Contents

A monolithic strip foundation is a one-piece structure made of steel reinforcement and a concrete strip. It is located along the perimeter of the building and under all load-bearing walls and elements. If the technology is followed, the structure becomes a single whole – a monolith – and has a very high reliability and strength characteristics. For this reason, it is popular both in the construction of multi-storey buildings and private cottages.

It is advisable to use a monolithic strip foundation at a low level of groundwater: when they are located below the required depth of the foundation. Otherwise, it is necessary to organize drainage, and these are additional (and considerable) funds.

Device and types

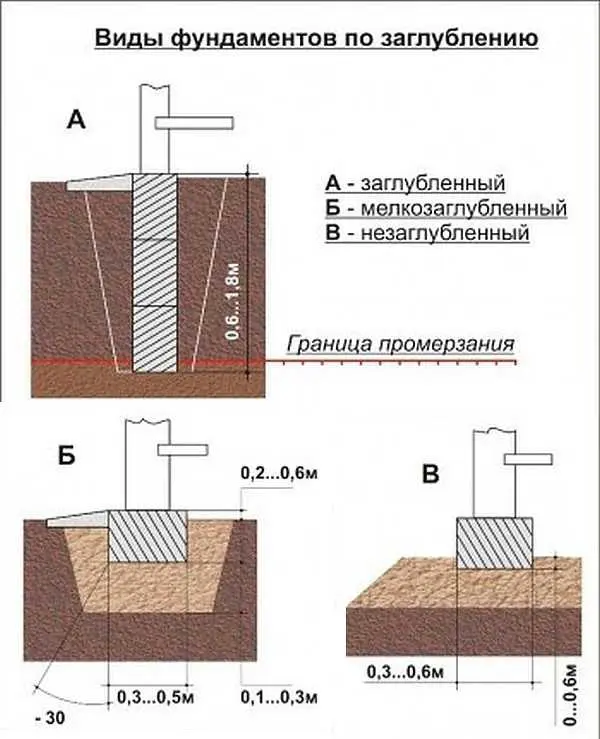

According to the depth of occurrence, strip foundations are shallow and deep occurrence. Shallow ones can be used on calm, non-fluffy soils with good bearing capacity for buildings of small mass – made of wood and erected using frame technology.

In this case, the tape should go 10-15 cm into the hard layer, which is located under the fertile one. At the same time, according to the standards, it cannot be less than 60 cm.

Deep monolithic strip foundations are made for heavy, massive houses. In the general case, they are lowered 10-15 cm below the level of soil freezing for a given region. In this case, the sole must rest on a layer with good bearing capacity. If this is not the case, you have to go deeper. For example, if the level of soil freezing is 1,2 m, and the fertile layer ends at 1,4 m, then you have to fall below 1,4 m.

With or without formwork

In general, the technology for erecting a monolithic strip foundation provides for the installation of formwork. These are structures made of shields that give shape to concrete and prevent it from spreading. It is clear that the formwork is an additional cost for materials, as well as additional time for its assembly and installation.

Sometimes, in order to save money, on good soils, a foundation pit is dug exactly according to the markup – to the desired width and depth. And concrete is poured into these pits without formwork. Such a technology cannot guarantee the required degree of reliability, and it is impossible to predict the result. The fact is that concrete needs a certain amount of water to gain normal strength. Without formwork, water, although a little, is absorbed into the ground, which can affect the quality of the concrete stone itself. In the worst case, it may crumble.

They get out of the situation by spreading a plastic film in the trench. But then they walk along it – reinforcement needs to be done. Both rods and boots damage the film more than once. As a result, moisture still leaves.

In some cases, such foundations can stand for a certain number of years without problems. But sooner or later, cracks appear or concrete begins to crumble. The second difficulty in working with such a foundation is its far from ideal geometry. In order to reduce heat loss, the foundation is insulated, most often with foam boards or extruded polystyrene foam. Try sticking them on an uneven surface. The situation is the same with vapor barrier: the film is very difficult (almost impossible) to stick on uneven, porous concrete with soil inclusions. Whether or not this approach is justified is up to you, but such a foundation can only be recommended for a fence or a barn.

Basement in a house with a strip foundation

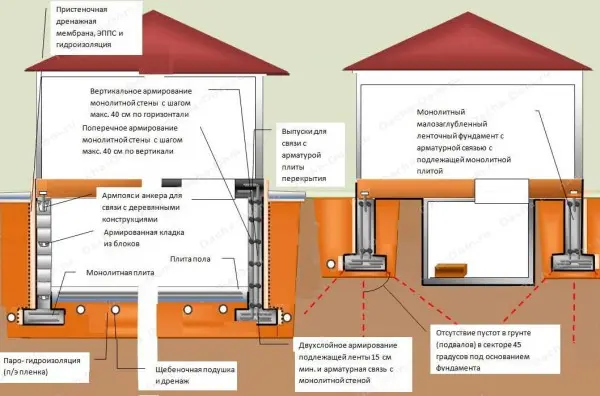

The basement can be the same area as the house, or it can occupy only part of the space. And you need to decide on its dimensions before the design stage.

If the basement occupies only a certain part of the space, it will be possible not to take out all the soil, but to dig only trenches under the tape. They also dig the basement according to certain rules. Its placement and arrangement can also be developed at the design stage.

If it was decided to make the basement later, then you need to choose a place and determine the depth so that when drawing lines from the base of the house at an angle of 45 °, they do not pass through the voids (shown in the photo on the right).

If the basement is located under the entire area of the house, then the entire soil is removed to the required depth. In general, such a project cannot be called a budget one: there is much more work and expenses. Firstly, reinforced reinforcement of the walls and their greater thickness are required. Since there will be no soil inside, the walls of the basement will need to resist the pressure of the soil from the outside. Therefore, the thickness of the tape will be much larger and the reinforcement is needed more powerful, it is laid with a smaller step, and the number of reinforcement belts will also increase. As a result, only the consumption of reinforcement for the foundation will increase. Secondly, concreting and, possibly, reinforcement of the basement floor over the entire area will be required. And these are again materials – concrete and reinforcement. Thirdly, effective ventilation will be needed to remove underground gases. Such a structure can no longer be designed independently. The job must be done by a professional with extensive experience.

Monolithic strip foundation: construction stages

Even if an organization or a team will build a house, the developer needs to know the technology: this is the only way to control the process and be sure of the quality of the work.

In general, the technology is as follows:

- Site marking.

- Land works.

- Consolidation of the base, basic bedding and tamping.

- Ribbon layout.

- Waterproofing.

- Assembly and installation of formwork.

- The binding of reinforcement.

- Concrete pouring and vibrating.

- Curing.

Some explanation is required. Double marking – a plot and a tape – is needed if the house will have a basement under the entire area of uXNUMXbuXNUMXbthe house. The first time you mark out the area of uXNUMXbuXNUMXbthe house, taking into account allowances for the installation of formwork. There is no way to do without it. Then, after the pit is dug and the bottom is poured and rammed, it will be necessary to mark the tape. According to these marks, formwork will then be installed, which will form the “profile” of your house.

Now a little more about each of the stages.

Plot marking

Since for the design the soil was examined in a certain area, it is necessary to bind rigidly. The underground structure is often heterogeneous and a shift of half a meter can be critical: suddenly there are subsidence rocks or a cavity. It is hardly worth positioning with an accuracy of up to a centimeter, but it is advisable not to miss much.

earthworks

Their volumes and the equipment used depend on whether you have a house with or without a basement. If not, then you marked the tape – and you will need to remove the soil. Only with a margin for the installation of formwork – and this is sometimes 50 * 80 cm on each side. Shields need spacers to keep them from falling apart.

If the house has a basement, all the soil will need to be removed. The dimensions of the pit are 2-5 m larger than the dimensions of the foundation. This is all the same stock for formwork spacers.

For large volumes, it is better to use special equipment. Renting it costs a lot, but the work of a brigade of “diggers” for several days will not be cheaper. The speeds are incommensurate.

The upper fertile layer is laid separately, it can be immediately distributed throughout the garden. The rest of the soil is piled up: partly it will go to backfilling, partly it will need to be taken out.

Sealing the bottom of the pit and backfilling

After the bulk of the soil has been removed, the bottom must be leveled and compacted. When working with an excavator, it often happens that some areas are 20-30 cm deeper than necessary. All these irregularities must be corrected: fall asleep and tamp.

Ramming and leveling are needed over the entire area of the pit or trench. And not with a deck. It can be used if you are building a fence. Even during the construction of a bath or cottage, it is better to use a vibrating plate.

Let’s see why. This level accounts for the entire load of the building. Even small voids and irregularities can cause uneven shrinkage and cracking. And the bottom after excavation of the earth is uneven. And you can eliminate this with a rammer. It is even better if a layer of sand with medium or fine grain is poured onto the bottom. Due to its smaller size, it aligns better. But for better and faster compaction, it needs to be moistened (pour water to wet its entire volume). The vibrating plate creates a force that compacts the sand by 15-20 cm. It is this layer that needs to be poured at a time. If according to the project, a layer of sand is 30 cm, then it is first necessary to pour 15 cm, shed and compact it to a high density. Then pour the second one and spill and tamp it too.

Often the project requires the creation of sand and gravel bedding. Then another layer of crushed stone with a fraction of 30-60 mm is poured over the compacted sand. And he, too, rambles. The thickness of this layer of backfill is 10-15 cm. It also needs to be poured in small layers of about 5 cm each and compacted.

In this case, the soil is not only leveled, it also becomes more dense: crushed stone is driven into the underlying rock, increasing its bearing capacity. Since the plate hits the pebble with great force, the compaction occurs to a depth of 40-50 cm. And this is very good.

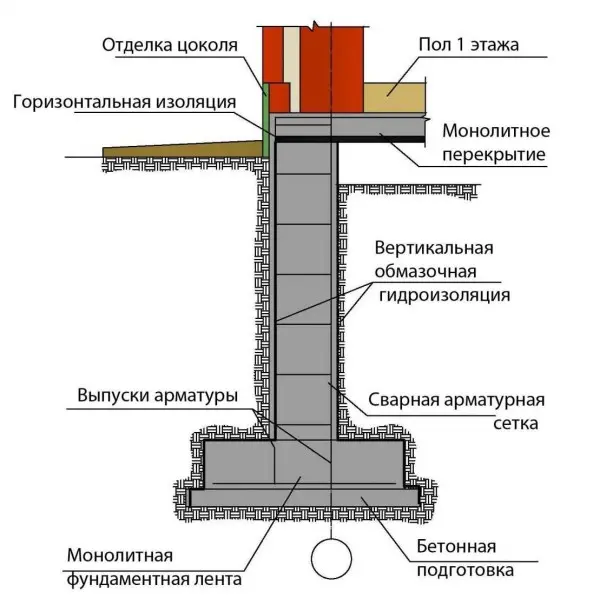

Formwork for a monolithic strip foundation

The formwork is made of boards with a thickness of at least 40 mm, low-grade plywood or OSB. Plywood is inexpensive, special – formwork. It has a lamination on one side – there is a protective film. Therefore, it can be used several times.

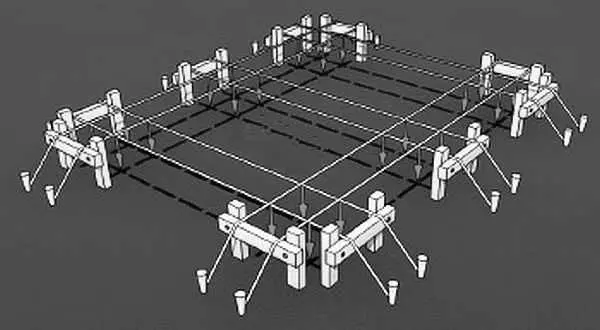

Shields made of sheet materials are reinforced with transverse and longitudinal bars. From the boards are fastened with crossbars. The assembled shields are exposed according to the marking of the tape, fixed on the outside with slopes, and spacers are installed inside. All these fasteners must give the formwork the specified dimensions. They will not allow the shields to fall apart or bulge when pouring concrete: the mass will put considerable pressure on the walls, therefore the fasteners must be reliable.

Reinforcement

Due to the structural features – large length and small width – the strip foundation is mainly affected by forces that try to break the strip across. Therefore, it must be strengthened along the long side. Here they use powerful ribbed reinforcement from 10 mm in diameter and more. All transverse reinforcement only stabilizes the longitudinal bars in space, therefore it can be taken smooth and used with a small thickness – 6-8 mm.

Moreover, in most cases, regardless of the depth, two reinforcing belts are sufficient: at the top and bottom of the tape. The exception is the foundation device with a basement under the whole house.

The reinforcement scheme of the tape monolithic foundation is shown in the photo. At each connection point, the reinforcement is tied with a special wire. This is done manually using hooks or automatic devices – knitting guns.

There is another way: welding. But its use is not always justified. The work goes faster, but the connection is tough. When knitting with wire, the reinforcement has some freedom. And it helps to compensate for some deformations without destroying the concrete. When welding, the joints are rigid, which on the one hand is not bad, but on the other hand, a too rigid structure can cause cracks.

Another point: the welding site always begins to collapse first. Although the reinforcement is located in the thickness of the concrete, and therefore does not corrode (oxygen does not penetrate to it), but in case of any violations and the supply of oxygen, the welded joints are destroyed first.

At this stage, ventilation products and ducts are laid, through which engineering communications will be brought to the house. If you forget about it, you will have to destroy the monolith, and this is very undesirable: the fewer flaws, the stronger the structure will be.

Filling the strip foundation

When building a more or less large house, it is easier and better to order the delivery of ready-made concrete to the site in a mixer. Then the filling can be done in one day.

You can make your own concrete. But this requires a concrete mixer. Manually, mixing the components in troughs, it is impossible to ensure the proper degree of uniformity.

For manual pouring, at least three people will be needed: one kneads the concrete in a concrete mixer, the second distributes the finished portion, and the third vibrates the newly poured area.

Vibration of concrete is carried out using manual or portable submersible vibrators. This process allows you to remove all voids, more evenly distribute the aggregate. As a result, the strength characteristics of concrete are much improved, it acquires frost resistance due to the fact that it absorbs water much less. Therefore, do not skip this stage: with the same components in the solution, we get a higher grade concrete as a result.

Another point: when pouring from a machine, you need to use special gutters. Firstly, it is easier for them to deliver concrete to the desired point, and secondly, the solution should not fall from a great height. If the fall height exceeds 150 cm, it delaminates. The result is low strength.

Curing

If the work was carried out in hot, dry weather, the tape must be covered with plastic wrap or any other material that prevents the rapid evaporation of moisture. Since the depth of the concrete is large, wetting the surface will not give tangible results. The main thing is not to let the top dry out and the film copes with this task perfectly.

If the temperature during and after pouring is kept around +20°C, three days after pouring, the concrete will gain a strength of about 50%. And on the fourth day, the formwork can be removed and proceed to further work.

At lower temperatures, you need to wait longer: at +10°C it is already 10-14 days, and at +5°C the setting process practically stops. In such conditions, it is necessary either to insulate the formwork or to heat the concrete.

The monolithic strip foundation is ready, but there is still work to be done on its insulation and waterproofing. Only after that it is covered (backfill).