heating power is limited to 4-5 watts per square meter. see bulk mirrors. For example, for the popular 18 l cube model with a bottom diameter of 235 mm, this is only 1,7 kW. It is clear that with a column operating up to 2,5 kW, this cube does not fit in one set.

Distillation column F43

To obtain a distillation column, the manufacturer suggests using the Geyser dephlegmator in the maximum configuration – with a needle tap with a viewing window and a short aftercooler assembly.

To ensure good performance, we offer 2 drawers of 600 mm each with an SPN 3,5 x 3,5 nozzle and a diameter of 38 mm instead of 43! This increases the design capacity of the column by 30%. The total height of the column, as it should be according to the classics, is equal to 30 internal diameters of the column. One of the drawers is equipped with a nipple for a thermometer to control the process. As desired, it can be placed at the bottom or at the top, getting a control point on 1/3 or 2/3 of the column.

Actually, if we take an aftercooler and a needle valve on the side, then apart from these two tsargs, nothing distinguishes the F43 distillation column from the Geyser Classic. It is also not worth talking about thermometers, their price is a record one in today’s market. You can buy cheaper at times not with the worst characteristics and capabilities.

The column is capable of producing “Extra” class alcohol at a declared rate of up to 1,2 l/h. Only this is not the performance of the column, but the starting speed of the “body” selection. As the “tails” approach, the power will need to be reduced by 2-2,5 times. Let this not be a surprise. An easy and forgivable publicity stunt.

For all other characteristics: declared 2500 ml / hour of 95% alcohol, 3500 ml / hour of distillate and 10 l / hour of raw alcohol, there is nothing to say. Let it remain on the conscience of the manufacturer. We only note that in these modes the operation of the distillation column is no different from the Geyser Classic. Same hardware, same performance. And the declared rate of obtaining distillate for “Classic” for some reason is up to 2000 ml / hour. Probably, it is worth believing more modest figures.

conclusions

- The production quality of the Geyser devices is at its best, but the equipment from the additional configuration is relatively expensive.

- Controversial characteristics in terms of power and performance in the description of the devices raise questions. It is worth trusting smaller values, because they more adequately correspond to the parameters of columns and cubes.

- Due to the high power of the Geyser devices, it is better to complete them with distillation cubes from the Thermosphere of the 2018 model range.

- The instructions and video tutorials accompanying the devices are well-executed. A cursory study of them is enough to start the successful operation of the equipment.

- In general, “Geyser Classic”, “Geyser Lux” and RK F43 are efficient devices that allow you to make almost any drink at home.

Reviewed by IgorGor.