Contents

The Dimroth refrigerator is one of the most common units in home brew and distillation columns. The main thing is to correctly make and correctly use this design.

Principle of operation

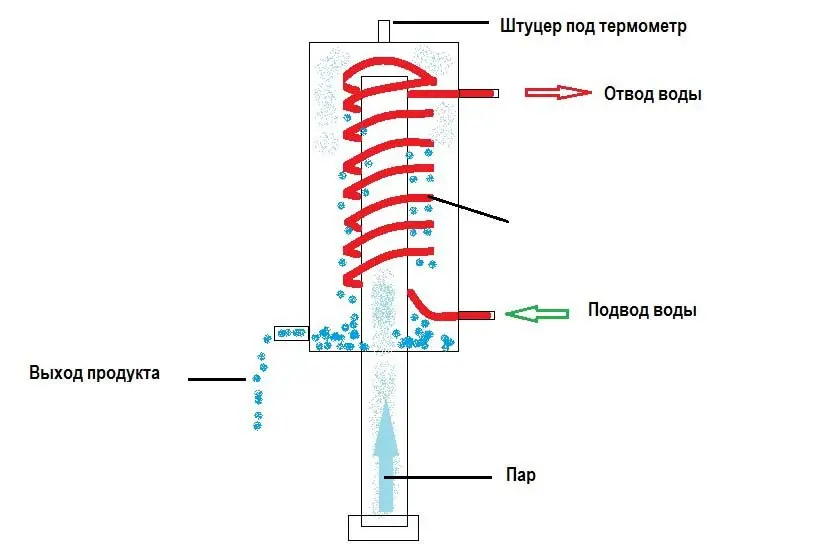

The reflux condenser is named after its creator, the German organic chemist Otto Dimroth (1872-1940). The device is a flask with a spiral inside, cooled by water. Alcohol vapors condense on spirals, then phlegm and drops of alcohol from the lower loop of the spiral in the center fall into the ascending flow of alcohol vapors. This improves re-evaporation.

The only drawback of the Dimroth reflux condenser in comparison with other direct-flow refrigerators is the complexity of its manufacture, which affects the cost. Design advantages: re-evaporation of the condensed alcohol and easy temperature setting during liquid sampling.

Calculation of parameters

The calculation of the required length of the Dimroth refrigerator can be performed using a simplified method, you only need a calculator.

| Parameter | Layer thickness h, m | Thermal conductivity λ, W / (m * K) | Thermal resistance R, (м2K) / W. |

| Contact zone of metal with water, (R1) | 0.00001 | ||

| Dimroth metal (stainless steel λ=17, copper – 400), (R2) | 0.001 | 17 | 0.00006 |

| Phlegm, (R3) | 0.001 | 1 | 0.001 |

| Metal-steam contact zone (R4) | 0.0001 | ||

| Total thermal resistance (Rs) | 0.00117 | ||

| Heat transfer coefficient (K), W / (m2TO) | 855.6 | ||

| Correction factor taking into account centrifugal forces in the coil and flow turbulence, (Em) | 1.44 | ||

| Итоговый коэффициент теплопередачи в Димроте (Кд), Вт/(м2TO) | 1234.1 |

1. Determine the heat transfer coefficient.

Formulas:

R = h / λ, (m2K) / W;

Rs = R1+R2+R3+R4, (м2K) / W;

K u1d XNUMX / Rs, W / (m2TO);

Ет u1d 3,54 + XNUMX * d / D, where d is the diameter of the Dimroth pipe (mm), D is the diameter of the spiral (mm);

Kd uXNUMXd Et * K, W / (m2TO).

2. Determine the average temperature difference between steam and cooling water.

Temperature of saturated alcohol vapor Tp = 78,15 °C;

Water temperature at the entrance to Dimroth (possible range 15-20 °C) – Т1 = 20 °C;

Water temperature at the outlet of Dimroth (possible range 30-40 °C) – Т2 = 35 °C.

Tin = Tp – T1;

Tout u2d Tp – TXNUMX.

The average temperature (Тav) is calculated by the formula:

Tav = (Tin – Tout) / Ln (Tin / Tout).

That is, in our case – rounded: Tin = 58; Tout = 43;

Тср = (58 — 43) / Ln (58 / 43) = 15 / Ln (1,35) = 50 °C.

3. The last stage: based on the known Kd and Tav, determine the required surface area for heat exchange (S) for the required heat power N, (W).

S = N / (Tср * Кд), (м2).

For example, if you need to utilize the power of 3000 W, then the heat exchange surface area:

S = 3000 / (50 * 1234,1) = 0,04832 m2 or 483 cm2.

With a known diameter of the Dimroth pipe d (cm), we find its minimum required length:

L = S / (3,14 * d).

L u483d 3,14 / (0,6 * 256,6) uXNUMXd XNUMX cm.

With a safety factor of 1,2, the length of the Dimroth refrigerator pipe will be:

L dimroth u1,2d XNUMX * L.

L dimroth = 1,2 * 256,6 = 308 cm, which is confirmed by known experimental data.

Counting in progress…

Enter the initial data on the left

Application of Dimroth in practice

Often there are questions about which Dimroth refrigerator is better: single-layer or double-layer? Should the turns be spread apart or is a tight winding better? It is possible to unambiguously answer these questions only by understanding where and for what purpose it will be applied.

Single-layer Dimrots are most often used for beer columns with steam extraction after a reflux condenser and for inclined condensers. It is for BC that Dimrots are made with a bent lower turn in order to center the phlegm flowing into the nozzle. For a stick, the bent lower turn is irrelevant, however, it is necessary to provide gaps between the Dimroth turns so that the phlegm flows more easily and does not create additional thermal resistance during steam condensation.

For an inclined condenser, Dimrot is made with a large gap between it and the walls of the reflux condenser. In the case of a snug fit of the coils to the body, some of these coils are flooded and cease to participate in the condensation of steam, but successfully work on supercooling the phlegm.

Two-layer Dimrots are used both in BC and in RK. First of all, this design allows you to reduce the height of the reflux condenser or condenser, which gives more opportunities to increase the height of the packed part of the column.

A correctly made two-layer Dimroth is approximately 1,5 times more efficient than a single-layer one in terms of utilized power.

Steam, passing along the outer turns of Dimroth, is limited on the one hand by the outer wall, on the other hand, by tightly wound inner turns. This makes it possible to lengthen its path and at the same time heat up the cooling water well on the way to the lower turns of the inner layer, where the bulk of the steam condenses. In general, the condensation zone is stretched, due to which the flowing phlegm is longer in contact with the steam going up and is better heated.

Two-layer dimrots are also made for inclined dephlegmators, but only with extended coils.

When using double-layer dimrots in vertical baffle capacitors, it is imperative to insert a dense tangle of 2-3 cm into them from above into the central cavity. This will increase the utilization capacity of the Dimroth without steam breakthrough into the atmospheric connection tube (TCA).

How to make Dimrot with your own hands

It is better to make Dimrot from a stainless tube with a diameter of 6 mm and a wall thickness of 1 mm. Such a tube bends well and does not require pre-filling with sand or salt. From 8 mm pipes, Dimrots are made mainly for working with autonomous cooling, since it is much easier for low-power pumps.

Copper is acceptable in the manufacture of Dimroth for BC with a selection of steam above the dephlegmator, but you need to be prepared for such a picture (see figure).

If copper Dimrot is installed in the condenser, then the product may be contaminated with copper oxides in the selection.

Making Dimrot is easiest with a lathe.

But if this is not possible, you can make the simplest device (see pictures).

This is a laborious process, but it cannot be called difficult.

The mandrel should be selected based on the inner diameter of the dephlegmator body. For example, the inner diameter is 48 mm, then you need to subtract 2 mm for the gap between the body and the outer turns, then 4 times 6 mm for a two-layer Dimroth – you get 22 mm. Then leave a couple more millimeters of stock and you can wind it on a 20 mm pipe. If Dimrot is copper, then after winding the pipe does not spring.

When making Dimroth from stainless steel, there are nuances: seamless stainless steel winds well, and seam steel can give a strong spring and generally won’t fit into the pipe later, it’s better not to mess with it.

Many prefer not to risk using mandrels a couple of millimeters thinner. In any case, if you take your time and create a good tension when winding, then everything will work out. After finishing winding with a screwdriver and a hammer, you can always trim the gaps so that Dimroth’s refrigerator becomes more beautiful.