Contents

The hydromodule for mash is the proportional ratio of sugar (in kilograms) and water (in liters) in the must before fermentation. Hydromodule for beer – the ratio of the mass of grain to the volume of water during mashing. In both cases, this indicator is expressed in two figures, the first indicates the proportion of sugar (malt, grain) in proportion, and the second indicates the equivalent ratio of water. The most common hydronic ratios are 1:3, 1:4 and 1:5.

When calculating the hydraulic module, it is important to remember:

- from 1 kg of sugar and maltose (saccharified grain mash) 0,61 l of alcohol is obtained, and from 1 kg of glucose and fructose (fruit and berry mash) – 0,647 l of alcohol;

- in an aqueous solution, sugar occupies 0,6 liters of volume, for example, when mixing 4 liters of water and 1 kg of sugar, the total volume of the solution will be 4,6 liters;

- for most yeast strains to work, the maximum concentration of sugar in the mash before fermentation should not exceed 20%, with the exception of some types of alcoholic yeast that can process 30% or more sugar;

- with a strength of mash above 10-12% vol. fermentation significantly slows down or stops completely, and after 14% vol. guaranteed to stop, with the exception of some alcoholic yeasts.

Optimal hydromodule for sugar mash

The simplest calculation option, since there are only 2 substances in the solution: sugar and water. In practice, moonshiners use three options for the hydromodule.

1:3 (for 1 kg of sugar 3 liters of water)

With this ratio, the concentration of sugar in the mash will be the maximum possible for most yeast – 20% (0,6 liters of sugar in volume / 3 liters of water * 100 = 20). The predicted maximum strength of the mash is 12,2% vol. (20 * 0,61 = 12,2).

Advantages:

- a small fermentation tank is required;

- during distillation, less energy is spent on heating the mash and time for the whole process.

Disadvantages:

- long fermentation time (often 3-5 days longer than with other ratios);

- when working with the limit values of sugar content and strength, the mash may stop fermenting at any time and it will need to be restarted, or some of the sugar will not be processed into alcohol;

- prolonged fermentation increases the amount of harmful impurities in the mash.

A water ratio of 1:3 can be recommended for some strains of alcohol yeast that are resistant to high sugar concentrations and strength (more than 12% vol.).

1:4 (for 1 kg of sugar 4 parts of water)

With this ratio, the sugar content of the mash is 15% (0,6 / 4 * 100 = 15), and the predicted strength is 9,15% (15 * 0,61 = 9,15). These sugar and alcohol values are able to withstand all strains of dry and pressed baker’s yeast, which are used by most moonshiners.

Advantages:

- the risk of a sudden stop of fermentation is minimal (at the right temperature);

- fermentation lasts a relatively short time, so the amount of harmful impurities is small;

- a fermentation tank of medium volume is required, the energy and time costs of distillation justify themselves.

It is the hydromodule 1:4 that is optimal for sugar mash.

1:5 (for 1 kg of sugar 5 liters of water)

The largest hydraulic module practically used by moonshiners. The sugar content of the wort is 12% (0,6 / 5 * 100 = 12), the estimated strength of the mash is 7.3% vol. (12 * 0,61 = 7,32).

Advantages:

- fast fermentation;

- smaller amount of harmful impurities in comparison with other values of the hydromodulus.

Disadvantages:

- fermentation requires a large capacity;

- the expenditure of time and energy for the distillation of mash is significant.

Hydromodule for grain mash (malt and enzymes)

The grain contains not only sugar (maltose), but also other substances: proteins, fats, etc., which are not involved in fermentation, therefore, for the optimal sugar content of the mash, less water is required than in the case of pure sugar. However, it must be taken into account that part of the water will evaporate during boiling (hot saccharification) of the wort.

For grain mash prepared by the classical saccharification method, a hydromodule of 1:3 (optimal) or 1:4 (if the raw material absorbs a lot of liquid, for example, rice) is used – 1-3 liters of water are taken per 4 kg of grain. For saccharification by the cold method (enzymes), the ratio of grain and water may be different and are indicated in the instructions for the enzymes. For example, for most Koji yeast, the recommended water ratio is 1:3.

Hydromodule for fruit and berry brews

Due to the significant variation in sugar content and density of raw materials, fruit and berry mashes are difficult to theoretically calculate. Due to the high juiciness, water is usually not added at all or is added in a small amount – 1: 0,25 (1 ml of water per 250 kg of expected fructose in the raw material).

The most correct solution is to measure the sugar content of the must with a hydrometer, then, if necessary, dilute it with water to a sugar content of 13-15%, which even “wild” wine yeast can withstand.

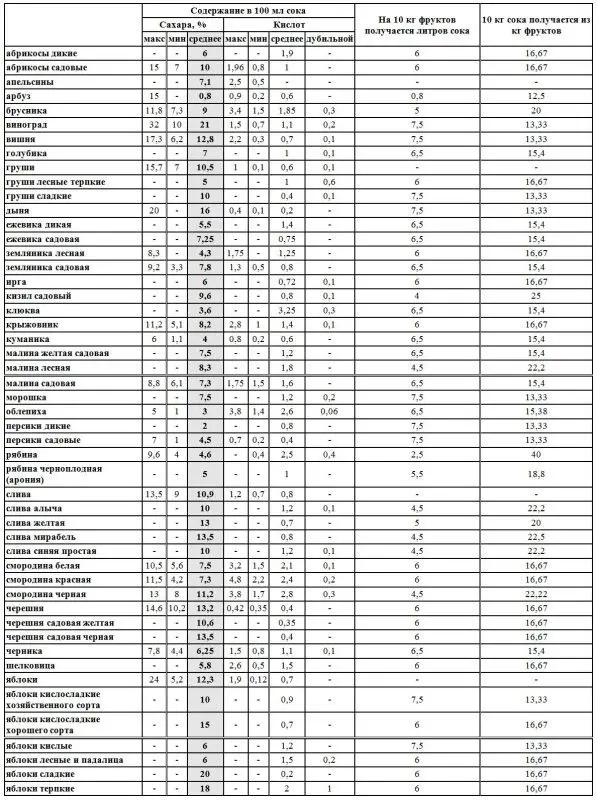

If there is no hydrometer, you need to know approximately the sugar content in fruits (berries) or their juice. This can be done according to the tables, it is advisable to take into account the variety and your region.

When the sugar content is below 14-15%, it is not required to dilute the wort with water. If sugar or fructose is added to fruit mash to increase yield, then 4 liters of water should be added for each kilogram added.

Hydraulic module for beer

If the beer is prepared according to an exact recipe, then it is pointless to think about the hydromodule, since the exact amount of all ingredients has already been determined, and the value of the hydromodule does not directly affect the characteristics of the finished beer.

It is necessary to take into account the hydraulic modulus only in the case of experiments. In brewing, the working range is 2,6-4 (1-2,6 liters of water per 4 kg of grain), but sometimes the authors of recipes go beyond it.

The less water, the higher the initial gravity of the beer, but a thick mash is prone to sticking and is poorly filtered, increasing the load on the pump. Also, a too dilute or thick mash (out of range) is less likely to be saccharified. The large water module reduces the amount of wash water allowed, as a result, some of the sugar will remain in the spent grains.