Contents

The new apparatus “Soyuz” from Gainutdinov A.N., manufactured at the production facilities of the enterprise in the city of Kirov, immediately aroused genuine interest among distillers. Quite vividly discussed are its differences from its predecessor, in which direction the development is going, and so on. In this review, we will evaluate the technical characteristics of the product.

Distillation cube

Compared to the previous version, the cube has undergone a major upgrade. The 3mm thick lid is traditionally equipped. Clamp for installation of the column, bimetal thermometer and overpressure relief valve from the pressure cooker. Fastening to the cube is carried out with an adjustable stainless steel clamp through a U-shaped silicone gasket.

The problems here are obvious and have been discussed many times. A thermometer in the steam zone with an accuracy class of 2,5 and a thick sleeve does not allow to determine with sufficient accuracy the current boiling point of raw alcohol in the range of 92-98 degrees, which means it cannot be useful in determining the moment of transition to “tails”. The only joy from such a thermometer is to understand when to complete the process when distilling the mash. You can read more about this in the article on the right thermometer for the cube.

As for the hackneyed topic of the safety valve, it is worth recalling that the maximum danger comes from the cube during its sudden depressurization at a pressure of more than 0,5 atm. In a small room, this will lead to the instantaneous creation of an explosive concentration of alcohol vapor and it remains to wait for the slightest spark. And it doesn’t matter how it happens: the collar will be torn off or some bad person will unfasten its latch. A strong and reliable stainless steel clamp can protect against the first option, but no one is safe from stupidity.

The handles of the cube have received additional reinforcement by spot welding, now you can not be afraid that they will loosen over time on large cubes and present a hot surprise to the owner. This is a big plus.

The output under the heating element is standard for cubes above 21 liters. The insert is made in the form of a thread inside the tank. The solution is quite rare, but interesting. In combination with a stamped flat area on the cube, it allows you to seal the connection with a simple silicone gasket without bothering with kilometers of fum tape.

In the base, the cube comes without a heating element, in its place there is a stub. The heating element can be purchased complete with a smooth power control unit. Or take from another manufacturer complete with automation. The second option will be required if you are seriously engaged in rectification, since the proposed automation does not have output power stabilization.

The cube has a zigovka under a sieve (false bottom), which expands its capabilities in terms of working with thick mash. The sieve is bought additionally, but really worth the money. Made with high precision and very thoughtful. The spiral arrangement of the slots and the support along the entire perimeter on the ledge of the bead, in combination with a thickness of 1,5 mm, ensures real rigidity of the entire structure.

The stillage faucet still makes me smile. Who came up with and why kept this design? A conventional straight valve is much more convenient to use. Try it when the 50 liter pot is on the floor with a fully assembled ceiling height column. First, lift the cube on a stool, and then drain … Not a bad relief for the back.

However, all this is trifles and an object for the application of ingenuity and hands. Against the background of competitors, the cube looks more than worthy and deserves the attention of potential buyers both in a set with a column and on its own.

Brazhnaya column “Union”

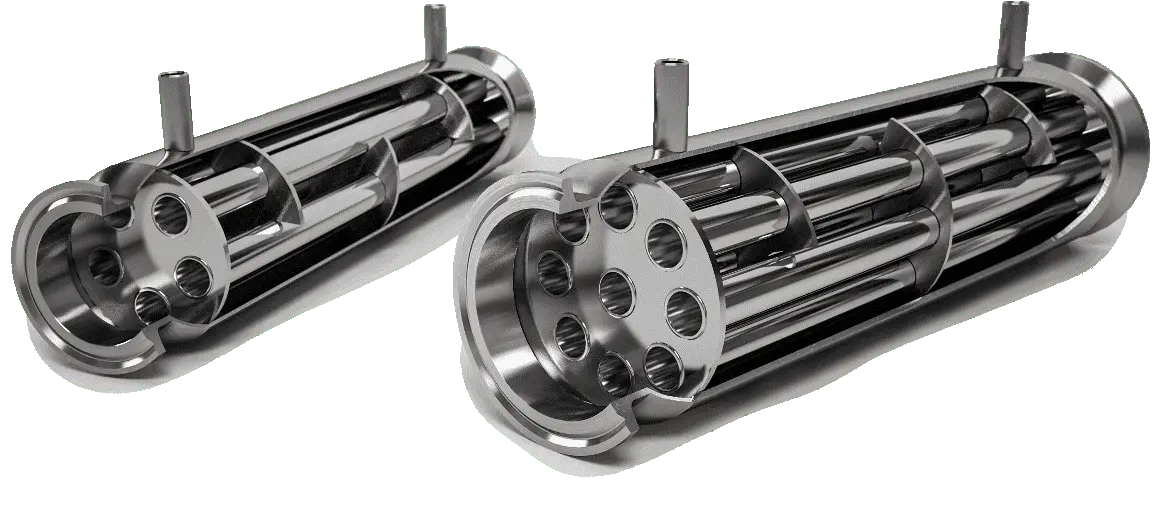

The devices are available in 1,5” and 2” versions. By their design, these are classic BCs with a selection of steam after a reflux condenser. Let’s check the compliance of the declared characteristics with reality and the requirements of heat and mass transfer technology.

Refrigerator

For the one and a half inch version, a refrigerator is offered with a length of 500 mm, with 5 channels with a diameter of 10 mm. The declared utilization power is 4,5 kW and the productivity during the distillation of mash is up to 8 liters per hour. Given the heat loss, this is true. The refrigerator is able to utilize up to 4 kW of useful power in the nominal mode and provide a starting capacity of up to 7 liters / hour when distilling mash. If the moonshine at the exit is warm, then it’s really possible to reach 8 l / h. However, even without this, the characteristics for a 1,5 ”BK refrigerator are very worthy.

For the two-inch version, a refrigerator is offered with a length of 500 mm, with 9 channels with a diameter of 10 mm. Claimed utilization power is 6,5 kW and productivity during the distillation of mash is up to 10 liters / hour. And here the manufacturer is even modest. This refrigerator is capable of more. 6 kW of useful power is too tough for him even in nominal mode, if necessary, he will eat much more. I would not be surprised if this refrigerator, on real tests during the distillation of mash, will give out up to 12 liters / hour at the start.

In general, refrigerators are made with a good margin of power. The presence of a tube for communication with the atmosphere and a rather deep receiving glass enable stable operation in all necessary modes, including potstill.

Refrigerator partitions provide structural rigidity and the absence of “spotting” during its operation. Partitions do not seriously affect the efficiency due to the large distance between them, although there is no need for this.

Dephlegmators

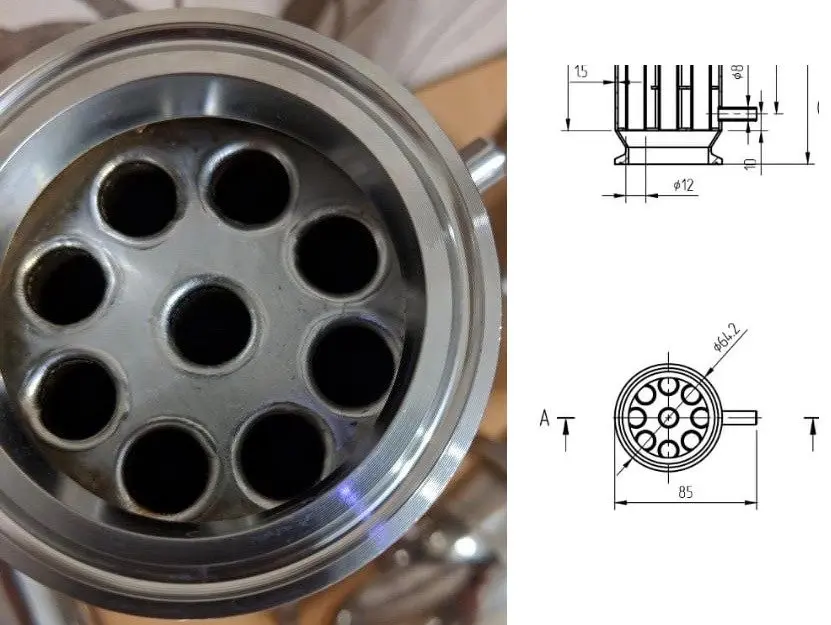

For 1,5” and 2” columns, reflux condensers with a working height of 200 mm with steam tubes with an outer diameter of 12 mm are offered, in the amount of 5 and 9 pieces, respectively.

Well, about the main thing – the power and speed of steam. So, a 1,5” column, when working with an on-load tap-changer, has an operating power of approximately 1.2 kW, and a steam velocity of 2,3 m/s. A 2” column with on-load tap-changers has an operating power of approximately 2.2 kW, with a steam velocity of 2,3 m/s.

Excellent result. The stability margin is at least 20%. As of April 2019, this is one of the best indicators on the market.

In discussions on the forums, the question often arises that the reflux condenser is placed in a pipe of a larger diameter. Due to this, the proportion of phlegm flowing down the walls may increase. Fears are logical, but caused, rather, by the pictures on the site.

If you look at the drawings or real photos of the reflux condenser, it becomes clear that this is a far-fetched problem, since the overlap area is insignificant. Yes, and the foam zone between the reflux condenser and the nozzle will average out the flow of reflux over the section of the column, so the question of the need to use a reflux concentrator will not even arise.

The presence of baffles in the reflux condenser makes it possible to reduce the speed of the cooling water and increase its average temperature. This has a positive effect on the degree of supercooling of the phlegm returned to the column.

Tsarga

For both modifications of the device, the height of the drawer side is unified and is 450 mm. Quite logical: 4 on-load taps and 5 cm of empty space in front of the dephlegmator. To obtain a fruit or grain distillate with a little cleaning for aging in a barrel, as well as for the distillation of mash, the base tsarga is more or less enough. True, the nozzle is not included in the basic configuration, it must be purchased additionally.

This is not enough to obtain NDRF, and the manufacturer recommends purchasing an additional drawer and SPN for these purposes. Again, logical and without deception. To contain the fuselage in the column, you need a place, and there is nowhere to get it from, only to increase the volume of the nozzle.

Workmanship

Best of all, the quality of manufacturing is indicated for the first time by the opportunity to download assembly drawings of devices from the official websites of the manufacturer. Please: download, purchase components, cook in your garage. And then compare the result with the original, calculate your costs and honestly answer the question: “Was it worth it?”.

Yes, the manufacturer does not lack self-confidence, and it is well deserved. Since the time of the first “Bogatyrs”, the quality of welding seams and their processing has remained at a decent level. An example in the photo.

conclusions

- The moonshine still “Soyuz” in 1,5 “and 2” modifications has the right to be called a full-fledged mash column and can be recommended for purchase.

- Among the shortcomings of the equipment included in the basic package, it should be noted a bimetallic thermometer in the steam zone and a bleed valve from a pressure cooker that does not ensure safe operation, as well as a rather controversial vinasse drain valve. But still, Soyuz cubes remain among the best on the market.

- Refrigerators and dephlegmators are well thought out constructively, are of high quality and do not need to be finalized.

Reviewed by IgorGor.