Removing snow with a conventional shovel is difficult and time consuming. Such a tool can be dispensed with in a small area. To clear large areas, mechanized snowplows are used. For example, if you use a shovel with an auger for snow removal, then the work can be done several times faster and with less labor.

Varieties of screw shovels

Despite the wide variety of auger shovels, these tools have a mechanism similar in design and principle of operation – an auger. It is he who is responsible for capturing, grinding and ejecting snow. If we consider this snow removal tool in general, then an auger shovel for snow removal is:

- The single-stage model has only one auger with spirally wound circular knives as a working mechanism. During the rotation of the drum, the blades capture the snow, grind it and feed it to the blades, which push the snow mass through the discharge sleeve.

- The two-stage model has a similar device, only before the ejection, the snow passes through the rotary mechanism. The rotating impeller additionally loosens the mass with its blades and pushes it out through the outlet sleeve with the air flow.

According to the type of drive, the screw shovel is:

- In terms of functionality, a hand tool resembles a scraper blade, only the snow inside its body is ground with an auger. The drive here is the physical strength of the operator. A person simply pushes a shovel in front of him.

- The mechanical tool is powered by a motor. Moreover, it can be electric or internal combustion engine. A mechanical shovel may not be equipped with an engine, but serve as a hitch for a walk-behind tractor or a mini-tractor. In this case, the auger drive is connected to the traction unit motor. The range of snow ejection in a mechanical shovel can reach 15 m. A hand tool does not have such parameters. He just pushes the snow aside. Mechanical auger shovels differ in the type of movement:

- A non-self-propelled tool usually has skis instead of wheels. It moves from the pushing efforts of a person. The motor is responsible only for the rotation of the auger.

- A self-propelled tool is on wheels and caterpillars. Such machines move by themselves, and the person only controls the handle.

Despite significant differences in design, the principle of operation of any auger shovel is the same.

When the snow plow starts moving, regardless of the type of drive, the rotating auger captures the snow and then throws it to the side through the sleeve. The ejection distance depends on the speed of the working mechanism. The operator regulates the direction of ejection with a rotary visor.

Screw miracle shovel FORTE QI-JY-50

An ordinary shovel can clear a small area of snow, but still this process is laborious. The mass captured by the bucket must be lifted in front of you in order to be thrown to the side. A lot of the load from such work goes on the arms and back. The developed manual miracle shovel is a mechanical snow removal tool. A feature of its design is the auger installed inside the dump bucket.

Model FORTE QI-JY-50 is a worthy representative of this instrument. The blade itself is made of durable plastic. Capture width – 60 cm. An auger is attached to the blade. It begins to rotate when a person pushes a shovel in front of him. At this time, the spiral-shaped blades capture the snow and throw it to the side. Thanks to the auger, a person puts less effort into pushing the shovel. This reduces the load on the spine.

It is conditionally possible to distinguish two types of snow cover that a miracle shovel can handle:

- It is frosty outside, and fluffy snow up to 15 cm thick covered the ground. There is no better weather for working with hand tools. The shovel will easily ride on the surface of the earth, and the auger will capture the entire thickness of the cover. During operation, you need to find the correct angle of inclination of the tool relative to the ground. The auger must not touch the ground, otherwise it will slow down.

- The snow cover was packed, and during the night it grew up to 30 cm. A miracle shovel cannot cope with such a layer. The auger will simply get stuck in the snow and will not rotate. Only a strong person can physically move such a thickness. Older people or teenagers will not master this work.

However, there is a way out of the last situation. The craftsmen have learned how to upgrade the FORTE QI-JY-50 shovel. To do this, an additional blade is attached in front of the auger at a height of 15 cm. When a person starts to push such a combination tool, the front scraper scrapes off the top layer of snow. The next miracle shovel easily captures the remaining cover 15 cm thick.

DIY mechanical auger shovel

Factory snow blowers are quite expensive, so many craftsmen make mechanical shovels themselves. The motor can be used electric, but there are inconveniences of attachment to the outlet. In addition, the cable is constantly tangled underfoot. It is optimal to find an air-cooled gasoline engine. A motor from a walk-behind tractor is perfect.

The manufacture of a mechanical shovel is performed in the following sequence:

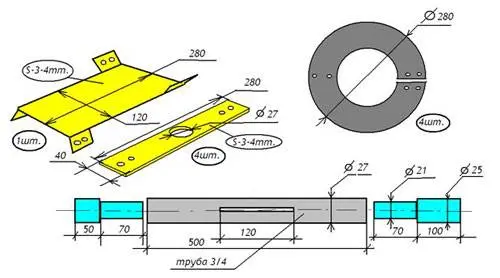

- For the auger, you need to find a shaft. An ordinary metal pipe 20 mm thick will do. Pins are welded along the edges, on which closed-type bearings No. 305 are mounted. Immediately you need to decide on the type of drive. If it is a belt drive, then a pulley is mounted on one of the pins. For chain transmission, an asterisk from a moped or bicycle is used. Two steel plates measuring 12×27 cm are welded in the center of the pipe. They will play the role of shoulder blades. Circular knives can be cut from a conveyor belt or car tire. You will need four rings with a diameter of 28 cm. They are attached to the shaft with turns towards the blades.

Good circular knives are made from steel. If you cut a jagged edge on them, the auger will easily take snow with an icy crust.

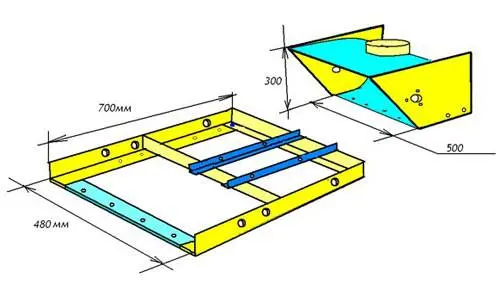

- The frame of a mechanical shovel is welded from the corners. You can use a bolted connection. Jumpers are provided on the frame, which will serve as a mount for the engine.

- The bucket is curved from a sheet of steel 50 cm wide. Since the diameter of the knives is 28 cm, the semicircular body inside should have a height of 30 cm. The side walls of thick plywood are fixed with rivets or bolts. The second option is better because of the ability to disassemble the bucket if necessary. Holes are cut out in the center of the side walls, and hubs for bearings are bolted here. A hole with a diameter of 160 mm is cut from the top of the bucket with a jigsaw. It should be located in the middle of the body directly above the shoulder blades. A galvanized pipe is attached to the hole. A sleeve will be put on it to eject snow.

- Before assembling all the components of a mechanical shovel, you need to complete the drive. If an asterisk is put on the auger shaft, then the motor PTO must be equipped with a similar part. The same is done in the case of using pulleys.

- The assembly of the shovel begins with the installation of the auger inside the bucket. To do this, the shaft with bearings is inserted into the hubs mounted on the side elements of the housing. The finished bucket with auger is bolted to the front of the frame. A galvanized or PVC pipe with a visor is put on the outlet pipe.

- The motor on the frame is positioned so that the alignment of the drive pulleys or sprockets is observed. The engine mounting elements must be adjusted on the frame by movement. This will allow you to achieve the optimal tension of the belt or chain.

- Chassis can be wheels or skis. The first option is reasonable to use for a self-propelled machine. In this case, it will be required from the engine to make another drive to the wheelset. A non-self-propelled machine is easier to put on wooden skids. Skis will be easier to go through the snow and will not fail in a large snowdrift.

When all the components of the mechanical shovel are assembled, all that remains is to attach the control handle. It is made from a pipe 15–20 mm thick. The form is given to any convenient for the operator. Usually it resembles the letter “P” or “T”.

The video shows a homemade snowplow:

Starting the engine of a mechanical shovel is performed after checking all the nodes. The auger should rotate freely by hand inside the bucket, and the knives should not catch on its walls. After the test, it is desirable to close the drive units with a casing for your own safety.

The speed of snow removal with an auger shovel is high. For a person, such work will become more useful outdoor entertainment than a tedious task.