Contents

Good afternoon, dear readers! Would you like to be more productive, more productive, and less tired? The 5s system will help you with this. This system is actively used both in production processes, achieving high labor productivity, and for personal purposes.

What it is?

5s is a workplace organization system — «lean manufacturing» or a system for improving the production process. The main goal of creating such a system in production is the optimal reduction of losses, an increase in productivity. It is supposed to use all sorts of visual cues to obtain optimal labor results.

This system is used in combination with other methods to improve production efficiency. Only with the right selection and intensity of use can we hope to achieve our goals as soon as possible.

As a rule, the 5s system is used as one of the first lean methods before the introduction of other technological and other processes to improve the efficiency of production as a whole.

The essence of the 5s system

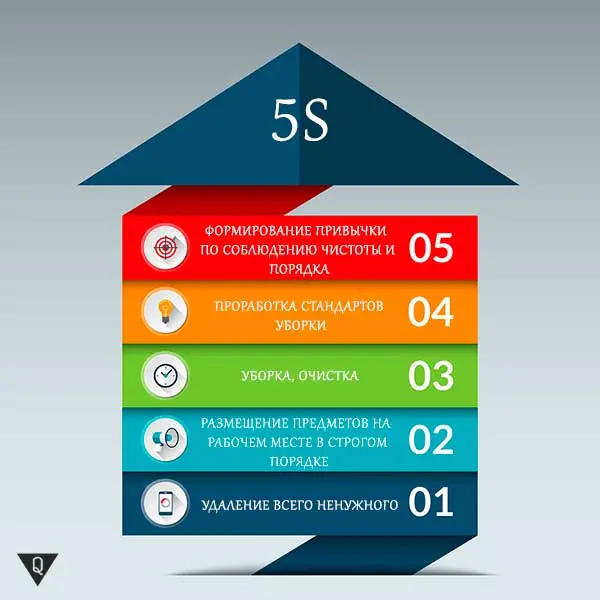

The system consists of 5 stages:

- Removing everything unnecessary. All items that are located within the working area are divided according to the principle: necessary, unnecessary and not needed soon. Unnecessary ones are to be deleted. The essentials stay where they are. But those that will soon not be useful for work are stored in centralized premises or removed at a certain distance from the workplace. At this stage, each employee is assigned a zone of his own responsibility.

- Placing items in the workplace in a strict order. As part of the implementation of this paragraph, quick and easy access to the necessary things should be ensured, as well as freedom of movement and appearance consistent with the company’s image.

- Cleaning, cleaning. The very first step is to determine the main source of contamination of the workspace. A list of persons with access to documents or devices is compiled, their actions are analyzed. Measures are taken to reduce the degree of contamination and maintain the working area in good condition.

- Development of cleaning standards. The people who have access to the work area are determined. Instructions for the use and care of devices, parts, documents are drawn up.

- Developing habits of cleanliness and order. The instructions that were drawn up and worked out at the previous stage are subject to approval by the company’s management (manager or director). An order is issued for the enterprise with a mandatory condition for its observance by all members of the team. Persons who, by virtue of the performance of their duties, have access to parts, instruments, documents are instructed. After its completion, a document is signed without fail, which is a confirmation of the successful completion of the briefing by certain persons. A person is appointed who will be responsible for storing devices, elements, parts, documents. In some companies, in parallel with these works, a system of fines is also drawn up for various violations that may occur in a particular area of activity.

Advantages of implementation

As part of the implementation of this system, an inventory of devices, tools, parts and other equipment is also carried out. A list of equipment and tools used is compiled. As an example, the company receives the first benefit and savings already at this stage. After all, it often turns out that many parts have not been used for a long time, and they can be handed over for recycling or for scrap. Production costs are very often reduced, and the volume of products created remains at the same level.

In addition to the financial benefits of implementing the 5s system, we also observe a psychological one. As a rule, employees begin to be proud of their workplace, work with great enthusiasm and dedication, as they feel their own contribution. It is pleasant for them to be in a clean and tidy workplace, which they themselves have made so.

By the way, I recommend taking a test to determine the psychological climate in the team.

Benefits for the enterprise from the implementation of the 5s system

All steps to implement the system in one way or another have a positive effect on certain aspects of the company’s activities. The most notable benefits are:

- standardization and visualization of production control methods;

- reduction of marriage and losses due to the failure of contaminated or neglected inventory;

- reducing the number of instrument failures and accidents due to equipment malfunction;

- minimizing occupational injuries, as the work area and inventory are located with optimal efficiency, are kept in order and clean;

- optimization of the sanitary and epidemiological state of the premises used;

- an increase in labor efficiency, and, as a result, an increase in economic benefits.

This system is the very first step towards financial growth and an increase in the productivity of the enterprise at the same cost. Together with other methods, this system gives an impetus and a great start, after which each subsequent innovation is considered by the enterprise team as a logical continuation of the previous stage.

With significantly low costs for its implementation, it is possible to:

- find unused premises and zones that are subject to redistribution as part of production needs;

- optimize the workspace by placing only effective elements there;

- improve the hierarchy in the enterprise, reassign departments or people to accelerate economic growth;

- optimize the consumption of elements and materials due to their accounting and careful use;

- increase the productivity of the staff due to a sense of self-importance in decision-making, even as part of the arrangement of their working area.

It is understood that each employee, from the manager to the janitor, is significant, as he makes proposals for changing his workspace and common industrial premises. In this way, the feeling of significance increases and, as a result, self-giving too. And this is the main guarantee of the efficiency of any production.

Conclusion

As you can see, it is not necessary to invest huge amounts of money in production in order to increase its economic efficiency. It is enough to start with the 5s system — and you will immediately notice the first results.

If we talk about our own performance, the recipe is the same. Organize your workplace according to this system, put the details in order and keep it constantly clean. You will see how much more you can do, get less tired and feel better after achieving your goals. Read more about personal productivity here.

With the introduction of such a system, you will think less about how to make yourself work.

Good luck to you and see you for a new interesting conversation!