A coil is an indispensable part of a moonshine still, designed to condense alcohol vapors by removing heat from water or air through the walls. Despite the complex definition, anyone can make a coil at home. A homemade version will work no worse than store-bought counterparts. We will consider the theory and practice of manufacturing.

Coil parameters:

1. Material. The most important factor affecting the safety and taste of moonshine. The material of the coil should not react with alcohol or be toxic, but at the same time have sufficient thermal conductivity to condense the alcohol vapor.

Given the requirements, you can make a coil of copper, aluminum or stainless steel. Glass is also a suitable material, however, it is easier to buy a ready-made glass coil in a chemical store than to make something similar yourself.

Copper has the best thermal conductivity, but many moonshiners consider it a toxic material, in fact it is not. For example, for several centuries the French have been distilling all strong alcohol in alambicas – special copper distillers, and so far no one has been poisoned. In second place in terms of thermal conductivity is aluminum (1.6 times worse than copper), but it is relatively cheap, accessible and easy to process. Stainless steel coils are 3-4 times inferior to copper coils, moreover, the exact brand of stainless steel is not always known, and only food grade ones are suitable for home brewing, which withstand high temperatures and do not react with alcohol.

2. Dimensions. The longer the tube, the larger the area of contact between vapors and water (better cooling), but at the same time, the hydraulic resistance increases (the speed of the distillation decreases). The correct length of the coil in the moonshine still (the tube itself before curling) is 1.5-2 meters.

The larger the cross section (inner diameter) of the tube, the larger the contact area and the lower the resistance. I recommend using a tube with an internal diameter of 8-12 mm.

The small wall thickness of the coil increases thermal conductivity, improving condensation, but too thin tubes are difficult to process and operate, because they are very fragile. In addition, when two media come into contact, in our case, condensed alcohol and steam, the thermal conductivity drops sharply, regardless of the size and material of the wall. The optimal thickness of the coil tube is 0.9-1.1 mm.

3. Orientation in space. The coil can be positioned vertically, horizontally or obliquely. In home brewing, it is desirable to use a vertical connection scheme, in which the condensed distillate flows by gravity and does not create additional obstacles to the movement of steam.

Vertical coils are ascending (steam goes from bottom to top) and descending (from top to bottom). For minimum resistance, steam must be supplied from above.

4. Cooling system. The coils are cooled with water, ice and air. The last two options are less efficient and require complex structures, so we will not consider them further. Water cooling systems are open – they work on running water, and closed – the tank is immediately filled with the right amount of water. The design of closed systems is simpler, but they cool worse, often the moonshine turns out to be warm at the output, and even hot after a couple of hours of distillation.

In open systems, water circulation cools the coil much better, moonshine turns cold. In addition, in flow structures, a smaller water tank is used, as a result of which the apparatus is more compact.

Correctly supply water from below, and output from above. For normal cooling, water must move towards moonshine, otherwise the lower part of the coil will not cool well. This scheme is called “countercurrent mode”.

Coil Manufacturing Technology

You will need a copper, aluminum, brass or stainless steel tube 1.5-2 meters long, with a cross section of 8-12 mm and a wall thickness of 0.9-1.1 mm. In advance, I advise you to find a housing (reservoir) for installing the coil. The diameter of the pipe winding depends on the size of the body. For example, a plastic sewer pipe with a diameter of 75-80 mm is suitable. For effective cooling, the coil must occupy at least 15-20% of the volume of the tank.

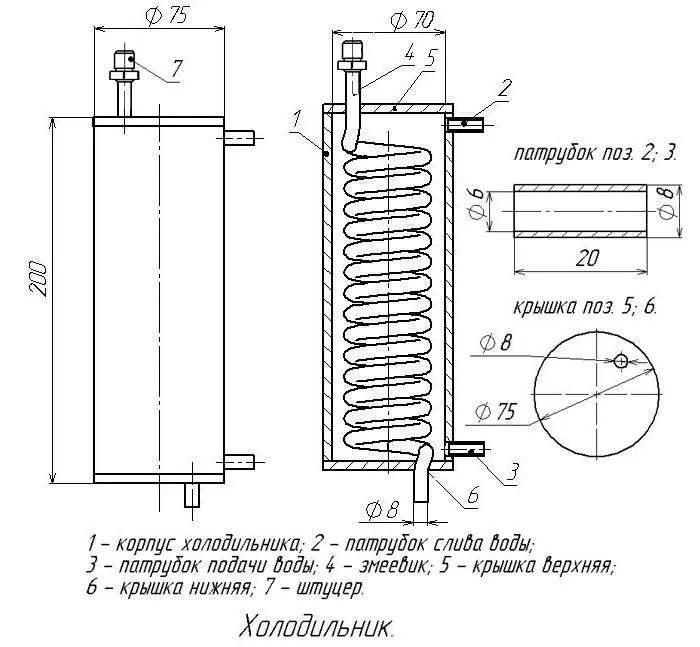

The coil installed in the body is called the refrigerator of the moonshine still, the drawing is shown in the photo.

Sequence:

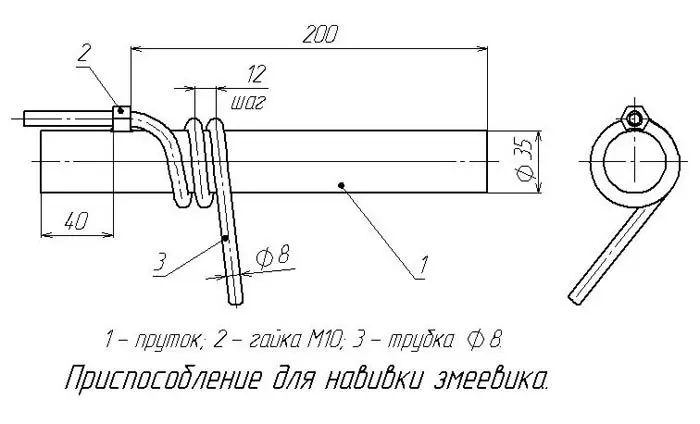

1. Stuff the tube tightly with dry bulk material, such as river sand or soda, so that the metal does not flatten when curled. In extreme cases, you can fill the tube with water and freeze.

2. Stuff wooden chopsticks (pegs) onto the ends of the tube. An alternative is to solder or clamp tightly. It is desirable to weld a nut on one end.

3. Wind the tube around any smooth object with an even circular section of the desired diameter (in the example 35 mm) with a step between turns of 12 mm.

4. Release the ends of the coil, pour out the sand, rinse with running water.

5. Install branch pipes for water inlet and outlet on the cooler body.

6. Place the coil in the housing, install plugs at the top and bottom, seal all connections with superglue or in another way.

With a heating power of 2.5-3 kW, the capacity of the refrigerator of the proposed design is 3-4 liters per hour.