Contents

Reviews of cow milking machines help cattle owners and farmers to choose the best models from the equipment on the market. All units are arranged and work on almost the same principle. Design features are inherent in each model, and it is this nuance that is taken into account when choosing.

What are milking machines

To understand how different types of milking machines for cows differ, you need to know the main device.

Any milking machine has:

- Glasses consisting of a body and an elastic insert. The milking element is put on each udder teat.

- Hoses made of non-toxic polymer for transporting milk, air injection.

- Cans are usually used from aluminum or stainless steel. In household devices, containers can hold from 19 to 25 liters of milk.

- The pulsator, pump and collector are the main mechanisms of the apparatus. The nodes create a pulsating air pressure, due to which milking is carried out.

Initially, all milking machines worked on a two-stroke system. Milking was carried out by compressing the nipples with pulsating vibrations of the elastic inserts of the cups. For cows, this method of pumping milk is not very comfortable. Modern equipment works on a three-stroke system. The elastic insert of the teat cup compresses, unclenches the nipple, and maintains a rest pause between actions. For an animal, the process resembles manual milking or natural udder sucking by a calf.

According to the method of milking cows, the machines are divided into two types:

- suction;

- clutch release.

The first type of milking machines, due to the operation of a vacuum pump, sucks milk. Pressure is created inside the elastic inserts of the cups. The milk starts to flow. When air in the system is replaced by vacuum, the pressure difference compresses the cup inserts. The nipples shrink, the milk stops flowing.

Squeeze-action milking machines produce milk by mechanical compression of the cow’s teats. The equipment creates high pressure and vacuum in its system. The units are noisy, but the cows adapt over time.

Milking machines express milk simultaneously from all teats of a cow or alternately in pairs. The type of milking is chosen according to the age of the animal. For an old cow, the continuous method is suitable. Two- or three-stroke milking is acceptable for a young animal.

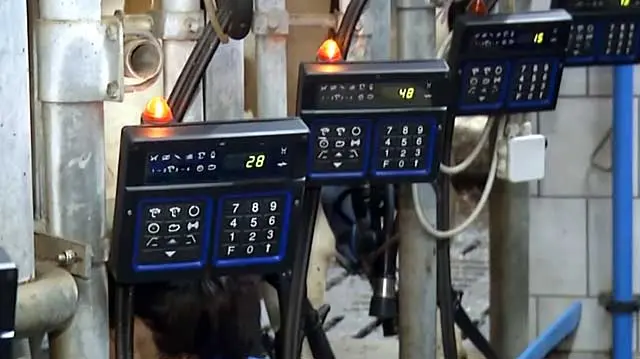

Industrial and domestic units differ in performance. For private use, milking equipment is usually mobile, small in size and easy to operate. Industrial installations often require connection to stationary milk collection tanks. The equipment is equipped with an automatic control that allows you to choose an individual mode for each cow.

The classification of milking machines differs by the type of engine used:

- Dry type motors are environmentally friendly, easy to operate and maintain. The downside is the weak resistance to moisture. During storage, it is important to prevent moisture from penetrating inside the engine. Dry motors are noisy, tend to overheat with increasing load.

- Oil motors are quiet. The unit does not bother cows, it is resistant to high loads. The disadvantage is the complexity of maintenance. The oil level must be constantly maintained in the engine. In the cold, it is able to solidify, and after the wear of the working units, it can flow out of the body. The engine starts hard to start, the milking equipment becomes clogged with oil.

The vacuum pump is responsible for the process of milking the cow. By design and operation, the node is of three types:

- Diaphragm pumps are usually installed on budget devices for private use or a small farm. These milking machines are designed to milk a maximum of 3 cows.

- Piston type pumps are characterized by increased power. The node is often installed on industrial machines. The pump has impressive dimensions, works with great noise, is prone to overheating.

- Dry and oil type rotary pumps are considered universal and are most often found on modern milking installations. The equipment works quietly, does not disturb the animals.

All types of milking machines are designed to work in certain conditions. This nuance must be taken into account when making a choice.

The video shows the farm:

Which type of milking machine is better – dry or oil

An experienced farmer purposefully chooses a milking machine for his cows. To understand for an inexperienced person between a dry and an oil apparatus, one must know the features of their device and operation.

Dry vacuum pumps have graphite vanes. They are slightly subject to wear, they are cheap, but they are afraid of dampness. Additionally, the following points can be distinguished from the advantages:

- easy maintenance;

- environmental friendliness due to the absence of oil emission;

- light weight;

- easy start-up of the pump regardless of temperature conditions;

- no risk of oil contamination of milk.

The main disadvantage is considered noisy work. In cows of shy breeds, milk yield decreases, animals behave aggressively.

Oil pumps work stably as long as the oil level is maintained in the system, there is no leakage. The equipment has undeniable four advantages:

- quiet work;

- resistance to overheating from the load;

- simultaneous milking of several cows;

- long service life due to less wear of rubbing parts that are constantly in oil.

However, oil pumps have many disadvantages:

- it is difficult, and sometimes impossible, to start in severe frosts;

- the oil level must be constantly monitored, periodic topping up, which leads to unnecessary costs;

- in the event of an oil release, the surrounding area, equipment, and milk are contaminated.

It is very difficult to determine by the advantages and disadvantages which of the pumps is better. The choice of model depends on the expected conditions of use. Each milking machine is no worse and no better, but is designed to perform its task.

When choosing between an oil and dry pump, they are guided by the following indicators:

- Service staff. It is easier for one milkmaid to transport a mobile dry apparatus. For a complex team, an installation with an oil pump is suitable.

- The number of cows. For a small number of livestock, a dry-type installation is suitable, but it will not cope on a large farm. If there are more than 20 cows, then only equipment with an oil pump will provide quick milking.

- Service availability. If a person is poorly versed with technology, there is no free time, preference is given in favor of a dry milking machine.

- Life time. Oil reduces wear of rubbing parts, reduces the likelihood of overheating of the pump from loads. Equipment will last much longer than dry-type counterparts, even if stored in high humidity conditions.

- Breeds of cows. Animals are characterized by shyness, which affects the reduction in milk yield. If the cows are afraid of noise, it is better to refuse the installation of a dry type.

After an accurate analysis of all the nuances, it will be possible to correctly determine the choice of model.

The video compares different types of milking machines:

How to choose a milking machine

To make the right choice of milking machine, it is necessary to clearly define three questions:

- financial opportunities;

- features of the breed of cows;

- farm needs.

For a small number of cows, the simplest two-stroke milking machines are chosen. Three-stroke milking machines are expensive. The equipment is used on large farms. Milking of cows can be carried out on pasture or in a barn. If the first option is not ruled out, equipment mobility is preferred. The main criterion for choosing a model is the type of pump.

Rating of milking machines for cows

Each farmer has his own opinion about which are the best milking machines, and which ones it is desirable to refuse. A novice breeder can be guided by tips, reviews and ratings of models:

- The Italian equipment of “Milkline” was appreciated from the best side by the farmer, who prefers European quality. Silent operation allows you to milk a cow in the presence of a calf. Depending on the model, the machine is able to serve from 1 to 35 cows.

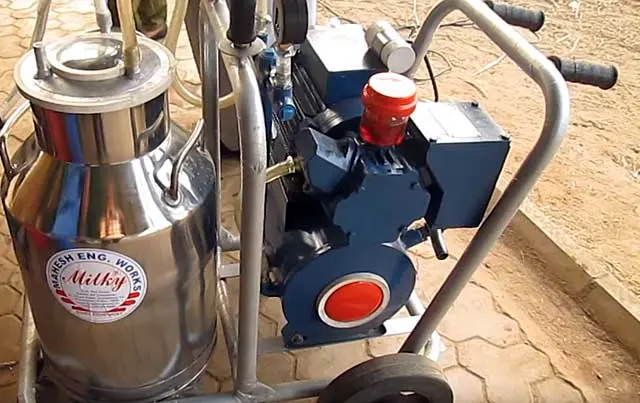

- The Delaval milking machine shown in the photo is equipped with a two-level vacuum pump. The presence of cow milking control electronics, data transmission to the control panel gives the right to equate the equipment to a professional type. The unit is equipped with a milk sampling unit, has the ability to connect to the pipeline of a stationary system. The milking machine is intended for a farm with a large number of cows.

- The domestic brand “Uda” is represented by models 8a, 16a, 32, Herringbone and Tandem. The main difference is power, the ability to serve a certain number of cows. The milking machine, depending on the model, can serve from 100 to 350 heads. At the factory, the unit is connected by a milk line to a stationary milk receiver.

- For a private courtyard, the Veles apparatus is considered an excellent choice. The equipment is used for one cow. Alternately, you can serve up to 8 heads. Milking time for 1 cow is about 10 minutes. The silent process does not scare the calf.

- The domestic equipment manufacturer Doyushka produces milking machines for cows, goats, horses and even sheep. In private use, models 1P and 1C are popular. On large farms, powerful milking machines are used, designed to milk at least 10 cows per hour.

- The mobile device “Burenka” is similarly produced by a domestic manufacturer. The equipment is easy to transport on wheels even across the meadow to the place of milking. The connection is made to the outlet. The installation is able to serve up to 15 cows.

- The popular brand “Moya Milka” presented 10 varieties of milking equipment. Models differ in performance, complete with a can made of aluminum or stainless steel. Quiet milking, which does not frighten the calf, is considered a big plus.

- For farms with livestock from 50 to 400 cows, a professional complex “Molokoprovod” has been developed. The equipment carries out milking, filtration and pumping of milk, transportation to a stationary container of the plant. Primary collection is carried out in a tank with a volume of 50 liters.

The rating of milking equipment is based on feedback from farmers and ordinary cow owners. If other firms are not on the list, then they are no worse. Equipment must be selected on demand, and the rating is only an auxiliary tool.

Conclusion

Reviews about milking machines for cows are of a different nature. Some people are happy with the purchase, while others are upset. There are many reasons: inability to use, the wrong choice of model, or vice versa, it was lucky to get exactly the unit that facilitated the maintenance of cows.