Contents

Having your own wind generator is very beneficial. First, a person receives free electricity. Secondly, electricity can be obtained in places remote from civilization where there is no power line. A windmill is a device designed to generate the kinetic energy of the wind. Many craftsmen have learned how to assemble a vertical wind generator with their own hands, and now we will find out how this is done.

Device and varieties of windmill

Wind generators have many names, but it is more correct to designate them as a wind farm. The wind farm consists of electrical equipment and a mechanical structure – a windmill, which are interconnected into a single system. An electrical installation helps turn wind into a source of energy.

There are many varieties of wind turbines, but according to the location of the working axis, they are conditionally divided into two groups:

- Windmills with a horizontal axis of rotation are the most common. The electrical installation is characterized by high efficiency. In addition, the mechanism itself resists hurricanes better, and in light winds, the rotor starts faster. Horizontal wind generators are easier to regulate power.

- Windmills with a vertical axis of rotation are able to work even with low wind speeds. Turbines do not make noise and are easier to manufacture, so most often they are installed by craftsmen in their yard. However, the design feature of a vertical windmill allows it to be installed only low from the ground. Because of this, the efficiency of the electrical installation is greatly reduced.

Wind generators differ according to the type of impeller:

- Propeller or vane models are equipped with blades that are perpendicular to the working horizontal shaft.

- Carousel models are also called rotary. They are typical for vertical windmills.

- Drum models similarly have a vertical working axis.

To generate the kinetic energy of wind on an industrial scale, propeller wind turbines are usually used. Models of drum and carousel type are characterized by large dimensions, as well as a less efficient mechanism.

All windmills can be equipped with a multiplier. This gearbox makes a lot of noise during operation. In home windmills, multipliers are usually not used.

The principle of operation of the windmill

It should be noted that the principle of operation of the wind generator is the same, regardless of its design and appearance. Energy generation begins from the moment the windmill blades rotate. At this time, a magnetic field is created between the rotor and the stator of the generator. It also serves as a source of energy that generates electricity.

So, as we found out, a wind generator consists of two main parts: a rotating mechanism with blades and a generator. Now about the work of the animator. This gearbox is installed on a windmill to increase the speed of the working shaft.

During the rotation of the generator rotor, an alternating current is generated, that is, three phases come out. The generated energy goes to the controller, and from it goes to the battery. In this chain there is another important device – the inverter. It converts the current to stable parameters and supplies it to the consumer through the network.

Windmill industrial craft 2

In the field of wind energy, the industrial craft 2 kinetic wind generator, which has a modified block for generating wind energy, is very famous. To calculate the power of an electrical installation, the sum of the speeds of its working bodies is multiplied by a value of 0,1. The size of the working area is determined by the dimensions of the rotor. During rotation, it generates kinetic kU, not electrical energy EU.

The rotation of the blades depends on the gusts of wind. The most optimal speed is observed at an altitude of 160-162 m. A thunderstorm increases the wind speed by 50%, and a simple rain – up to 20%.

The rotors of the industrial craft 2 wind generator differ in the dimensions and material of the blades, as well as the limiting wind strengths at which they are able to operate:

- a wooden rotor with 5×5 blades is designed for wind speeds from 10 to 60 MCW;

an iron rotor with 7×7 blades is designed for a speed range – from 14 to 75 MCW;

- a steel rotor with 9×9 blades is designed for a range of air flow rates from 17 to 90 MCW;

- The carbon fiber rotor with 11×11 blades is designed for a range of airflow rates from 20 to 110 MCW.

Industrial craft 2 kinetic wind turbines are not placed close to the same level with their backs to each other.

Self-manufacturing of a vertical wind generator

In self-manufacturing, a vertical shaft windmill is the easiest. The blades are made from any material, the main thing is that it is resistant to moisture and the sun, and also light. For the blades of a home wind generator, you can use a PVC pipe used in the construction of sewers. This material meets all of the above requirements. Four blades 70 cm high are cut out of plastic, plus two of the same are made of galvanized steel. Tin elements are shaped into a semicircle, after which they are fixed on both sides of the pipe. The remaining blades are fixed at the same distance in a circle. The radius of rotation of such a windmill will be 69 cm.

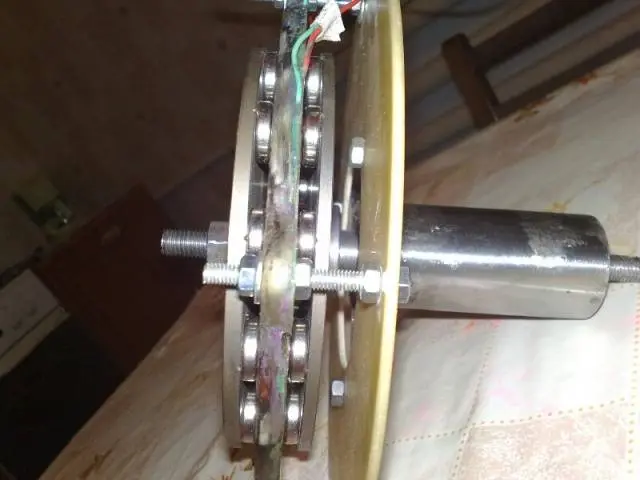

The next step is to assemble the rotor. Here you need magnets. First, two ferrite disks with a diameter of 23 cm are taken. Using glue, six neodymium magnets are attached to one disk. With a magnet diameter of 165 cm, they form an angle of 60о. If these elements are smaller, then their number is increased. Magnets are glued not just randomly, but alternately change the polarity. Ferrite magnets are attached to the second disk in a similar way. The entire structure is abundantly filled with glue.

The hardest part is making the stator. You need to find a copper wire 1 mm thick and make nine coils out of it. Each element must contain exactly 60 turns. Further, the electrical circuit of the stator is assembled from the finished coils. All nine of them are laid out in a circle. First connect the ends of the first and fourth coils. Next, the second free end of the fourth is connected to the output of the seventh coil. The result was an element of one phase of three coils. The scheme of the second phase is collected from the next three coils in sequence, starting from the second element. The last one is collected in the same way the third phase, starting from the third coil.

To attach the circuit, a shape is cut out of plywood. Fiberglass is placed on top of it, and a circuit of nine coils is laid out on it. All this is poured with glue, and then left until completely solidified. Not earlier than a day later, the rotor can be connected to the stator. First, the rotor is placed with the magnets up, the stator is placed on it, and the second disk is placed on top with the magnets down. The principle of connection can be seen in the photo.

Now it’s time to assemble the wind generator. Its entire circuit will consist of an impeller with blades, a battery and an inverter. To increase the torque, it is desirable to install a gearbox. Installation work is as follows:

- A strong mast is welded from a steel corner, pipes or profile. In height, it should raise the impeller with blades above the roof ridge.

- The foundation is poured under the mast. Be sure to make reinforcement and provide anchors protruding from concrete.

- Next, the impeller with the generator is fixed to the mast.

- After installing the mast on the foundation, it is fastened to the anchors, after which it is reinforced with steel braces. For these purposes, a cable or steel bar with a thickness of 10–12 mm is suitable.

When the mechanical part of the wind generator is ready, they begin to assemble the electrical circuit. The output generator will give a three-phase current. To obtain a constant voltage, a diode rectifier is placed in the circuit. Battery charging control is carried out through a car relay. The inverter circuit completes the chain, from which the required 220 volts goes into the home network.

The output power of such a wind generator depends on the wind speed. For example, at 5 m/s, the electrical installation will give out about 15 watts, and at 18 m/s, you can get up to 163 watts at the output. To increase productivity, the windmill mast is extended to 26 m. At this height, the wind speed is 30% higher, which means that electricity will be about one and a half times more.

The video shows the assembly of a generator for a windmill:

Building a wind turbine is a tricky business. You need to know the basics of electrical engineering, be able to read diagrams and use a soldering iron.