Contents

Industrial blowers are multifunctional devices that allow you to create excess pressure (0,1-1 atm) or vacuum (up to 0,5). Usually this is a large equipment with a complex design.

Such devices are able to work for a long time at maximum loads. Industrial units are able to function under water and in adverse conditions.

Applications

Most blowers are versatile devices that can operate in both blowing and vacuum modes.

The main areas of application for industrial blowers are:

- For aeration of water bodies. Due to aeration, water is saturated with air or oxygen. In water purification systems, this makes it possible to eliminate manganese, iron and various volatile substances from the water. As a result, water quality improves. In fisheries, water saturation with oxygen promotes the development of fish and other inhabitants of artificial reservoirs.

- Bulk material handling. Equipment designed to quickly move bulk components is called pneumatic transport. This operation is carried out by vortex devices capable of creating a dense air flow. Pneumatic transport with a blower is easy to use, quickly mounted, operates silently and does not require the installation of additional air drying or cooling systems.

- Keep burning. With the help of industrial equipment, combustion is maintained, which is necessary for firing and drying kilns.

- Drying of films and surfaces covered with varnishes or paints. The air flow created in the blower is used to dry the film. First you need to develop it, after which the required amount of solution is removed by blowing. The film is then dried under vacuum.

- Vacuum related industries. Blowers are actively used in the production of castings by vacuum method, packaging, taking gas samples.

- Ventilation, removal of dust and pollution. The devices can be used as an industrial vacuum cleaner to remove various contaminants. Blowers are used to remove material residues from conveyor belts, weaving machines and other machines.

The main varieties

Depending on the design, there are several types of industrial blowers. They differ in different levels of noise and vibration, performance, engine type. The choice of device depends on the area in which you plan to use it, and its performance.

Piston blowers

Piston-type blowers capture a large amount of air, which is pumped by the translational movement of the piston. Their main advantage is the creation of high working pressure.

Piston blowers are characterized by low cost, high efficiency and versatility. Installations are divided into dry and oil. Dry ones have a shorter service life, give out clean air and are suitable for occasional use.

This type of equipment is considered obsolete, it is being replaced by more productive devices.

Screw blowers

A device of this type contains rotors equipped with blades of complex shape. When they rotate, the air is compressed, after which it is directed through the hole. In the working cavity of such a system there is an oil mixture that reduces friction.

The advantages of screw units are:

- low vibration and noise level;

- no need to prepare the foundation for their installation;

- clean produced air;

- the presence of an automatic control system.

The disadvantages of this equipment include the complexity of the mechanism, high oil consumption at high loads and the high cost of the screw block.

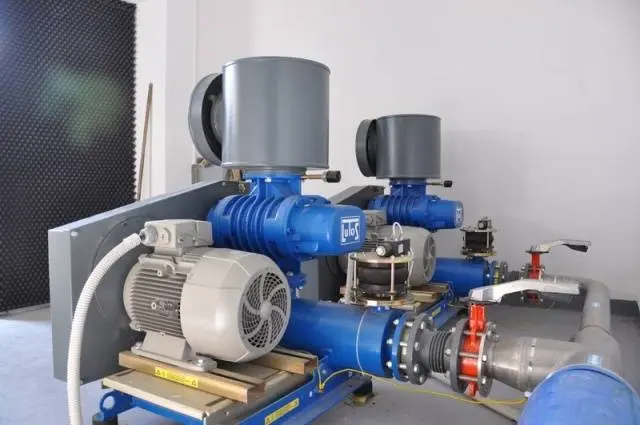

Twin rotor blowers

If it is necessary to obtain high pressure, twin-rotor gas blowers are chosen. Their working cavity has two rotors that rotate synchronously.

These are practical devices that have the following advantages:

- low noise and vibration levels;

- long service life;

- simple construction.

The disadvantage of such devices is the low energy consumption. Another negative factor is the pulsation of the air flow, which creates increased vibrations. As a result, the wear of the mechanism increases.

This impact can be reduced by cushioning cushions and a casing with soundproofing properties.

Centrifugal blowers

These devices are a dynamic radial type compressor. The movement of the air flow in them occurs in a perpendicular direction to the axis of rotation.

The advantages of centrifugal blowers are:

- high performance;

- work in continuous mode;

- low noise level;

- safety due to the absence of interaction between gas and oil;

- compactness;

- the convenience of use.

Their disadvantages include the need for lubrication and additional cooling.

Submersible blowers

The submersible type device is designed for installation at the bottom of water bodies. Water provides cooling of the case, which increases the life of the mechanism. The submersible equipment is silent and fully automated.

Turboblowers

Turboblowers are used for high compressed air consumption. Their principle of operation is similar to centrifugal devices. Air is injected under the action of centrifugal force, which is ensured by the rotation of the impeller.

Turboblowers are divided into single-stage (create a head above 3, but not more than 6 m) and multi-stage (pressure up to 30 m). Such devices are suitable for aeration, conveying materials, creating air curtains, drying containers and removing moisture from surfaces prior to final coating.

Whirlpool blowers

Vortex-type devices have side channels in which the gas is repeatedly exposed through the impeller. As a result, kinetic energy is increased and high pressure is provided.

The vortex equipment operates almost silently, is characterized by compact dimensions and high reliability. During its operation, there are no vibrations and pulsations of air flows.

According to the KDP, such devices are inferior to centrifugal models. Another disadvantage is the need to use a filter, since the ingress of foreign objects can damage the device.

Electric blowers

In electrical units, air is supplied by the operation of an electric motor. Such equipment has a lower cost compared to mechanical devices.

Criterias of choice

The main requirement for industrial blowers is to meet the demand for compressed air. There is no need for a large reserve, since in emergency situations, reserve equipment is used.

Depending on the purpose of the device, you need to pay attention to the following nuances:

- air flow quality (requirements for dryness, absence of foreign particles);

- operation in vacuum mode;

- features of the service, its cost and simplicity (this item of expenditure should be less than 1% of the cost of the device);

- noise level, especially if the equipment operates near a residential area.

blower manufacturers

The main manufacturers of blowers are European companies that supply productive and high-quality equipment. Each firm specializes in the production of a certain type of product.

Foreign manufacturers

The main foreign manufacturers of this industrial equipment are:

- Busch. One of the largest compressor manufacturers based in Germany. The company produces twin-rotor (Tyr models) and vortex blowers (Samos models).

- Becker. Another German manufacturer that deals with industrial vacuum equipment. The range of manufactured products includes oil-free, vortex and screw compressors. The devices comply with environmental standards and are characterized by stable operation.

- collapse. Czech company producing rotary and screw devices for water treatment, transport of substances, mixing gases and other applications. Gas blowers are presented in two series: DT and VAN.

- Robust. An Italian manufacturer that specializes in the production of screw and rotary devices.

- Elmo Rietschle. A German company that produces a wide range of blowers. Vortex, rotary and centrifugal devices are characterized by low noise levels and the ability to work with hot gases.

- FPZ. An Italian company producing one- and two-stage vortex devices capable of operating in an aggressive environment.

- Atlas Copro. The Swedish company produces oil-free rotary and centrifugal units that comply with the ISO standard. The produced equipment allows to save energy consumption due to the frequency-controlled drive. The monitoring system monitors system performance and provides information about faults.

Р РѕСЃСЃРёР№СЃРєРёРµ РїСЂРѕРёР · водители

Domestic manufacturers of blowers are:

- SSM. SpecStroyMachine is a company that manufactures blowers. The range includes devices of rotary and centrifugal type. Industrial units provide oil-free air compression at low pressure and high performance. The product range includes series BP, BP GE, BC and others, which differ in technical characteristics.

- SPKZ “ILKOM”. St. Petersburg Compressor Plant produces vortex and centrifugal devices of various designs.

- ALTERNATIVE. manufacturer supplying the market with a wide range of vortex devices and turbo blowers.

Conclusion

The industrial blower is a versatile device capable of performing a wide range of tasks. Such equipment allows you to effectively eliminate pollution, enrich water with oxygen, move bulk solids, dry the surface, etc.

The choice of blower design depends on the conditions in which it is to be used. The cost of maintenance and repair, dimensions and technical characteristics of the device must be taken into account.

Leading positions in the compression equipment market are occupied by foreign companies producing a wide range of blowers.